Rev. 5/8/2015 WTJ-HITCH, MANUAL

Copyright 2015 Vestil Manufacturing Co. Page 8of 10

Proper loading:

Before using the crane, prepare the vehicle. Park the vehicle on level ground and engage the parking brake. If

you will use the crane on a pickup truck, it might be necessary to lower or remove the tailgate to accommodate

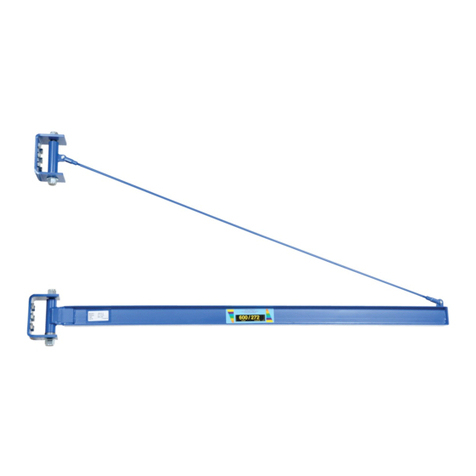

the load. Recall that the boom brace can be attached to the boom at either of 2 positions (see Step 5 on p. 6).

Attaching the brace to position 1 will allow you to raise loads as high as possible. Attachment to position 2

optimizes boom reach (horizontal distance) but does not allow loads to be lifted as high. Select the appropriate

attachment point for the brace and then proceed to the next step.

Next, bring the load to the vehicle. Rotate the boom away from the vehicle and position the load directly below

the load hook. Attach necessary rigging to the load; then attach the load hook to the rigging.

Slowly raise the load off of the ground with the winch. Observe both the crane and the load as the load rises.

Make sure that the load does not swing, because the post will tilt slightly under the weight of a load. Observe the

crane post and make sure that it is substantially vertical while the load is applied. When the load is adequately

elevated, slowly push the load into the vehicle and lower it until it is fully supported by the vehicle. Next,

disconnect the load hook from the rigging and turn the winch until the hook is fully retracted.

Do not drive while the crane is attached to the vehicle. Either disconnect the entire crane assembly by pulling

the hitch tube out of the receiver or remove the 9in. bolt (9) that fastens the upper assembly (post, boom, and

brace) to the base frame.

Lowering the tailgate:

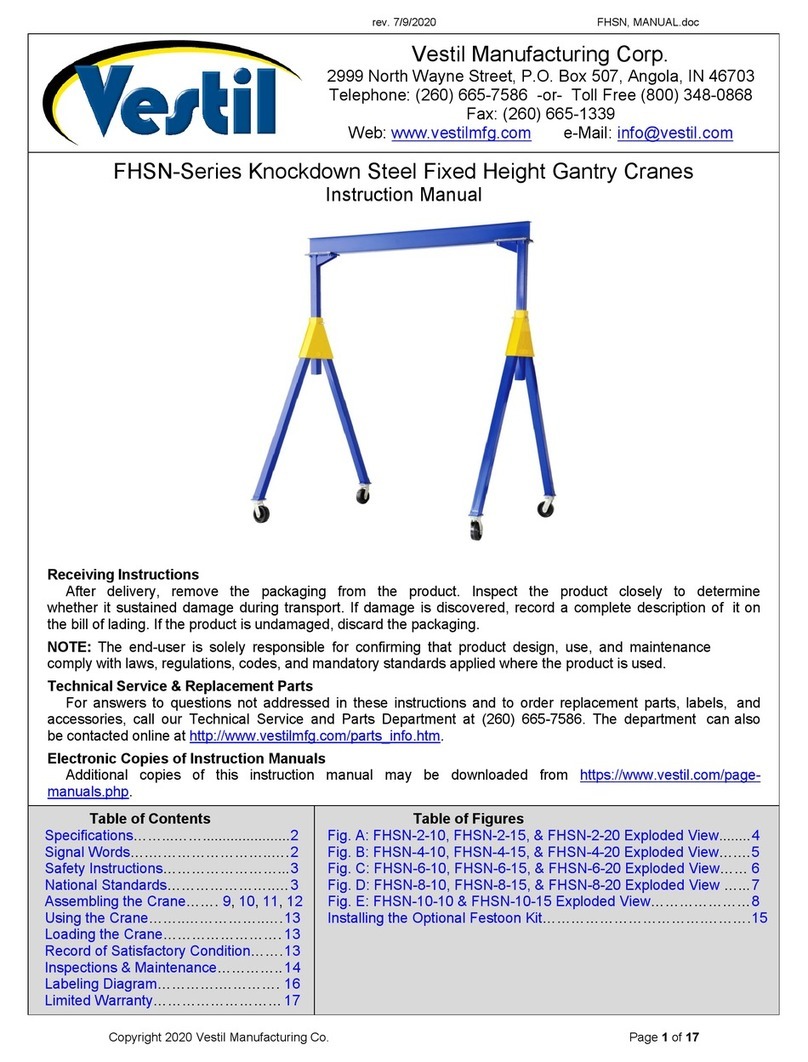

The tailgate of some trucks cannot be lowered without contacting

the boom brace. The crane is designed to address this issue without

having to disconnect hardware. First, retract the load cable. Then,

grasp the bottom of the boom brace and lift it off of the supporting

bolt. The bottom of the brace is slotted to facilitate quick

disengagement from the bolt. Carefully rotate the boom up and over

the top of the post (as shown in the diagram to the right) until it rests

on the top of the post.

Keep fingers out of the pinch point between the

brace and the boom (circled in the diagram).

Inspections and Maintenance

Crane owners and operators should regularly inspect this crane to confirm that it is in normal working

condition. Occupational Safety and Health Administration (OSHA) crane inspection procedures appear in 29 CFR

1910.179 (visit http://www.osha.gov/ and navigate to “Regulations” section 1910.179; relevant portions of those

procedures appear in paraphrase below).

1. Initial inspection — before using a new crane for the first time, inspect it to insure normal condition.

After the first use, conduct the following inspections:

2. Frequent inspection — inspect the following items for defects at the intervals indicated, including

observation during operation for any defects which might appear between inspections. All deficiencies such

as those listed shall be carefully examined to determine whether they constitute a safety hazard:

All functional operating mechanisms (pulley, cable, winch, post): inspect daily for maladjustment interfering

with proper operation. Verify that the winch rotates normally in both directions and locks automatically

when not rotating. The pulley should rotate freely as the cable extends and retracts. The post should rotate

smoothly and easily.

Load Hook: visually inspect the load hook before each use. Also inspect the hook once per month and

record the results of the inspection. Examine the hook for deformation or cracks. Immediately discard the

hook if it is cracked or if the throat opening is more than 15 percent in excess of normal throat opening.

Discard the hook if it is twisted more than 10° from the plane of the unbent hook.

All frame pieces (hitch tube, base frame, post, boom and boom brace) and all fasteners (bolts, nuts, pins):

Inspect weekly for damage: excessive wear, warps, and cracks. Replace all parts that are damaged before

using the crane again. All frame pieces should be square, rigid and free of rust and corrosion. Remove any

rust was a steel wool or a metal bristle brush and apply touch-up paint designed for coating metal and for

outdoor use.

Cable: Inspect weekly for reeving, kinks, frays, elongations, bird-caging, etc. Replace the cable if it is

damaged.

Pivot points: inspect all pivot points at least once per month, especially the connections between the

base frame and the post, for significant wear. Apply grease to the pivot points.