Apolix

Electronic and automatic polymerizer

Rev. 10/2019

Instruction for use

a.gree srl

Via Retrone 14, Altavilla Vicentina 36077 (VI) Italy

+39 0444 960 991 info@vertysystem.com

2/7

vertysystem.com

3. MODE OF USE AND CHARACTERISTICS

• Put the Furbo Alu Big/Small flask in the machine. Pour the necessary water in the tank (leaving at least a 2-cm gap to

the top)

• Close the lid until it latches. Start the process using the RUN/STOP button (17)

• The process can be stopped at any time using the RUN/STOP button (17)

• Once the process is started, it’s necessary to push the water release button (16). The LED will flash, and water and air

will be automatically released at the end of the process.

• In case of need, you can manually release the water by pushing and holding the water release button (16) for 5 se-

conds. The machine will automatically release the water.

• In case of extreme need, you can manually drain the water using the nozzle for water (6). This can only be done while

the machine isn’t running a program. Before emptying the water, push the RUN/STOP button (17).

• Once the machine has been emptied, you must press on the nozzle (6) again to close the electromagnetic valve.

IMPORTANT NOTES

• Before the first use of the day, it’s necessary to wet the orange gasket with a little water before closing the lid, to pro-

tect it from accidental damage.

• Once the pressure setting is memorized, it will stay so for all other programs as well

• Do not set the pressure at values exceeding 6 bars

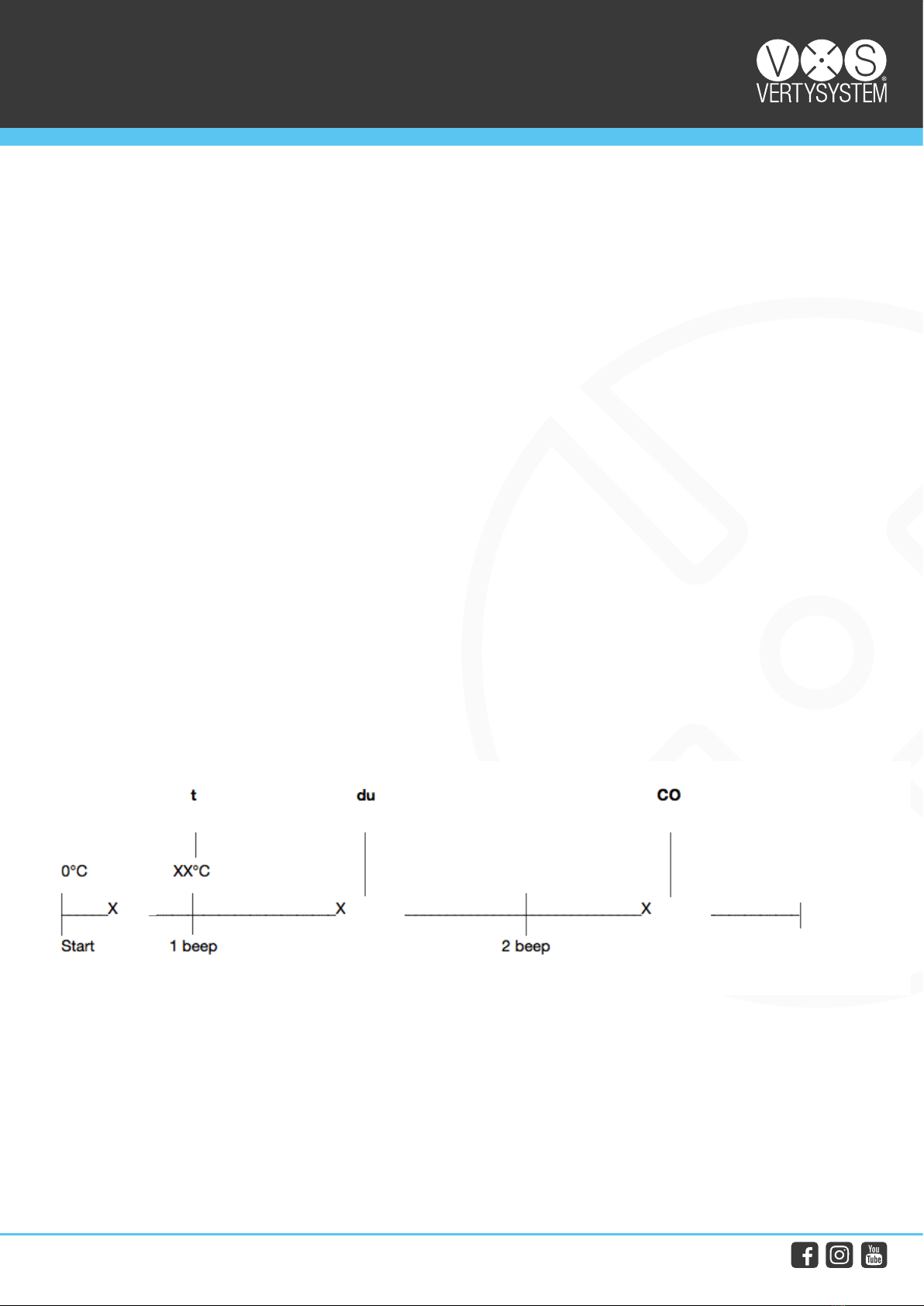

• If the dierence between the set temperature and the actual chamber temperature is below 10° C, it’s necessary to

hold the RUN/STOP button (2) for a few seconds to start a new cycle. The new cycle will start after an acoustic signal.

• Pressure will stay active until you manually release it. Do not open the machine lid until the temperature has gone be-

low 100°C, as to not risk burns with boiling water.

• The machine is engineered for use in places up to 2000 m above sea level

• Maximum air humidity has to be below 80% for temperatures up to 31°, and goes down to 50% for temperatures from

40° C.

• If the machine is used with accessories that were not provided by the manufacturer, safety is compromised.

4. SAFETY RULES

• The following precautions must be observed to avoid damages to personnel or to the machine:

• The machine musn’t be used by an operator who hasn’t read the instructions

• Before plugging the machine in, make sure that the grid tension is the same as the work tension. In case of dicrepancy,

consult a specialist

• Under no circumstance tamper with and/or modify the machine

• The stickers and warnings must be kept in legible conditions and must not be removed

• In case of damages the machine must not be activated, in order to protect the user or bystanders.

• Keep the power cord away from sources of heat, oils or damaging objects

• When moving the machine, do not hold it by the cord

• Do not use spare parts that don’t come from the manufacturer

• Prevent the machine from falling or receiving hits

• To function correctly, the machine has to be heated. Be mindful of the possible explosion hazard, or toxic/combustible

gas emission hazard that derive from heating

This symbol warns you that there is dangerously high tension

This symbols guarantees that the machine conforms to the Low Tension and

Electromagnetic Compatibility Directive, and related norms