deconta AS 300 CG User manual

Instruction manual

Waste water filtration unit

AS 300 CG

Manufacturer: deconta GmbH

Im Geer 20, D - 46419 Isselburg

Descriptioin / Type-No.: AS 300 CG Typ 539

Instruction manual

AS 300 CG

Seite 2

Table of contents

on page

1 Introduction 3

2 Basic safety advice 4

2.1 Intended use 4

2.2 Operation 4

3 Transport 5

31. Delivery 5

3.2 Transport 5

3.3 Storage 5

4 Scope of delivery 6

5 Technical description 6

5.1 Unit description 6

5.2 Effectiveness of waste water filtration 7

6 Technical data 8

6.1 Connections, Dimensions, Weights 8

6.2 Waste water pump 8

6.3 Filter system 8

7 Initial operation 9

7.1 Initial operation with waste water hose and proximity switch 10

8 Maintenance and care 12

8.1 Daily care 12

8.2 Filter change 12

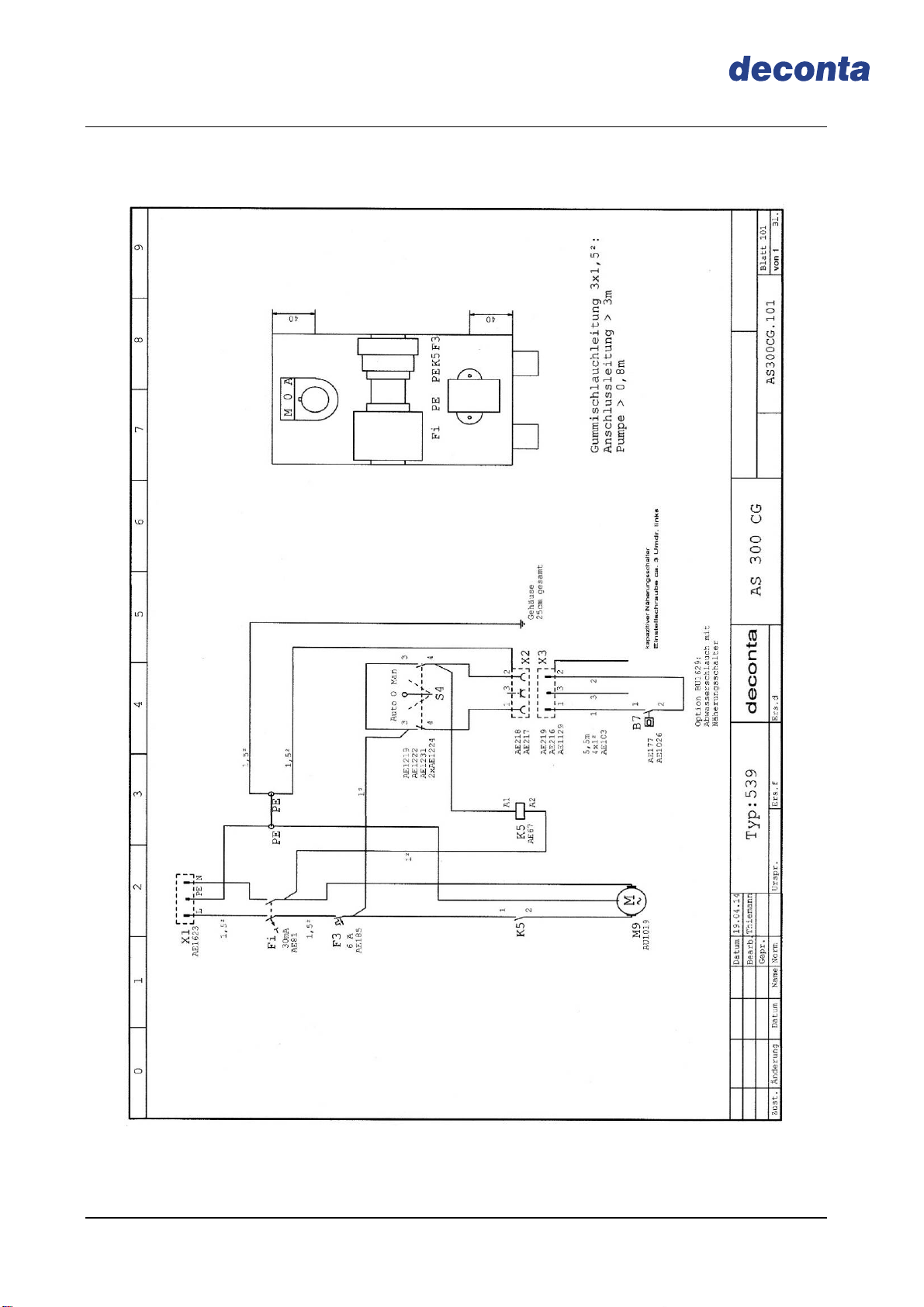

9 Circuit diagram 14

10 Declaration of conformity 15

Instruction manual

AS 300 CG

Seite 3

1 Introduction

Dear customer,

Thank you for choosing a deconta product!

With this device you obtain a practical solution with simple operation, which was

completed in a compact and functional way.

The deconta products guarantee:

Stability, long life and serviceability on site

Mechanics with „kick“

Pleasing design

The copyright of this instruction manual remains with deconta. This manual is intended

for assembly, operation and maintenance personnel. It contains instructions and drafts of

technical nature which may neither be distributed nor used in any unauthorised way for

competitive purposes or passed on to others.

For more information, please visit our website www.deconta.com

Instruction manual

AS 300 CG

Seite 4

2 Basic safety advice

The handling of the appliance technology is only allowed for instructed staff. The exact

knowledge of the instruction manual is an important condition for your staff before

handling the machine.

2.1 Intended use

As an operator, you are obliged by deconta to follow the instruction manual and to use

this engineered technology equipment only in accordance with the regulations and its

suitability! In the event of non-observance, deconta assumes no liability.

2.2 Operation

In order to ensure the safety during the operation of the device, the following must be

observed:

Do not use in hazardous areas.

Necessary repairs, maintenance and cleaning, in particular in the field of electrical

equipment is to be realized by qualified staff

Keep safety and protective equipment in perfect function.

Attached safety instructions are to be kept in a readable state and are to be

followed.

To ensure safety, changes to the unit are prohibited.

ATTENTION!

The Waste water filtration unit is not suitable for the use in condensed, corrosive,

flammable and explosive compartment air. The ambient and medium temperature

must be between +5 and +50°C.

Protect against moisture!

Instruction manual

AS 300 CG

Seite 5

3 Transport

3.1 Delivery

If no other agreements have been made, the unit is packed safely and will be delivered

ex work. Transport damages have to be documented immediately upon delivery by the

carrier or another supplier. Please note the possible damages additionally on the way bill.

The Transport is to be proceeded with care to avoid damages by improper handling or

carelessness.

3.2 Transport

It is important to avoid exposure to violent shocks, otherwise the function and safety of

the unit cannot be guaranteed. In winter and at risk of frost, the whole unit (waste water

pump and filter housing) needs to be emptied before transport.

3.3 Storage

In order to avoid damages, the installation has to be kept in a dry area with no access for

unauthorized persons.

Because of risk of frost in winter it is important to observe the following:

Drain the water pipes and empty filter housings

Drain the water pump through the drain screw

Place the water treatment system in a frost-protected area

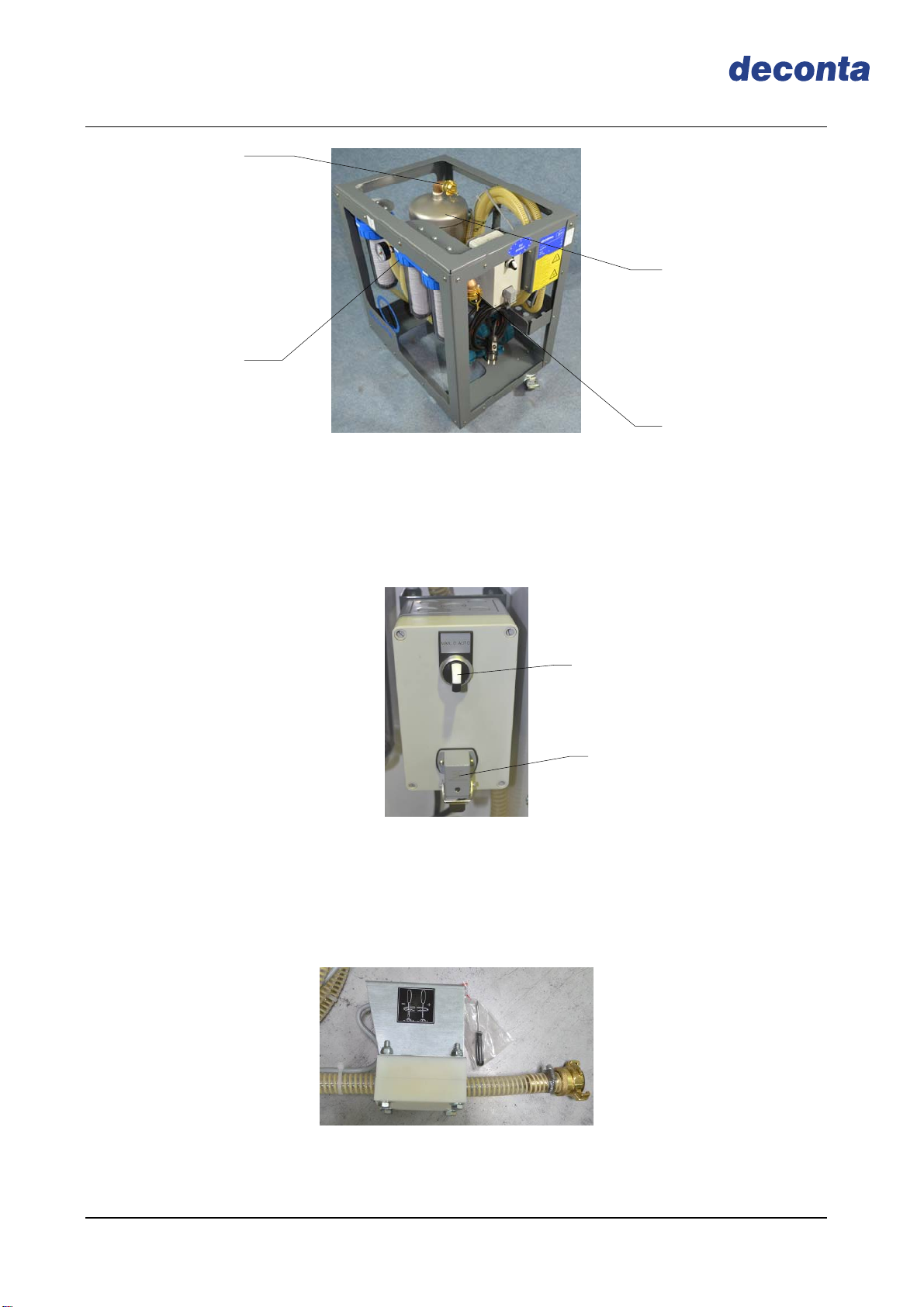

Ventilation connection

Drain screw

Instruction manual

AS 300 CG

Seite 6

4 Scope of delivery

If no other agreements have been made, the scope of delivery of the waste water

filtration unit consists of:

Waste water filtration unit

2x Geka-coupling leak proof

2x Hose clamp

Filter head screw

Instruction manual

5 Technical description

5.1 Unit description

The waste water contaminated with asbestos fibres is cleaned via a 4 stage filtering unit

composed of a coarse pre-filter (bag filter 220µ), rinsing filter 220, fine filter 50and fine

filter 1. In case of very heavy polluted waste water the coarse pre-filter protects the

following filter stages against heavy and fast soiling.

The state of the filter is controlled by a manometer.

The entire unit is located in a powder-coated steel iron housing with standard Geka-

connections.

Instruction manual

AS 300 CG

Seite 7

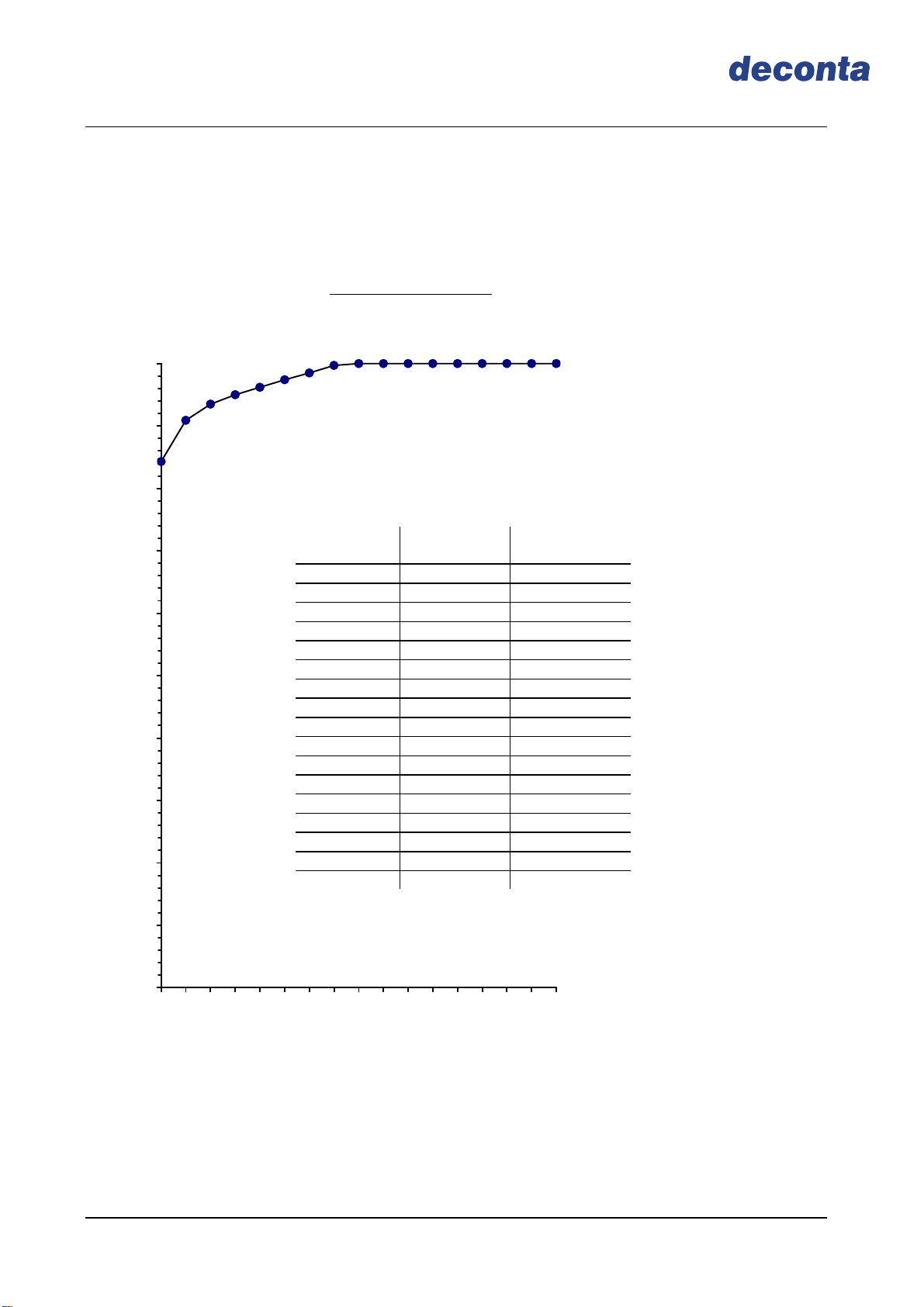

5.2 Effectiveness of waste water filtration unit

Test: Filter separation wound candle 1 Micrometer

Diameter in Micrometer

1

2345678 9 10 11 12 13 14 15 16 17

0

10

20

30

40

50

60

70

80

90

100

0,77

0,97

1,22

1,54

1,93

2,44

3,07

3,87

4,87

6,14

7,74

9,75

12,3

15,5

19,5

24,6

30,9

Measuring

point Diameter %

Effectiveness

1 0,77 84,3

2 0,97 90,4

3 1,22 93,5

4 1,54 95,0

5 1,93 96,2

6 2,44 97,4

7 3,07 98,5

8 3,87 99,7

9 4,87 99,8

10 6,14 100,0

11 7,74 100,0

12 9,75 100,0

13 12,28 100,0

14 15,47 100,0

15 19,49 100,0

16 24,56 100,0

17 30,94 100,0

Instruction manual

AS 300 CG

Seite 8

6 Technical data

6.1 Connections, Dimensions, Weights

Power connection: 230V 50Hz

Personal protection: FI-Switch 30mA

Hose connections System Geka

Dimensions (L x W x H): 655 x 462 x 775 mm

Weight: ca.56 kg

6.2 Waste water pump

Self-priming and safe to run dry

Voltage: 230V, 50Hz

Capacity: 0,45 kw

Flow capacity max.: 30 l/min

max. medium temperature: 90°C

Fuse type: IP44

6.3 Filter system

4- stage filtering unit

Bag filter: 220 µ (reusable)

Pre filter: 10" 220(disposable)

Fine filter: 20" 50(disposable)

Fine filter: 20" 1(disposable)

max. medium temperature: 50°C at 4bar

technical changes reserved

Instruction manual

AS 300 CG

Seite 9

7 Initial operation

Before the initial operation of the waste water pump or after a long period of stagnation,

check that the shaft rotates freely when turned by hand. To this put a screwdriver in the

notch of the shaft end on the fan side and move the shaft. The strong initial rotational

resistance of the new pumps will come loose after running.

Fill waste water pump fully through vent connection

Tighten the cap nut of the filter housing by hand

Connect waste water hose with proximity switch at „IN“ of the coarse pre filter and

then connect to place of use (only use spiral hose)

Connect „OUT“ with sewer

Establish power supply 230V, 50Hz (Schuko plug)

Connection „OUT“

Connection „IN“

Cap nut

Coarse pre-filter

Instruction manual

AS 300 CG

Seite 10

Switch on unit (Position „MAN“ at selector switch) and check, if filter housings are

filling with water

7.1 Initial operation with waste water hose with proximity switch

As an option, a waste water hose with proximity switch for electrical and automatic

On/Off switch function is available.

Before the initial operation of the waste water pump or after a long period of stagnation,

check that the shaft rotates freely when turned by hand. To this put a screwdriver in the

notch of the shaft end on the fan side and move the shaft. The strong initial rotational

resistance of the new pumps will come loose after running.

Fill waste water pump fully through vent connection

Tighten the cap nut of the filter housing by hand

Selector switch

Instruction manual

AS 300 CG

Seite 11

Connect waste water hose with proximity switch at „IN“ of the coarse pre filter and

then connect to place of use (only use spiral hose)

Establish power supply for proximity switch

Connect „OUT“ with sewer

Establish power supply 230V, 50Hz (Schuko plug)

Switch on unit (Position „AUTO“ at selector switch)

The proximity switch at the waste water hose recognizes, if there is water in the hose and

switches the Waste water unit automatically on or off. The sensitivity of the proximity

switch may be readjusted with help of the screw driver, added to the delivery.

Selector switch

Power supply

Proximity switch

Connection „OUT“

Connection „IN“

Cap nut

Coarse pre filter

Instruction manual

AS 300 CG

Seite 12

8 Maintenance and care

8.1 Daily care

Check hoses for free flow

Visual check of 220µ-Pre filter for dirt

Control of fine filter via manometer

8.2 Filter change

The Bag filter inserted in the coarse pre filter may be removed, cleaned and reused.

The Manometer controls the fine filter. We recommend a filter change at approx. 3bar.

Attention:

Change Filter only when device is switched off

Demount dirty filters only in wet shape to avoid contamination

Use approved filters only

Do not use damaged filter candles

Coarse pre filter with

bag filter 220µ

Pre filter 220µ

Fine filter 5µ

Filter head screw

Pre filter 1µ

Cap nut

Manometer

Instruction manual

AS 300 CG

Seite 13

Filter change:

Loosen cap nut with help of filter head screw

Remove filter and dispose of it

Insert new filter candles

Pay attention to correct fit and cleanliness of the seal ring

Tighten cap nut by hand

The suction hoses, pumps, filter housings and filter are contaminated after the first

use. Repairs and maintenance must only be executed under the observance of all

relevant safety measures. All the filters mentioned have to be disposed of

according to the respective legal terms.

Instruction manual

AS 300 CG

Seite 14

9 Circuit diagram

Instruction manual

AS 300 CG

Seite 15

10 Declaration of conformity

EU-Declaration of conformity

deconta GmbH

Im Geer 20

D-46419 Isselburg

Product: Waste water filtration unit Typ: 539

The design of the unit complies with EU- Machine directive 2006/42/EG

the following directives: EU- Low voltage directive 2006/95/EG

Applied harmonised standards: EN 292, EN 60335-1

Applied national standards: DIN VDE 0701, DIN VDE 0702

W.Weßling Isselburg, 22.10.2014

Other manuals for AS 300 CG

1

Table of contents

Other deconta Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Watts Premier

Watts Premier CT-1 Installation, operation and maintenance manual

BEGA

BEGA 116 Instructions for use

TeichTip

TeichTip SunSun HW-505A Operation manual

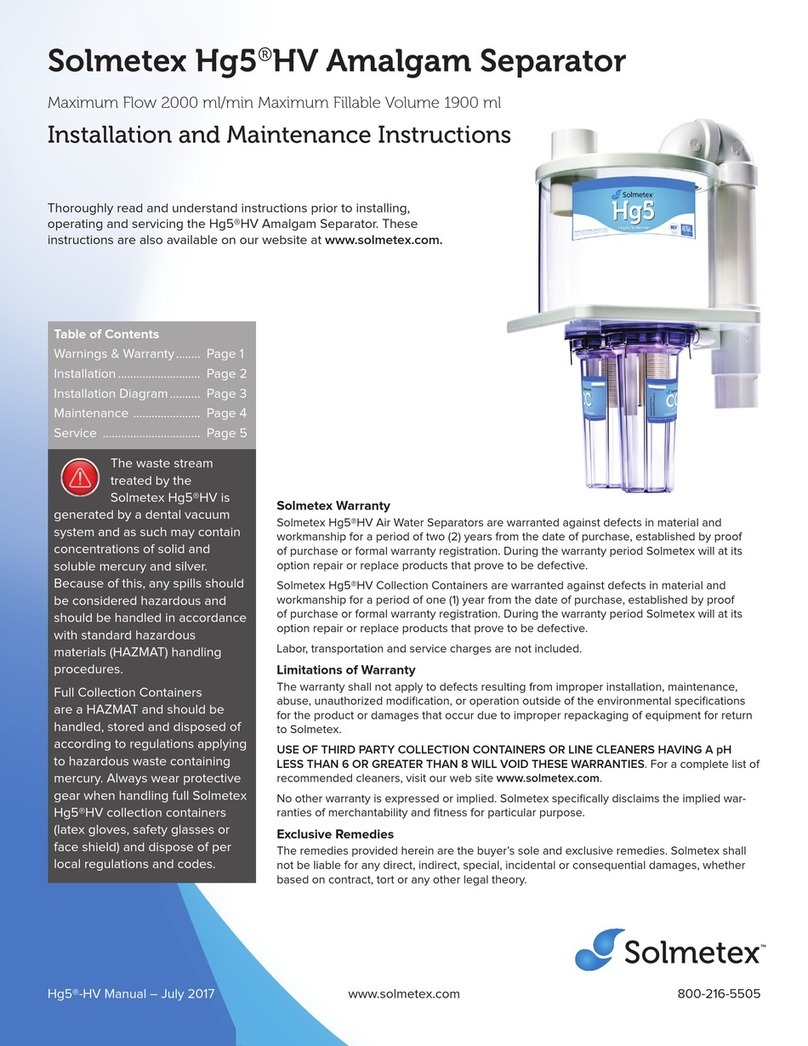

Solmetex

Solmetex Hg5 Installation and maintenance instructions

Ecosoft

Ecosoft FK1252CEMIXC instruction manual

DeWalt

DeWalt DXCM019-0352 quick start guide