TFP1640

Page 4 of 4

NATIONAL FIRE PROTECTION ASSOCIATION and NFPA are registered trademarks of National Fire Protection Association;

MONEL is a registered trademark of Special Metals Corporation

1400 Pennbrook Parkway, Lansdale, PA 19446 | Telephone +1-215-362-0700

© 2021 Johnson Controls. All rights reserved. All specifications and other information shown were current as of document revision date and are subject to change without notice.

Care and

Maintenance

The following procedure and inspec-

tions must be performed as indicated,

in addition to any specific requirements

of the NFPA� Any impairment must be

immediately corrected�

Before closing a fire protection system

main control valve for maintenance

work on the fire protection system

that it controls, obtain permission to

shut down the affected fire protection

system from the proper authorities

and notify all personnel who may be

affected by this action�

The owner is responsible for the inspec-

tion, testing, and maintenance of their

fire protection system and devices in

compliance with this document, as well

as with the applicable standards of the

NATIONAL FIRE PROTECTION ASSO-

CIATION (e�g�, NFPA 25), in addition to

the standards of any other authorities

having jurisdiction� Contact the install-

ing contractor or product manufacturer

with any questions�

Automatic sprinkler systems should be

inspected, tested, and maintained by a

qualified Inspection Service in accor-

dance with local requirements and/or

national code�

Maintenance Procedure

It is recommended that Model A strain-

ers be flushed at least annually� More

frequent flushing may be necessary

where water supplies are non-potable

and/or contain debris which could clog

1/3 or more of the basket open area�

Note: Never disassemble or remove

any strainer component without veri-

fying that the system is depressurized

and drained.

Strainers should be thoroughly flushed

clean after each system operation or

flow test and during routine inspections

as follows:

Step 1. Open flushing connection

valve (Ref� Design Criteria) allowing

flow until drain water runs clear� Close

valve�

Note: If heavy sediment in drain water

persists or there are indications that

all debris such as large stones may

not have been removed, basket must

be removed for cleaning; Proceed to

Step 2.

Step 2. Shut down and drain system�

Step 3. Remove end closure nuts and

bolts, flange and ring gasket�

Step 4. Withdraw basket in slow, hori-

zontal motion to minimize possibility of

debris falling from open inlet end into

body�

Step 5. Empty debris from basket and

clean body interior�

Step 6. Insert basket into body until

open inlet end is fully seated against

inlet connection flange�

Step 7. Install end closure gasket,

flange, and nuts and bolts� Gradually

tighten all nuts and bolts in cross-draw

sequence to apply uniform load around

flange�

Step 8. Ensure flushing connection

valve is closed�

Limited

Warranty

For warranty terms and conditions, visit

www�tyco-fire�com�

Ordering

Procedure

Contact your local distributor for avail-

ability� When placing an order, indi-

cate the full product name, including

description and part number (P/N)�

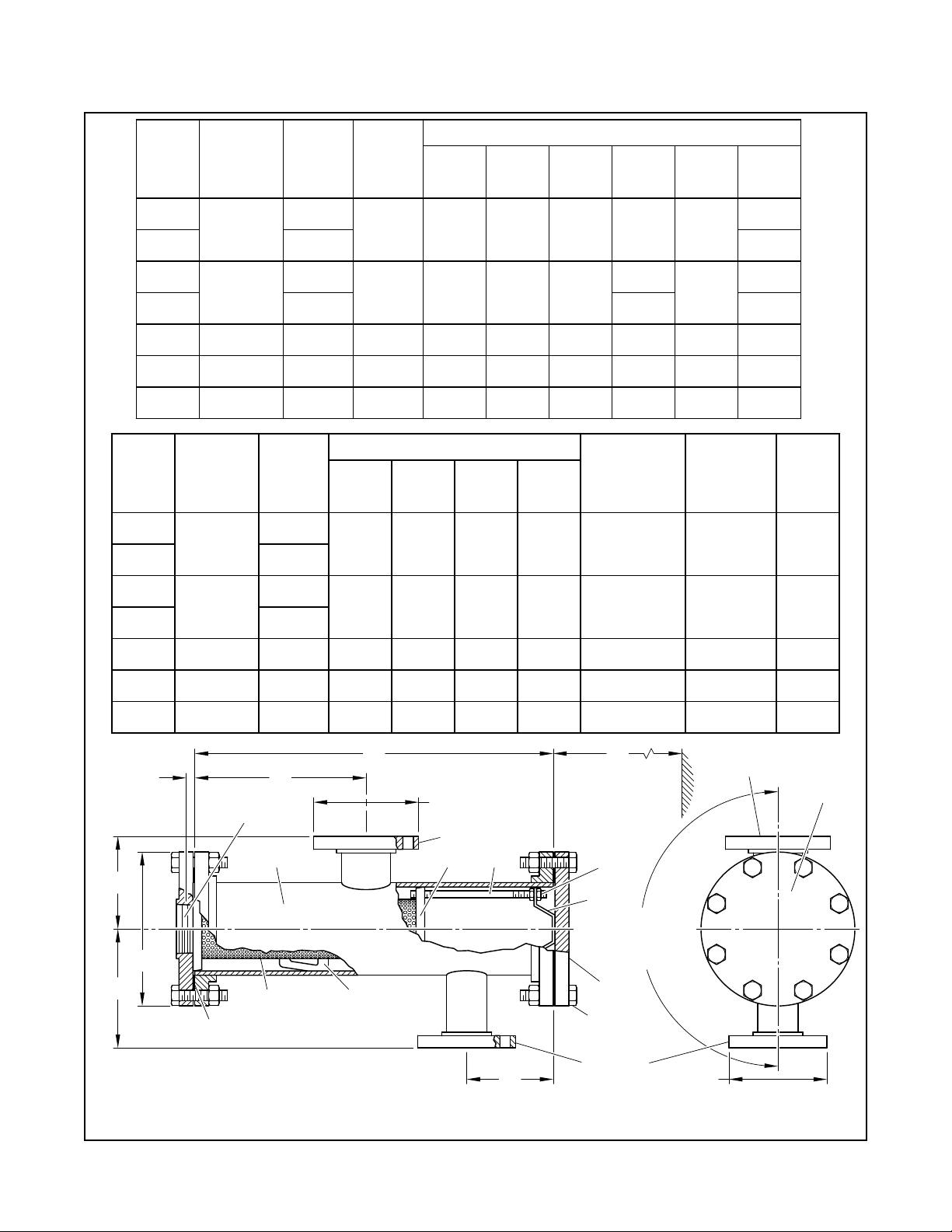

Standard Order Strainers

Specify: Standard Model A Pipe Line

Strainer, (specify) Inlet Size, Figure No�

(specify), P/N (specify):

1260-2 ����������������������52-270-1-011

1260-3 ����������������������52-270-1-013

1260-5 ����������������������52-270-1-015

1260-6 ����������������������52-270-1-016

1260-7 ����������������������52-270-1-017

Note: Standard order strainer features

inlet and outlet connections equal in

size, stainless steel basket assembly,

and outlet connection located at Angle

"J" 180° from flushing connection (Ref.

Figure 1). Adjusted outlet connection

available on request, refer to Special

Order Strainers.

Special Order Strainers

Specify: Standard Model A Pipe Line

Strainer, Figure No� (specify), (specify

Stainless Steel or MONEL) Basket

Assembly, (specify) Inlet Size, (specify)

Outlet Size, Outlet Angle "J" (specify

degrees)

Notes: Special order strainer features

any of the following: MONEL basket

assembly; inlet and outlet connec-

tions differing in size; outlet connec-

tion oriented at angle other than the

standard 180° Angle "J" (90° to 270°

counter-clockwise from flushing con-

nection when viewing strainer from end

closure). Ref. Figure 1.

It is recommended that orders for

strainers with special outlet locations

or angles be accompanied by sketches.

Part numbers are not specified for

special order strainers.

Replacement Parts

Specify: (specify inlet size) Model A

Strainer (specify part description),

P/N (specify):

Stainless Steel Basket Assembly

3 Inch �����������������������92-270-1-211

4 Inch �����������������������92-270-1-213

6 Inch �����������������������92-270-1-215

8 Inch �����������������������92-270-1-216

10 Inch ����������������������92-270-1-217

MONEL Basket Assembly

3 Inch �����������������������92-370-3-211

4 Inch �����������������������92-370-3-213

6 Inch �����������������������92-370-3-215

8 Inch �����������������������92-370-3-216

10 Inch ����������������������92-370-3-217

Ring Gasket

3 Inch �����������������������92-370-1-015

4 Inch �����������������������92-370-1-016

6 & 8 Inch ��������������������92-370 -1- 018

10 Inch ����������������������92-370 -1- 020

Note: Ring gaskets are identified per

strainer inlet size. Actual gasket sizes

vary per Body Nominal Pipe Sizes given

in Figure 1.