We reserve the right to make technical modifications.

Rittal busbar machining, mobile CW 120-M

6

Available accessories

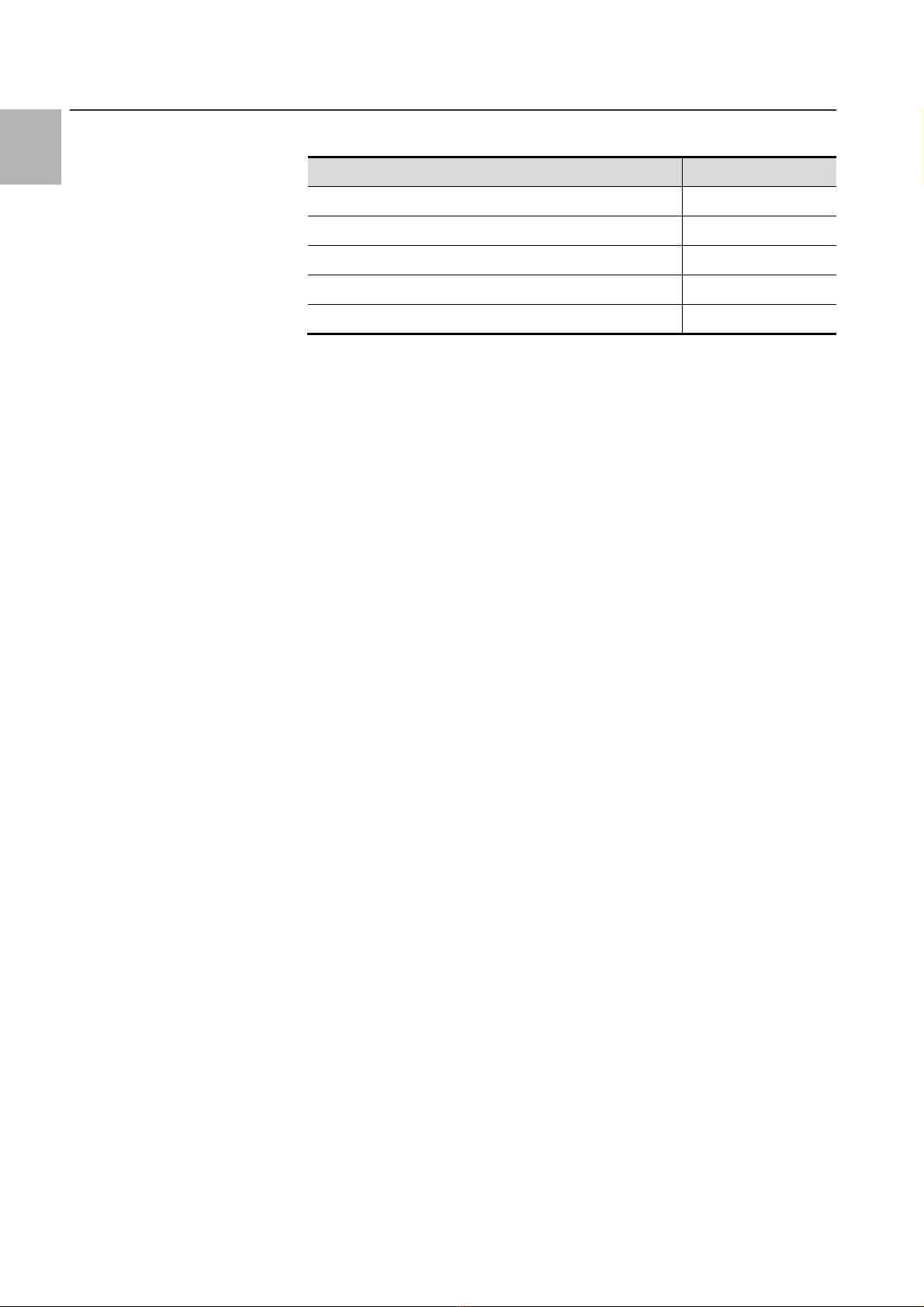

Available accessories Model No.

Hydraulic cylinder 4055.806

Hydraulic hose (3 m) 4055.807

Male die, round 4055.740 – 4055.750

Female dies, round 4055.770 – 4055.780

Male and female dies for slots and special accessories 4055.791

Tab. 3: Available accessories

7

Unit description

The "Busbar machining, mobile" CW 120-M is a multifunctional work station

equipped with multiple single-acting hydraulic cylinders for the bending, hole

punching and cutting of busbars. The hydraulic pressure is produced by an in-

tegrated radial piston pump. The pump produces with maximum pressure of

700 bar a work force of approximately 23 tons.

The single-pedal safety foot-operated switch is connected to the "Busbar ma-

chining, mobile" via a socket (fig. 1, 4). Four push-buttons (fig. 1, 8, 12, 13 and

fig. 2, 19) serve to select the desired machining station. Machining is possible on

only one station. The cutting unit (fig. 1, 15) for shortening busbars as well as the

bending and hole-punching unit (fig. 1, 16) are surrounded by a stable, abrasion-

resistant table top (fig. 1, 1) made of stainless steel. The table top has an inte-

grated limit stop that can be extended to 1200 mm (fig. 2, 26) for use by all work

stations.

An additional hydraulic connection (fig. 1, 5) permits the connection of external

hydraulic units to augment the existing work stations. To simplify the machining

of long workpieces, the "Busbar machining, mobile" is equipped with an extend-

ible support roller (fig. 1,7).

Two emergency stop switches (fig. 1, 14 and fig. 2, 18) can stop the hydraulic

pump immediately in dangerous situations and allow the tool to be returned to

its initial position. The deployment of a frequency converter allows the travel

speed of the tools to be set using a potentiometer (fig. 1, 10). During hole cutting

and punching, the main body is protected with a stable safety protection hood

(fig. 1, 17). The height of the main body can be adjusted easily with a rotary knob

(fig. 1, 9) in accordance with the display for the height setting. Four lockable,

large drawers (fig. 1, 2) offer sufficient storage space for the deployed tools and

work aids. A collection vessel for copper scraps is located behind the door (fig. 2,

21) next to the electric switch cabinet (fig. 2, 22). The mains cable (fig. 2, 23) is

embedded in the side panel of the "Busbar machining, mobile" and, when re-

quired, can be extended to the maximum length of 4.5 m or rolled in completely.

EN