© Vestamatic GmbH Subject to modifications!

- 5 -

-Nr.: 84500601 K1• Vestamatic GmbH • Dohrweg 27 • D-41066 Mönchengladbach • www.vestamatic.com

Safety precautions / Explanation of warning signals

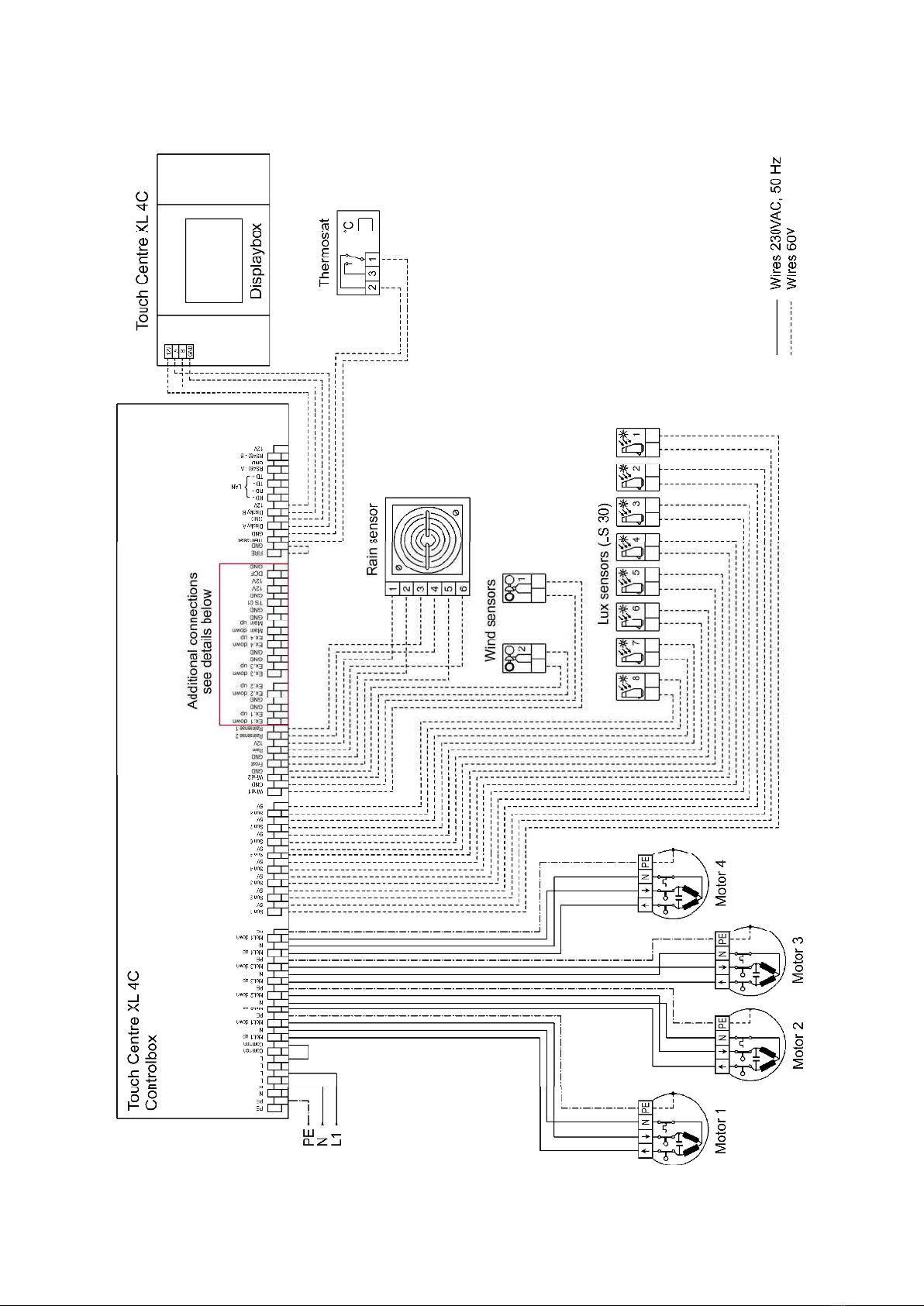

– Contact a professional electrician to install the control system, because the control

system requires a power supply of 230VAC, 50 Hz.

– Check the control system for signs of mechanical damage after unpacking. If you notice

any shipping damage, do not start up the control system and notify your supplier

immediately.

– The control should only be used for the purpose specified by the manufacturer (refer to

the operating instructions). Any changes or modifications thereof are not permissible

and will result in loss of all warranty claims.

– If it is no longer possible to guarantee the safe operation of the control or the connected

devices, you should turn the control off immediately and make sure that it cannot be

operated unintentionally.

– Before carrying out work on sunshading devices or skylights which are operated by the

control, you must switch off the control box power supply.

– For safety reasons, if there is no rain or frost sensor connected to the control you are

advised, depending on the sunshade design, to set the control to manual operation if the

temperature drops below +1

°C. This will prevent the sunshade from extending automati-

cally (e.g. due to the sun).

– This device contains a pollutant battery. The end user must recycle all used batteries in

accordance with regulation 91/157/EWG). Disposing of the batteries in household waste

is strictly forbidden.

– The use of a power pack other than the optional power pack supplied by the control’s

manufacturer may limit the functions available and/or damage the control. Such use is

therefore not permitted.

– In the event of a power failure, the control and all connected devices will no longer be

operable.

– For safety reasons, if a severe weather warning is issued, retract all connected devices

and change the operating mode of all groups to manual operation mode.

Ä

Danger

There is an imminent danger to the life and health of personnel. Any failure to follow the

hazard warnings will immediately put personnel at risk.

Ä

Warning

There is a potential danger to the life and health of personnel.

Ä

Caution

A situation which has an undesirable consequence. The extent of health damage is

small. Example: foreseeable operating errors.

Ä

Attention

Material damage to the device may result if the hazard warnings are not followed.

I

Failure to comply will result in product handling faults, but not in damage to property or

personal injury.

h Application advice and useful information on how to make best use of the product.