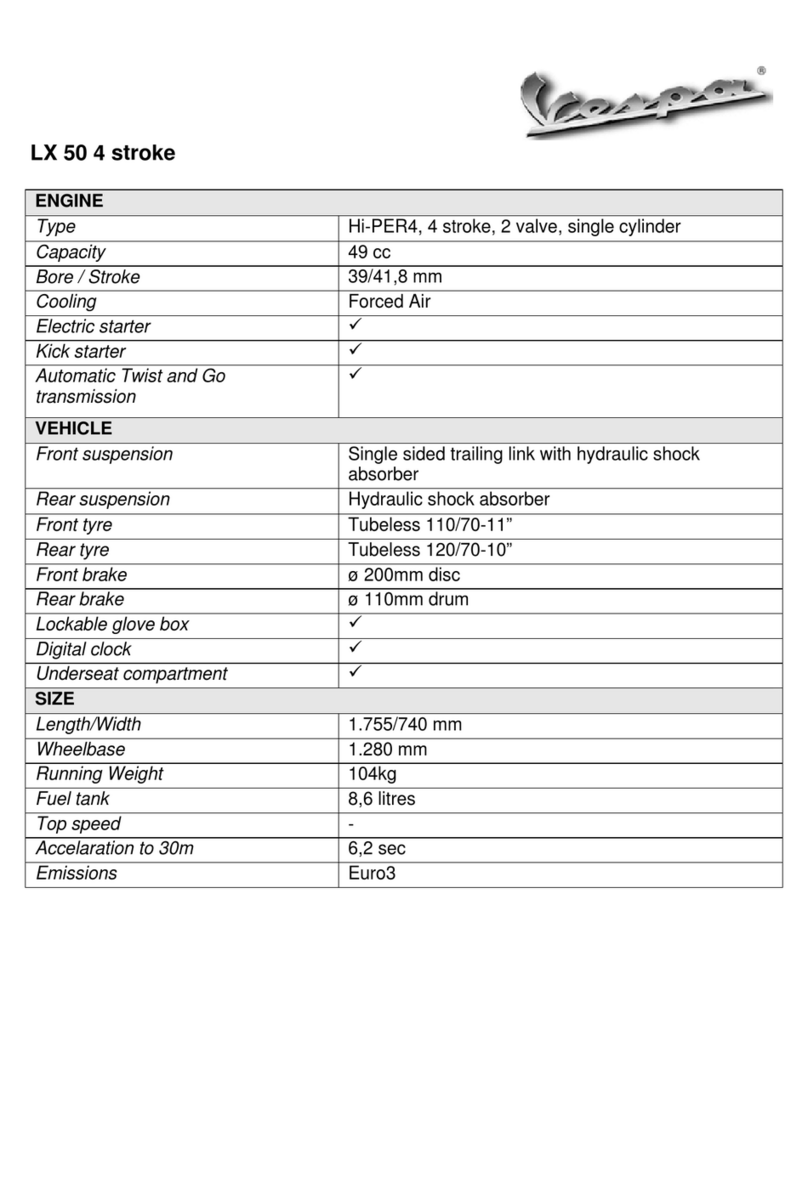

ENGINE

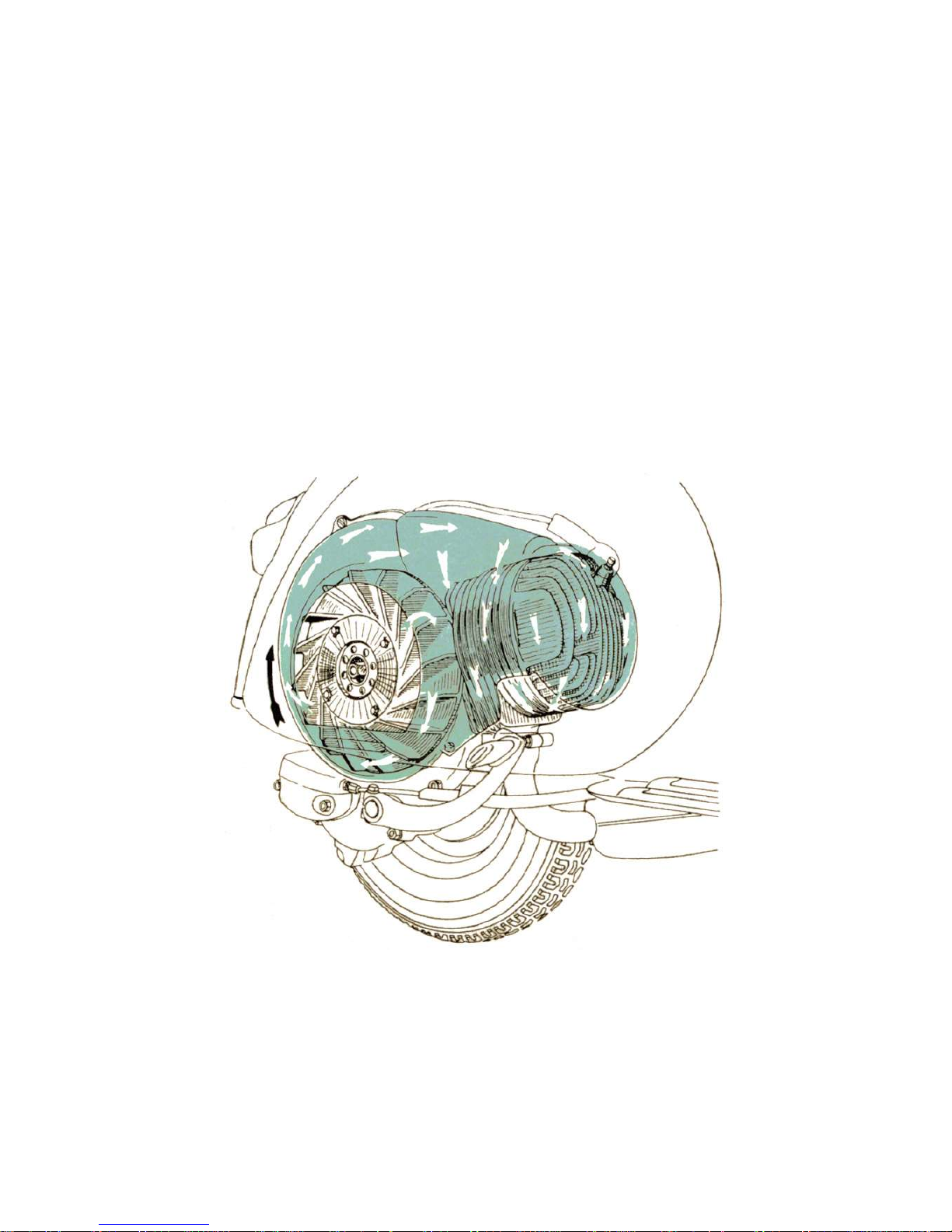

Single horizontal cylinder, two-stroke, with deflector iston and rotary valve, i. e.: fuel

mixture flow to the cylinder is controlled by the rotation of a crankweb (see Fig. 4).

The engine works on a 2% gasoline-oil mixture.

Bore 57 mm (2.24")

Stroke 57 mm (2.24")

Dis lacement 145.45 cc ( 8.88 cu.in )

Com ression ratio 6.8 to 1 .

The engine is ivoted to the chassis of scooter through the cylindrical arm of the

crankcase half, clutch side, rovided with a s indle and two bushes (see Fig. 4). Its

vibrations are dam ed by the rear sus ension with variable rate coil s ring and hydraulic

dam er (see also age 13 ). The rear wheel is secured to the end of the mainshaft.

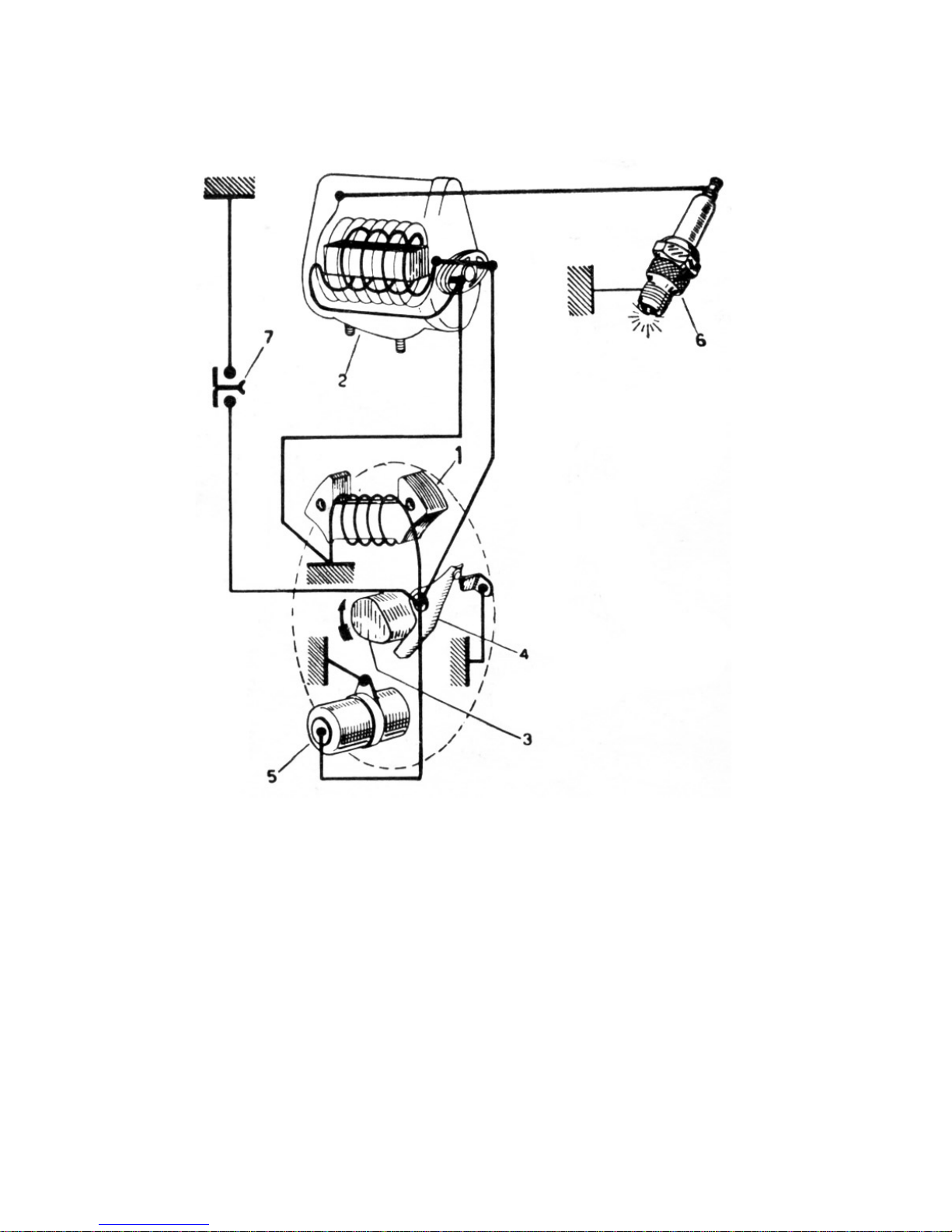

Ignition by an external H. T. coil with rimary winding fed by another coil inside the

flywheel magneto (see Fig. 5).

Sparkplug: Marelli CW 230 A - T or CW 225 N - T, AC 43 F, Cham ion L. 86, Bosch W

225 T 1. - KLG F 70 or F 75.

Ignition timing with s ark advance of 28° ± 10.

Lubrication of iston, cylinder, wrist in, connecting rod, crankshaft, main bearings is

attended to by the oil in the fuel mixture.

Both clutch and gear box o erate in oil bath.

Fuel supply by gravity with gasoline-oil mixture. The carburettor is embodied in the air

cleaner case, has a late-sha ed slide valve and immersed jets.

Fuel tank with total ca acity of 7.7 liters (2.03 USA gals; 1.7 im . gals) and emergency

reserve of about 1.4 I (0.37 USA gals; 0.3 im . gals).

Three way ta («off» - «on» - «reserve»).

Transmission. The engine (see Fig. 4) directly drives the rear wheel through clutch, cush

drive and gear box.

Engine to wheel transmission ratios:

First : 13.35 to 1

Second : 9.32 to 1

Third : 6.64 to 1

Fourth : 4.73 to 1