Rev.15‐03‐20177

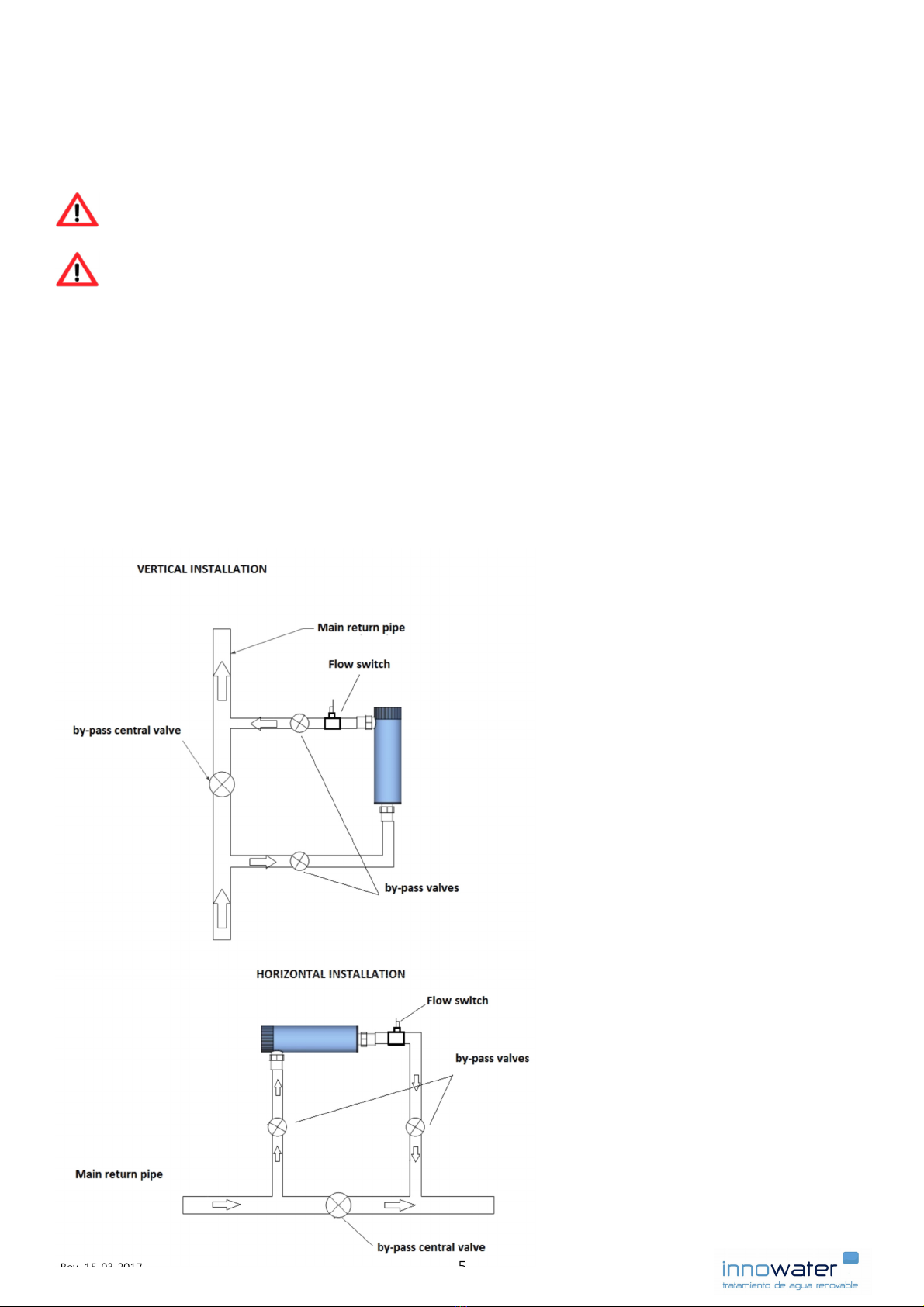

Beforestarngthepumpforthefirstme,openthecentralby‐passvalvefullytoavoidanyoverpressurein

thecellhousing.Oncethepumpisrunning,opentheinletandoutletvalvesslowlyunltheyarefullyopen.

Youcanthenparallyclosethecentralvalveinordertosendtheflowthroughthecellunlyouhavearapid

anuniformflow.Thewatermustflowatasufficientspeedthoughtthecell.Iftheflowistoolowscalecould

buildontheelectrodes.Iftheinstallaonisnotprovidedwithadedicatedpumpforthechlorinator,adjust

theflowratebyacngontheby‐passcentrevalve.

Whenthecellisbeingfilledtheairtrappedinthecellhousingcanpreventthewatertoflow.Youcantem‐

porarilyloosetheflowswitchinordertoevacuatetheairinside.Oncethecellhousingiscompletelyfilled,

don’tforgettoreghtentheflowswitch.Verifythatthearrowmarkingontheflowswitchcorrespondsto

thewaterflowaerreghtening.

6. ELECTRICAL CONNECTIONS

Power supply cable

Thechlorinatormustbepoweredto230VAC.Connectthethree‐wirepowersupplycable(marked“230VAC

powersupply”)toapermanent230VACmainspowersupplywithprotecveearth.Thevoltageonthiscable

mustbekeepconstantaslongasthechlorinatorisinuse.DO NOT INTERRUPT the power on this cable

alongthepumpworkingcyclesorbymeansofanyothercontroldevice.Inordertocontrolthechlorinator

produconcyclesusetheExternal Control Cable.Disconnectthepowersupplyonlywhenyouarenotgoing

tousethechlorinatororincaseoffault.

The chlorinator must imperavely be connected to a protecve earth through its power supply cable

and protected by a 30 mA residual circuit breaker.

External Control Cable

Thetwo‐wirecablemarked“EXTERNAL CONTROL 230VAC”isusedtostartandstopthechlorineproducon

synchronicallywiththepumpworkingcyclesorbymeansofacontroldevice.Whenthevoltageappliedbe‐

tweenthetwowiresis230VACthechlorinatorwillproducechlorine.Whenthevoltagebetweenthewiresis

0VACthechlorinatorwillhaltthechlorineproduconandenterapausemode.Therefore,thevoltageap‐

pliedtothecontrolcablemustbedrivenbythesamemeans,signalordevicethatpowersorcontrolsthe

pump.

Make sure that the voltage applied to the External Control Cable is 230VAC ONLY when the pump is

running and the water flows freely through the cells and to the pool.

6. OPERATION

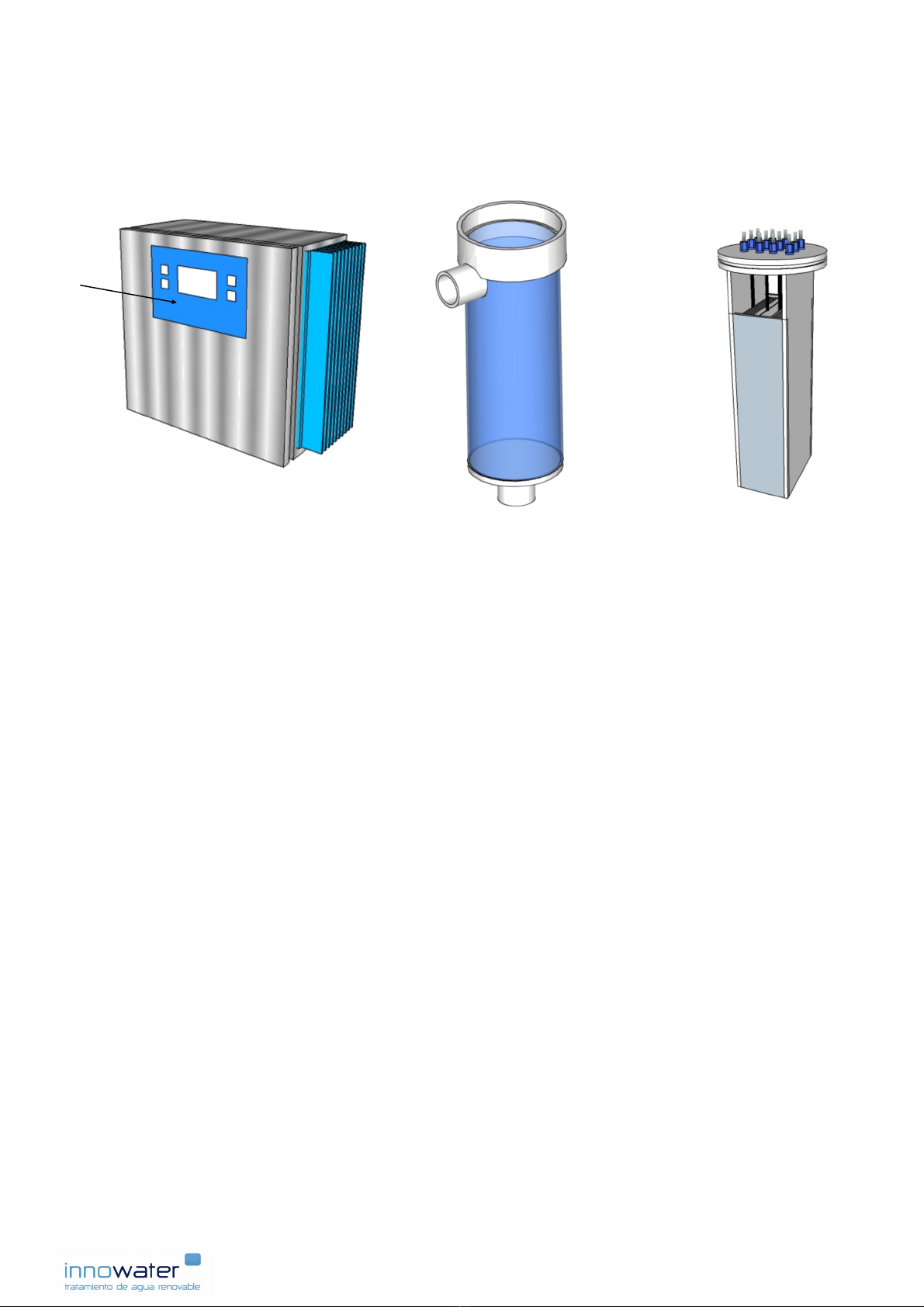

TheSMC50‐75celliscontrolledbymeansofakeyboardandadisplay.Inaelectrolyccell,chlorinegenera‐

onisproporonaltotheelectricalcurrentflowingthroughit.TheSMC50‐75willtrytomaintainaconstant

electricalcurrentinthecellaccordingtothechlorineproduconrate(0—100%)setbytheuser.Thevalues

ofcurrentandvoltageinthecellareconstantlydisplayedinthemainscreen.Innormalcondionsandat

100%produconratethecurrentvalue(I1)mustbeasfollows:

SMC50:7.0Ato8.5A SMC75:11.0Ato13.5A