Vertiv |NetSure™ Site Monitoring Unit Installation & User Manual (UM02440103)|Rev. A

TABLE OF CONTENTS

Admonishments Used in this Document............................................................5

Important Safety Instructions ..............................................................................6

Safety Admonishments Definitions.....................................................................................................6

General Safety .......................................................................................................................................................... 6

Handling Equipment Containing Static Sensitive Components............................. 6

Static Warning...........................................................................................................7

Introduction ...............................................................................................................9

Overview.........................................................................................................................................................................9

Specifications ..........................................................................................................................................................10

General Technical Specifications............................................................................................................... 10

Dimensions....................................................................................................................................................................... 10

Weight................................................................................................................................................................................... 10

Switch and Jumper Settings ................................................................................11

General............................................................................................................................................................................11

Switch Settings on SM-DUE......................................................................................................................11

Jumper Settings on SM-DUE.................................................................................................................. 12

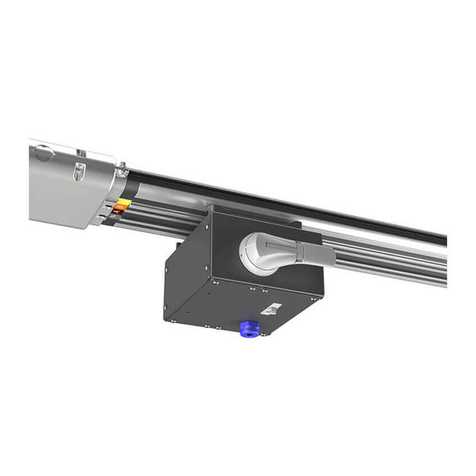

Installation................................................................................................................14

General Requirements....................................................................................................................................14

Installation Methods .........................................................................................................................................14

Electrical Connections ..........................................................................................16

Important Safety Instructions .................................................................................................................16

General...........................................................................................................................................................................16

Wiring Considerations.....................................................................................................................................16

SM-IO2 Frame Ground Connection...................................................................................................16

Customer Connections to SM-DUE..................................................................................................16

General................................................................................................................................................................................. 16

Input Power Voltage Connection............................................................................................................... 19

+5 VDC Power Supply Output Connection..................................................................................... 20

Ten (10) Monitoring Input Blocks Connections............................................................................21

CAN Bus Port Connection ................................................................................................................................25

Initially Starting, Configuring, and Checking SM-IO2 Operation ..............27

Initial Startup Preparation...........................................................................................................................27

Initially Starting the SM-IO2......................................................................................................................27

Configuring the SM-IO2................................................................................................................................27

Operation................................................................................................................. 28

SM-DUE Indicators ...........................................................................................................................................28

Programming .......................................................................................................................................................... 28

Troubleshooting and Repair............................................................................... 29

Important Safety Instructions ................................................................................................................29

Contact Information.........................................................................................................................................29

Troubleshooting ..................................................................................................................................................29