-14-

Appendix A: Theory Of Operation

A.1 Pre-Filters

The pre-filters have two purposes, one is to clean the water for better consump-

tion, and the second is to prevent the RO membrane from being polluted. The first

stage filter removes sediment materials such as sand, rust, pipe scale, and dirt. It is

made of a spun polypropylene material that will take out particles down to 5 -

microns.

The water then goes to the carbon block filters, which are important for two rea-

sons. The first takes out 90% of the chlorine in the water thereby protecting the RO

membrane from damage by the presence of chlorine. It also removes the taste of the

chlorine, as well as other tastes and odors that affect the drinking water . (The carbon

accomplishes this by adsorption on its surface). This is a chemical/mechanical

process unique to carbon that has been activated -made to have high surface area. The

second Carbon Block filter is there to also takes out VOCs (volatile organic chemi-

cals) which are contaminants from industrial pollution.

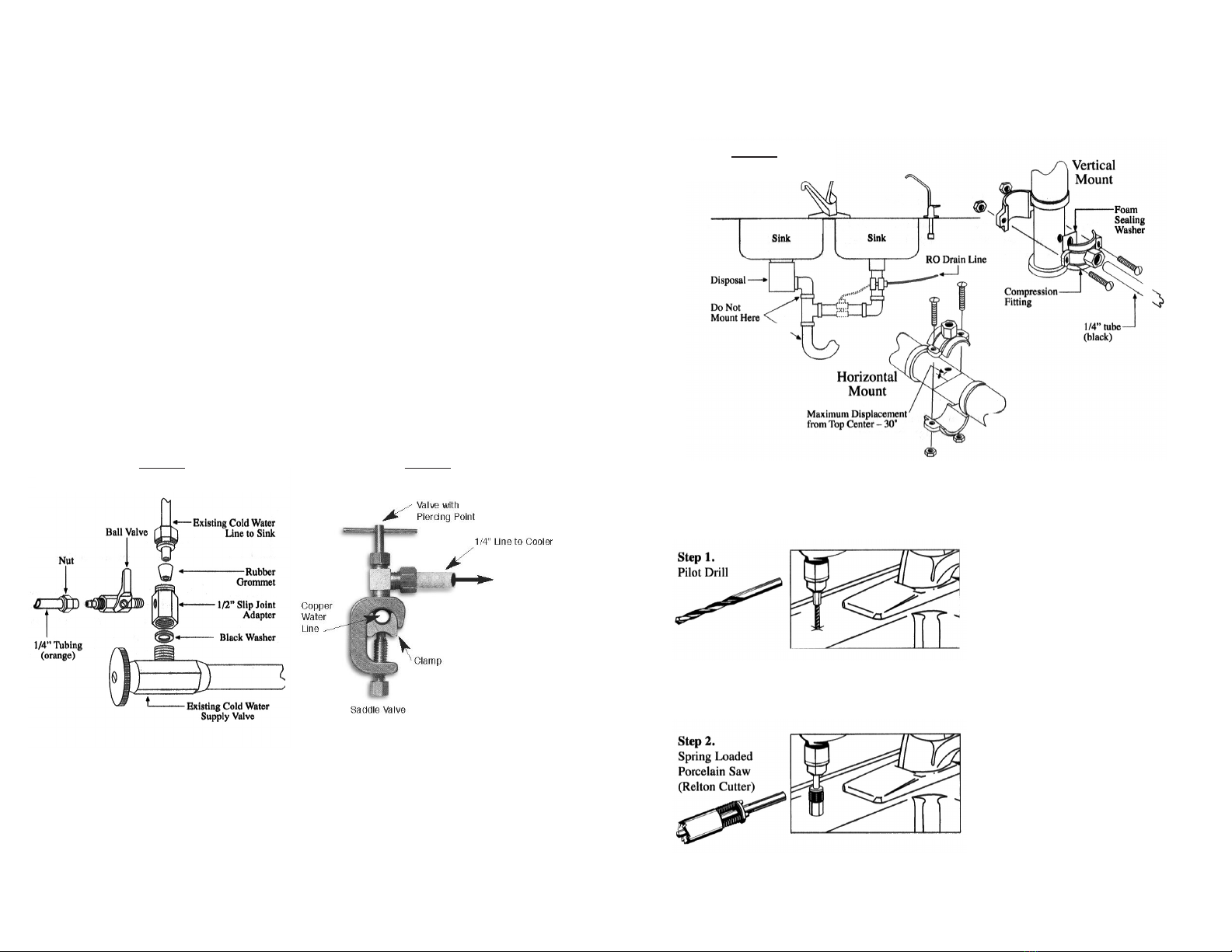

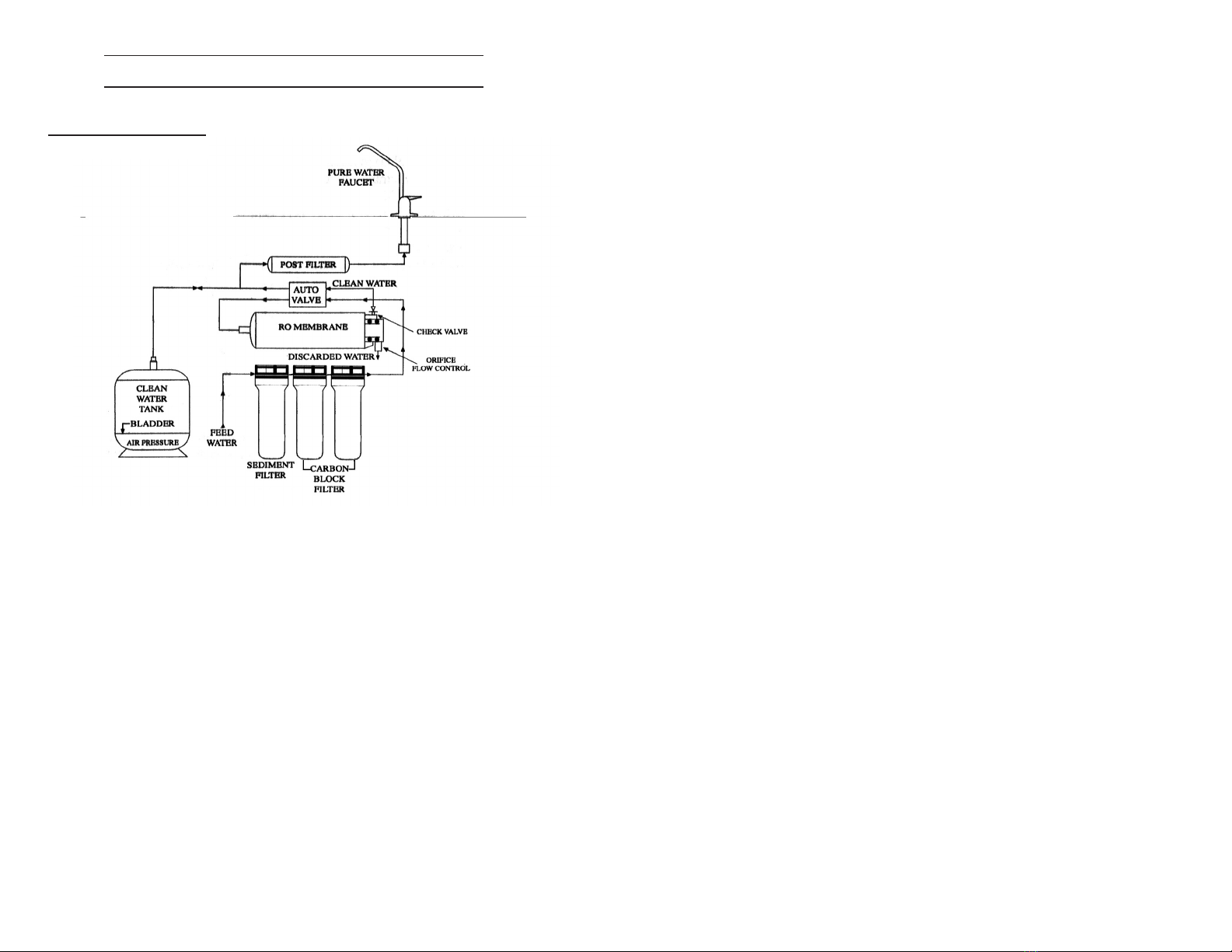

Flow Schematic (Figure A-1)

-15-

A.2 The Reverse Osmosis Membrane

This is the heart of the machine, and the great protector. The membrane is a replica-

tion of human or animal stomach tissue, which permits the water molecule to pass

through, but holds the dissolved molecules back. This occurs naturally by osmotic pres-

sure developed because of the content of dissolved solids. To make this happen with the

RO membrane we reverse the osmotic pressure by applying pressure to the water (revers-

ing the process of generating pressure) to push the water molecules through the mem-

brane, but keeping most of the dissolved solid molecules behind. “Most” means about

70% of nitrates and 99% of copper, lead, and other high molecular weight material.

The reverse osmosis technology will, on average, reject 93% of the total dissolved

solids in the incoming water. Over time, the RO membrane will foul with a very thin

layer of materials and the efficiency will drop, so that the TDS content of the clean water

will rise. When it rises to greater than 30% of the inlet TDS value, it is an indicator that

the RO membrane should be replaced. This occurs every 3-4 years. (See Section 4)

About 4 gallons of water is discarded for every gallon of pure water made. In

Figure A- 1, the discard is shown with a flow control orifice at the outlet of the RO

stage. This is designed to hold back the discard water to the above ratio, and maintain

pressure on the water in the membrane. For a 75-gallon per day membrane, approxi-

mately 668 milliliters per minute of water are discarded. Note there is a check valve

on the clean water outlet from the RO. The purpose is to prevent backflow of water

to the membrane from the tank or faucet or because of autovalve failure. In the aver-

age household, about 3 gallons of drinking water are used a day.

A.3 Auto Control

As water is produced the pressure in the storage tank increases. To stop production

of water when the tank is full, an auto control valve is used in the system, as shown in

Figure A-1. The pressure in the tank is set nominally to be 2/3 of the incoming line

pressure. When this ratio is reached the autovalve will close. Normal U.S. city water

pressure is 60-psi, therefore the tank pressure, when water flow stops, is 40-psi.

The purified water goes to the tank where it is stored at pressure as described

above. The tank has a bladder in it, and on one side is air at 6-psi, initially. The ini-

tial volume of the storage tank is 4.0 gallons. As the water fills the tank, it pushes

against the bladder, and raises the pressure as it takes space in the tank. When the pres-

sure increases to 40-psi, water flow stops. The net amount of water in the tank when

full, less the space taken by the air at 40-psi is approximately 2.5 gallons. When

water is drawn through the clean water faucet on the sink, the water flows through

the final activated carbon post filter, which polishes the water by taking out any stal-

eness which has set in.When water is supplied to the refrigerator, the line should be

therefore taken after the post filter.

When the raw feed water pressure available is 40-psi or less, the RO membrane

will not operate efficiently or produce water at a reasonable rate. To overcome this use

a system with a booster pump which will raise the water pressure in the system to

about 80-psi.

Rev. 8/08

Copyright VERTEX Industrials, Inc. 2008