Subject to modifications.© Vestamatic GmbH

Art.-Nr.: 3060 002 DE 0319 A03 • Vestamatic GmbH • Dohrweg 27 • D-41066 Mönchengladbach • www.vestamatic.de

3/4

G

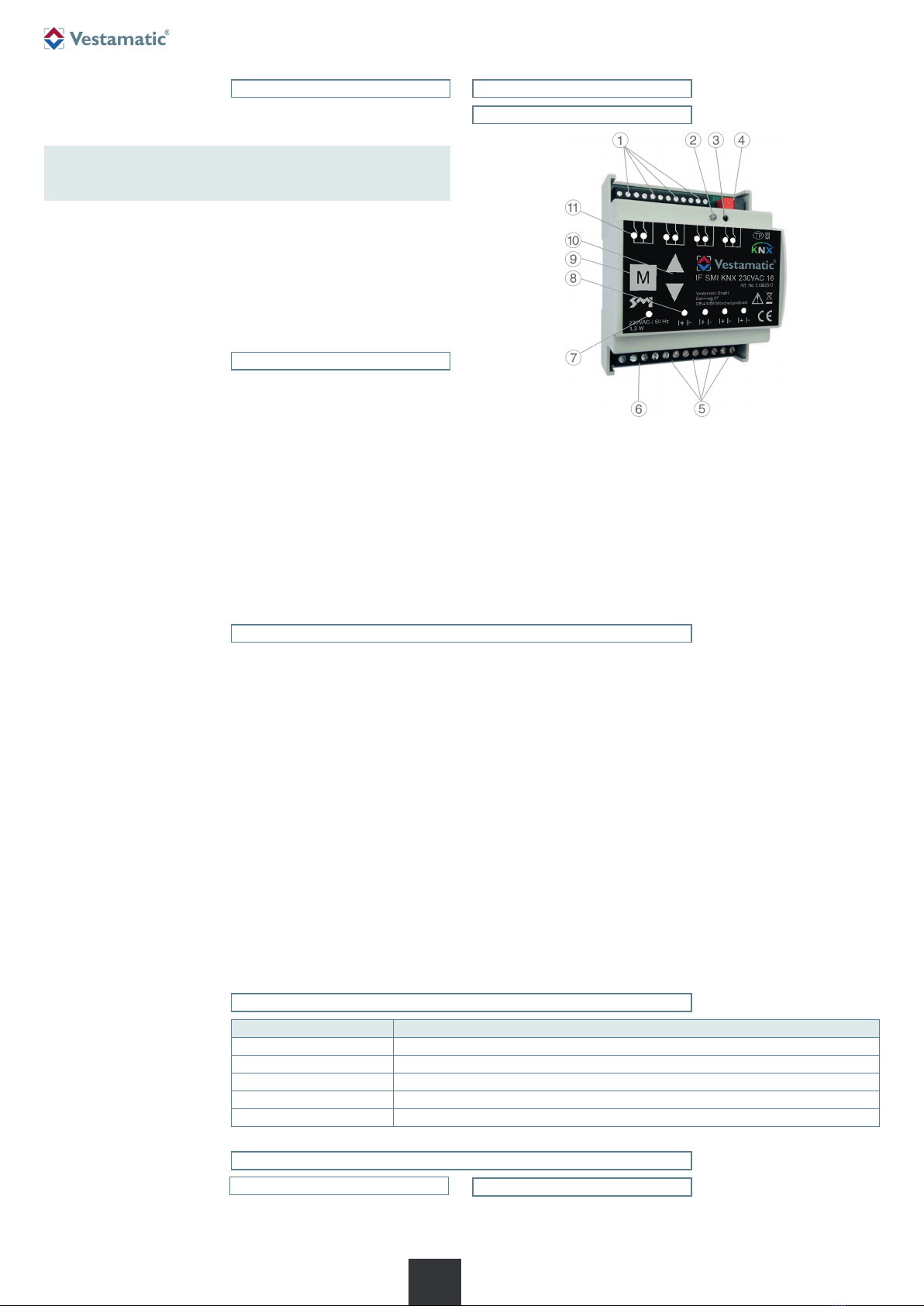

6.2. Control and display elements

Test buttons UP / DOWN

– To control the motor outputs in test mode.

– Short key press (< 0.4 s) > step / stop.

– Long key press (> 0.4 s) > movement command end position.

– Additionally the test buttons UP/DOWN can be used to re-learn the motor

addressing (for further information see chapter 8., “Troubleshooting”.

Status display motor output

– LED is off = channel is in normal-/automatic mode.

– LED flashes “GREEN” = automatic lock is active

(for further information see software-helpfile).

– LED lights continuously “GREEN” = channel is in test mode, control

via test buttons is activated.

– LED flashes “RED” = security lock is active

(for further information see software-helpfile).

– LED lights continuously “RED” > SMI motor output error

(for ruther information see chapter 8., “Troubleshooting”).

Status display local operation

– The corresponding LED (UP / DOWN) lights “GREEN” as long as the

button of the local operation is pressed.

Status display ready for operation

– Lights continuously “GREEN” when the device is ready for operation.

Programming button

– Activates/deactivates the programming mode

(supply voltage and KNX bus voltage must be available).

Programming LED

– Lights continuously “RED” when the programming mode is activated.

Test button “M”

– Used to select a motor output for direct operation via the test buttons

UP/DOWN (test mode).

If a motor output is in test mode, the corresponding status LED lights

continuously “GREEN”.

– By briefly pressing the “M” button all 4 channels are switched to the

test mode.

– Each additional operation switches through the individual channels

1, 2, 3 and 4.

– After 6 operations all channels are in normal mode again.

– Additionally the “M” button can be used to reset the device (for further

information see chapter 8., “Troubleshooting”).

5.2 Configuration

– The configuration of the motor control unit is done via ETS from version

4.0 of KNX-Association.

5.3 Commissioning / Test run

For commissioning of the motor control unit proceed as follows:

– Check the condition of the device and the tight attachment of the terminals

and connections.

– Switch on the supply voltage.

– Check supply voltage and status display on the device.

– Check function of the SMI drives by means of test buttons – if communi-

cation to the SMI drives is not possible, check SMI wiring.

– Check the local operation –

if the function is reversed, correct the local operation connection.

– Move blinds, awnings, large louvre blades, roller shutters, windows, light

domes, etc. into a safe end position.

– Mount all protective covers.

– Maintain system documentation and, if necessary, affix labels and/or

signs.

7. Operation

Automatic operation is performed according to the parameters specified

in the ETS configuration. The control command received via the KNX bus

are considered.

The manual operation is done via the local operation inputs of the motor

control unit by means of push buttons or switches (see chapter 6.3, „Local

operation“) and/or via the KNX system (see software-helpfile).

7.1 Manual operation 7.2 Automatic operation

Requirements

– Supply voltage and KNX bus voltage must be present.

Approach

– Connect PC / Laptop to the KNX bus via programming interface.

– Set the motor control unit to programming mode by pushing the pro-

gramming button, the programming LED lights continuously “RED”.

– Download the physical address and the application program.

NOTE!

For details about the configuration software see documentation

of KNX-Association.

I

6. Design and function

1. Push button local operation-

(UP/DOWN/+)

2. Programming LED

3. Programming button

4. KNX bus connector

5. Motor connection terminals

6. Connection terminal supply

voltage

7. Status display ready for

operation

8. Status display motor output

9. Test button “M”

10. Test buttons (UP/DOWN)

11. Status display local operation

6.1 Complete overview

Location of control and display elements

6.3. Local operation

The local operation can be in-

stalled as push button or switch.

If no adjustments have been

made in the ETS configuration,

the functionality is according to

the table beside:

Function Control

“Upper end positon”

long key press “UP” (> 0.4s)

“Lower end position”

long key press “DOWN” (> 0.4s)

“Shading position”

long key press “DOWN” (> 0.4s), immediately followed by short key press “DOWN” (<0.4s)

“STOP”

short key press in opposite direction of current movement (<0.4s)

“Move slats”

short key press when stationary (<0.4s)