Table of Contents

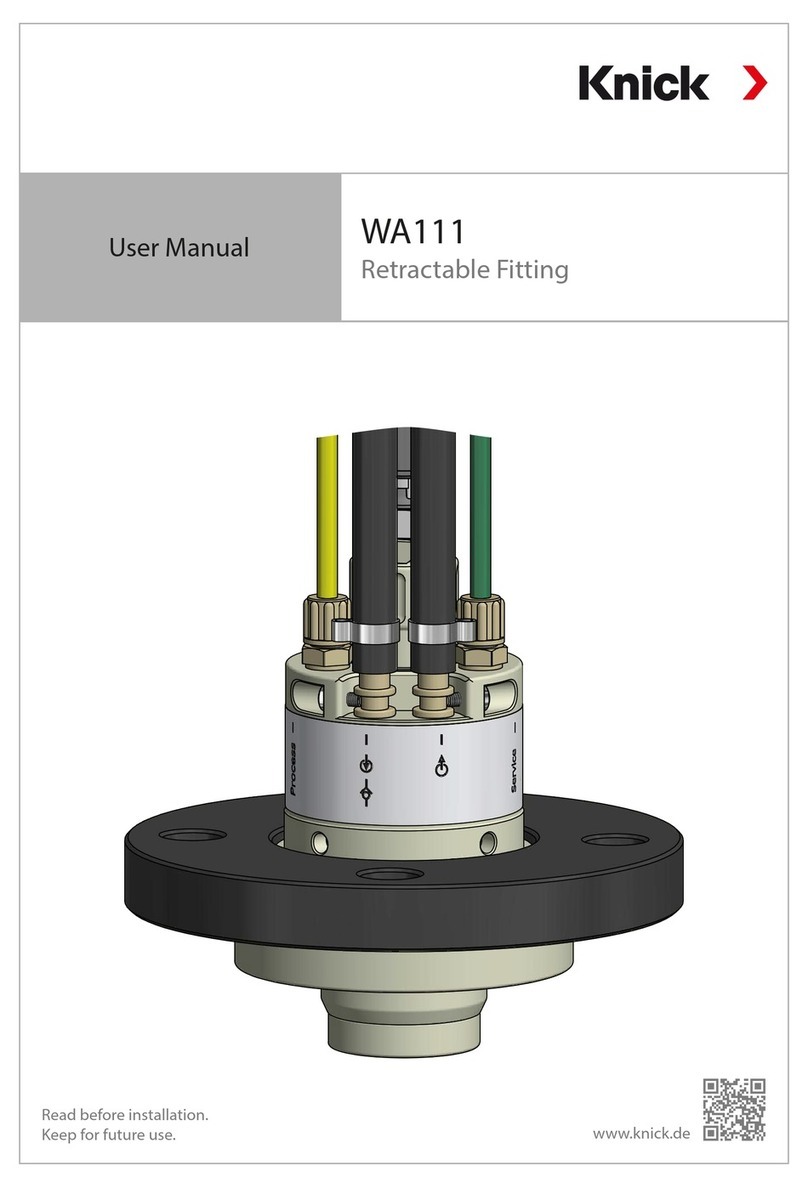

SensoGate WA 132

Safety Instructions ........................................................................................................................... 3

Intended Use..................................................................................................................................... 5

Symbols and Markings.................................................................................................................................................................. 5

Rating Plates ..................................................................................................................................................................................... 6

Package Contents ........................................................................................................................................................................... 6

SensoGate WA 132 Product Coding................................................................................................7

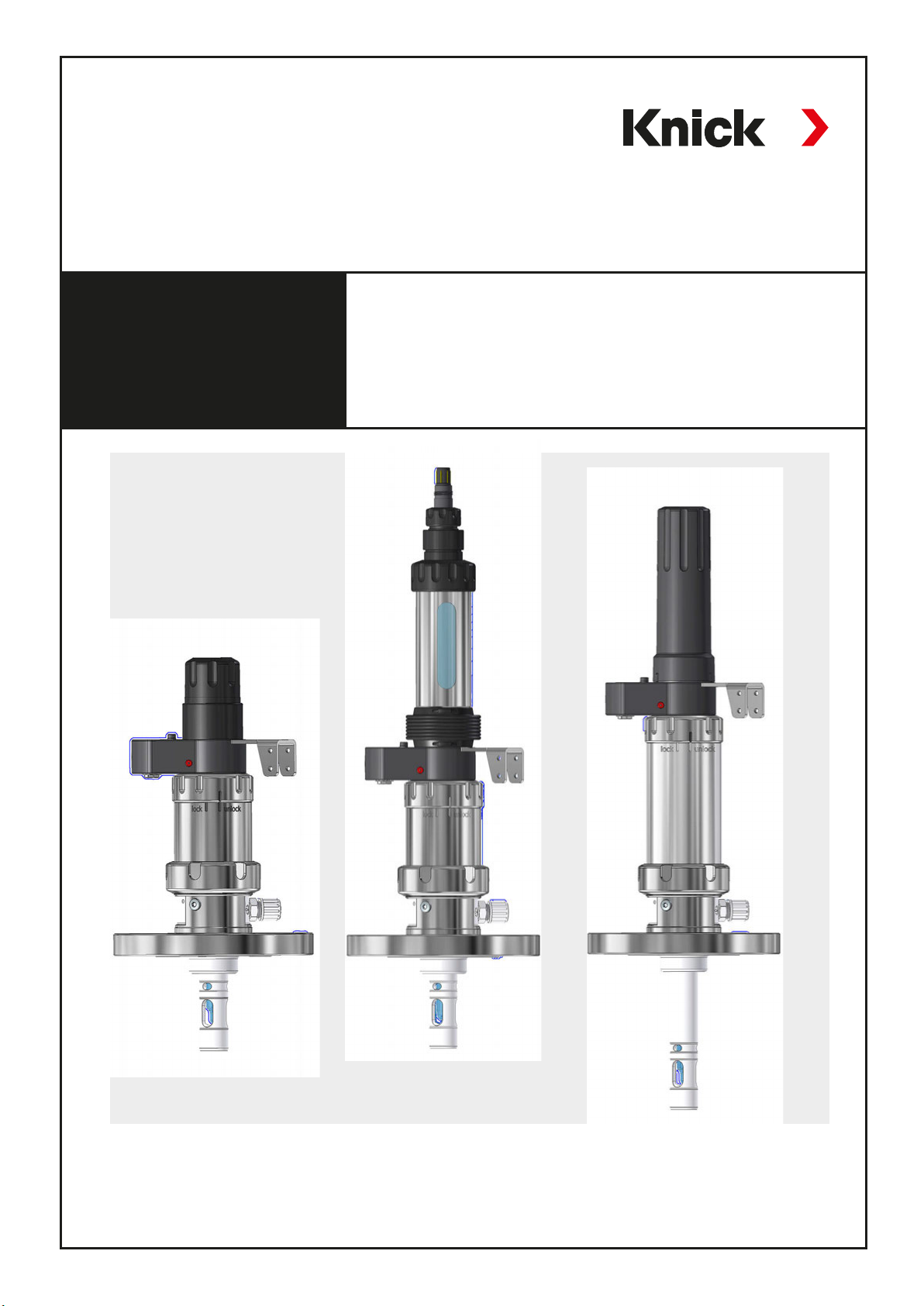

Function Description........................................................................................................................ 8

Overview of Retractable Fitting......................................................................................................9

Modular Design: Drive Unit, Immersion Tube, Process Adaptation...........................................................................10

SensoLock .......................................................................................................................................11

Media Connection ..........................................................................................................................12

Installing the Media Connection.............................................................................................................................................12

SERVICE Position ............................................................................................................................13

PROCESS Position...........................................................................................................................14

Installing and Removing a Sensor ................................................................................................15

Sensors with Solid Electrolyte.......................................................................................................16

Short Immersion Depth..............................................................................................................................................................16

Installing the Sensor ................................................................................................................................................................16

Removing the Sensor..............................................................................................................................................................18

Long Immersion Depth...............................................................................................................................................................19

Installing the Sensor ................................................................................................................................................................19

Removing the Sensor..............................................................................................................................................................21

Sensors with Liquid Electrolyte.....................................................................................................23

Installing the Sensor ................................................................................................................................................................23

Removing the Sensor..............................................................................................................................................................24

Drive Unit ........................................................................................................................................25

Removing the Drive Unit .......................................................................................................................................................25

Installing the Drive Unit .........................................................................................................................................................26

Immersion Tube ..............................................................................................................................27

Replacing the Immersion Tube............................................................................................................................................27

Removing the Immersion Tube...........................................................................................................................................28

Installing the Immersion Tube .............................................................................................................................................29

Calibration Chamber......................................................................................................................30

Removing the Calibration Chamber..................................................................................................................................30

Installing the Calibration Chamber....................................................................................................................................31

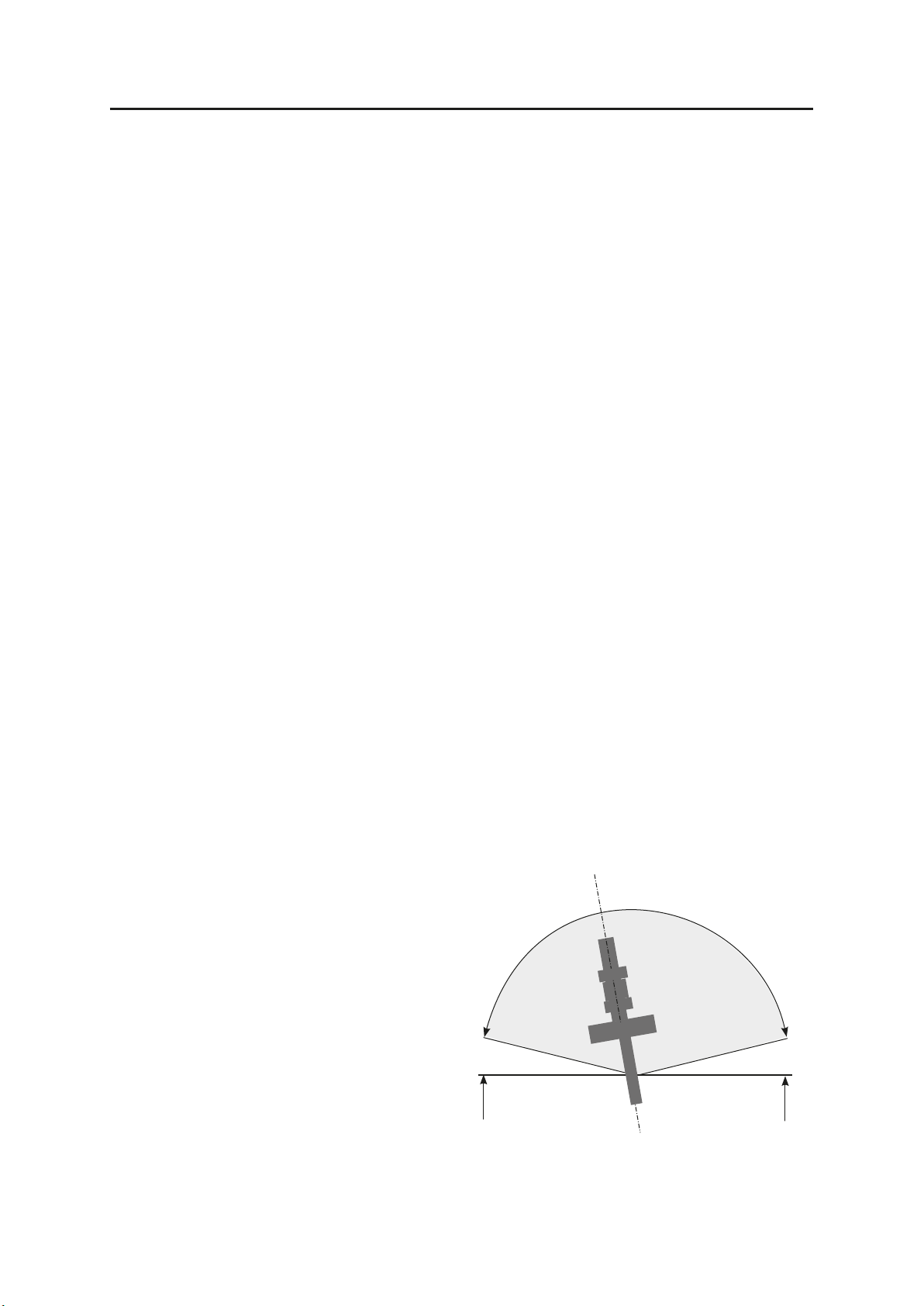

Installation Dimensions.................................................................................................................32

Specifications..................................................................................................................................36

Maintenance ...................................................................................................................................37

Maintenance Intervals.................................................................................................................................................................37

Servicing the Immersion Tube .................................................................................................................................................37

Servicing the Drive Unit .............................................................................................................................................................38

Lubricants, O-Rings ......................................................................................................................................................................38

Sealing Kits for Maintenance and Servicing .......................................................................................................................39

Accessories / Spare Parts ...............................................................................................................40

Declaration of Contamination.......................................................................................................42

Index................................................................................................................................................43

2