-6-

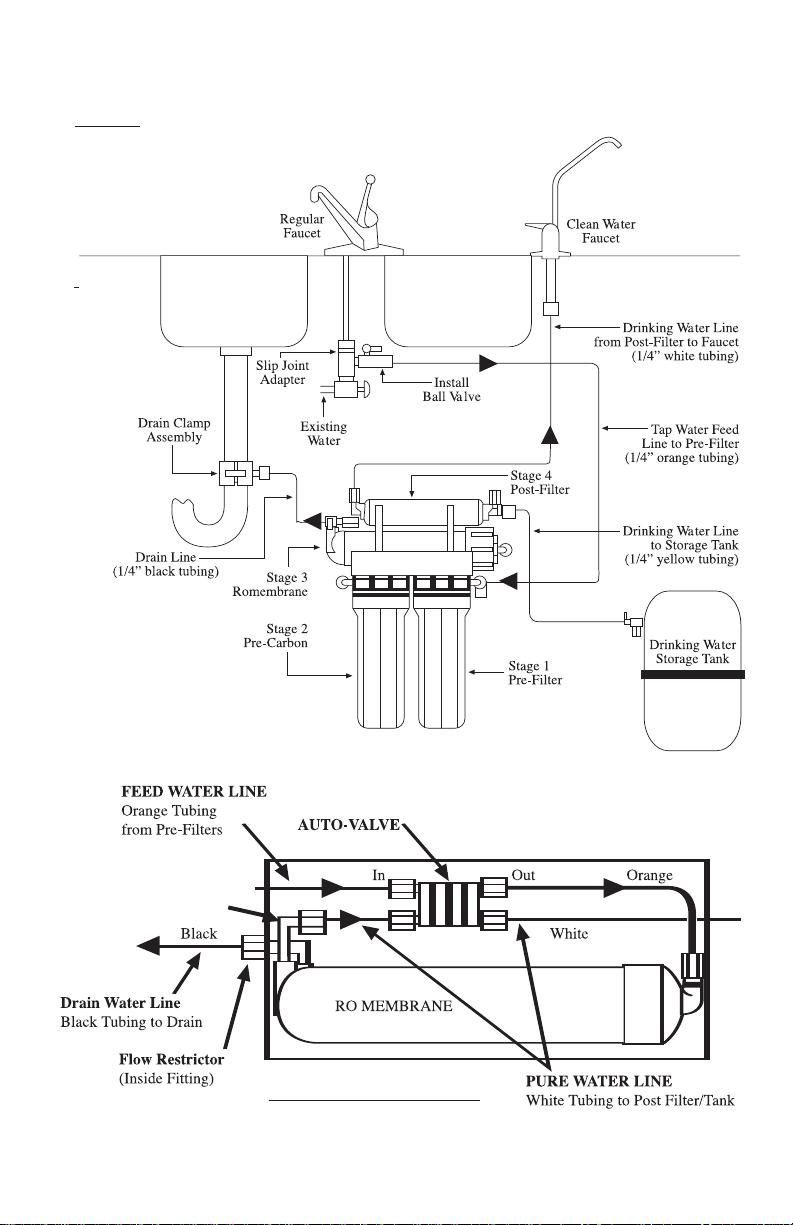

2.6 Installation of clean water faucet (Fig. 6)

The faucet should be positioned

with aesthetics, function, and con-

venience in mind. An ample flat

area is required for the faucet base

so that it can be drawn down tight.

The space under the sink below

where the faucet will be mounted

must be clear of any obstructions.

Some conditions may eliminate

the need to drill a hole in the sink

such as a faucet previously

installed in the sink, a hole cov-

ered by a chrome hole cover, or an

unused spray handle. If any of

these situations are present, you

may mount the faucet in one of

these holes.

The sink drilling process is not

complicated, but requires a certain

amount of caution and fore-

thought. Porcelain sinks can be

chipped if care is not exercised

when drilling the hole for the

faucet.

[NOTE: This procedure is for the non air gap faucet provided.]

2.7 Porcelain/Enamel over Steel or Cast Iron Sinks

Using a small diameter carbide tipped drill, drill a pilot hole completely through the

porcelain and the material underneath. Remove any metal chips that fall into the sink to

prevent rust stains. Place the spring-loaded porcelain cutter bit in to the drill chuck. Make

sure the pilot guide is insertedtightly. Insert the pilot guide onto the pilot hole. Push down

gently on the drill motor to apply light pressure to the porcelain surface. Start the drill

motor, turning as slowly as possible. After the initial cut has started, motor speed may be

gradually increased. The cut may require three to four minutes to complete. Going faster

could result in excessive chipping. Be sure a complete ring has been cut through the porce-

lain to the metal underneath.

Place the finish hole saw into the drill chuck. Make sure the pilot guide is inserted

tightly. Insert the pilot guide into the pilot hole. Begin cut using a slow speed and light

pressure until the porcelain has been penetrated to the material underneath. Remove the

saw from the hole and clean all debris from the porcelain surface. Reinsert saw into the

hole and cut through the remaining material.

Step 1.

Pilot Drill

Step 3.

Finish Hole

Saw

Step 2.

Spring Loaded

Porcelain Saw

(Relton Cutter)