Slide the complete KlickFix

Cartridge on to the pump shaft

Rotate cartridge so that

Position Control Pins,

and radial slots in

Deployment Sleeve,

are accessible for

future deployment of

more sealing lips.

Fit Cartridge on shaft. Allow access

to Positioning Clips and Radial Slots.

Montare la cartuccia sull'albero.

Lasciare accesso al posizionamento

delle clips ed alle scanalature radiali.

Encajar el cartucho en el eje. Permitir el

acceso a los clips de posicionamiento

y las ranuras radiales.

Installer le cartouche KlickFix sur

l'arbre. Libérer l'espace d'accès aux

clips et aux encoches radiales.

Bringen Sie die Kassette auf der

Welle an. Erlauben Sie den Eingang

der Positionier-Klammer und des

Radial-Slots.

Wees er zeker van dat er voldoende

ruimte beschikbaar is ten opzichte

van de eerste obstructie.

Re-assemble pump

Rimontare la pompa.

Wieder zusammenbauen der Pumpe.

Re-assemble the pump.

Do NOT force

the KlickFix

Cartridge into position

using hammer or sharp

tools

Installation Guide for

James Walker KlickFix®

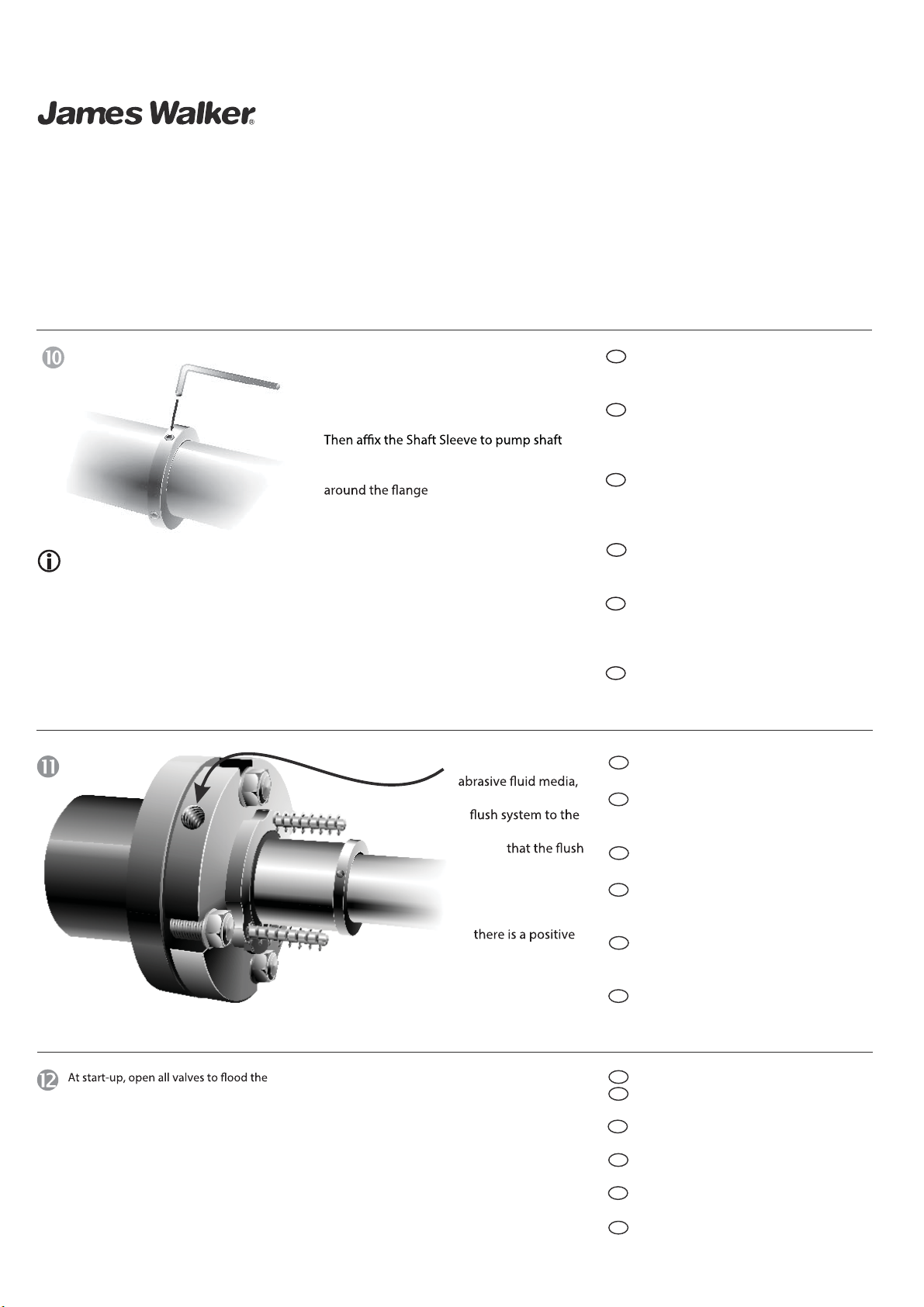

This operation is necessary only when a shaft sleeve

is being used.

If necessary, insert Shaft Sleeve (1).

Inserire, se necessario, il manicotto

dell'albero (1).

Indien nodig, plaats de asbus (1).

Si es necesario, inserte el casquillo

del eje (1).

Si nécessaire insérer le manchon

d'arbre.

Falls nötig, legen Sie die

Wellenschutzhülse ein (1).

Slide Shaft Sleeve into the KlickFix

Cartridge from its outboard end, until

the bevelled end protrudes through the

end of the KlickFix cartridge.

EN

DE

IT

NL

ES

EN

DE

IT

NL

ES

EN

DE

IT

NL

ES

Zet de pomp weer in elkaar.

IVolver a montar la bomba.

Assembler à nouveau la pompe

F

F

F

placing the gland gasket

over the seal housing and

against the gland plate.

Slide Cartridge to housing flange.

Affix housing bolts.

Far scorrere la cartuccia fino alla

flangia della sede. Fissare i bulloni

della sede.

Schuif de Klickflix naar de sealkamer.

Monteer de bevestigingsbouten.

Deslizar el cartucho hasta la brida

del alojamiento. Apretar lso

tornillos del alojamiento.casquillo.

Glisser le cartouche KlickFix dans

le corps de pompe. Positionner,

puis serrer les boulons de fixation

Schieben Sie die Kassette in den

Gehäuseflansch. Befestigen Sie die

Gehäuseschrauben.

Slide the KlickFix Cartridge to the

machined face of the seal chamber

/gland housing. Ensure that the

Assemble the holding

only. Then tighten the

nuts/bolts using good

engineering practice.

EN

DE

IT

NL

ES

Gland bolts must be tightened equally to

prevent seal misalignment. Ensure that the

shaft turns freely. F