TABLE OF CONTENTS Rev. 9/13/2021 JIB-FM, MANUAL

TABLE OF CONTENTS Copyright 2021 Vestil Manufacturing Corp. Page 10 of 12

INSPECTIONS AND MAINTENANCE

NOTE: Inspection procedures are included in the most current revision of ASME B30.17. As stated above

in the NATIONAL STANDARDS section, Vestil recommends that you acquire a copy of the most recent

revision of this standard. Apply all use and maintenance/care instructions in the standard. Vestil also

recommends that you contact your local occupational health and safety authority to determine if any

laws, regulations, codes, ordinances, etc. apply inspection requirements where the crane is used.

Inspections and all necessary repairs should be performed by qualified persons. Compare the results of

each inspection to the RECORD OF SATISFACTORY CONDITION. Do not use the crane unless every part is

in satisfactory condition. DON’T GUESS! If you have any questions about the condition of your crane,

contact the TECHNICAL SERVICE department. The phone number is provided on the cover page of this

manual. Never make temporary repairs of damaged or missing parts. Only use manufacturer-approved

replacement parts to restore the crane to satisfactory condition.

A. Before and after each use (including first use), unload the crane and inspect the following

components:

1) I-Beam/Boom – Examine the beam, especially the lower flanges, welds, and regions around

fasteners, for bends, cracks, rusting/corrosion, and other forms of damage.

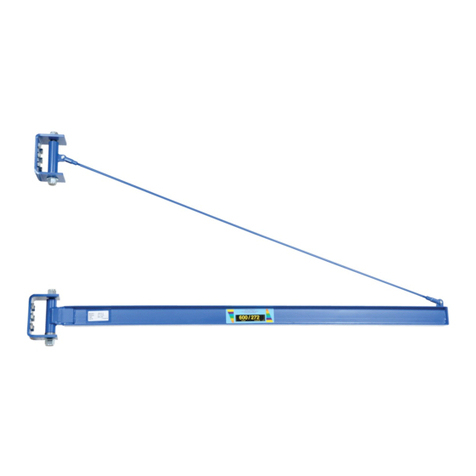

2) Beam Clamps and Beam Clamp Fasteners –Clamp connections are shown in Step 4 on p. 8. Verify

that all lock washers are fully compressed. The clamps of both sides of the beam should equally

overlap the I-beam flange.

3) Beam Bracket and Rear Bracket – Look for cracks, elongations around bolt holes, warps, bends, etc.

4) Foundation and Foundation/Anchor Bolts –Examine the foundation, particularly around the base of

the crane, for cracks, pitting, broken concrete, and other forms of damage. Inspect all anchoring

hardware (bolts, nuts, washers). Look for rusting/corrosion. Make sure that the mast is securely

anchored (i.e. does not wobble) to the foundation. All connections must be solid. Tighten loose nuts.

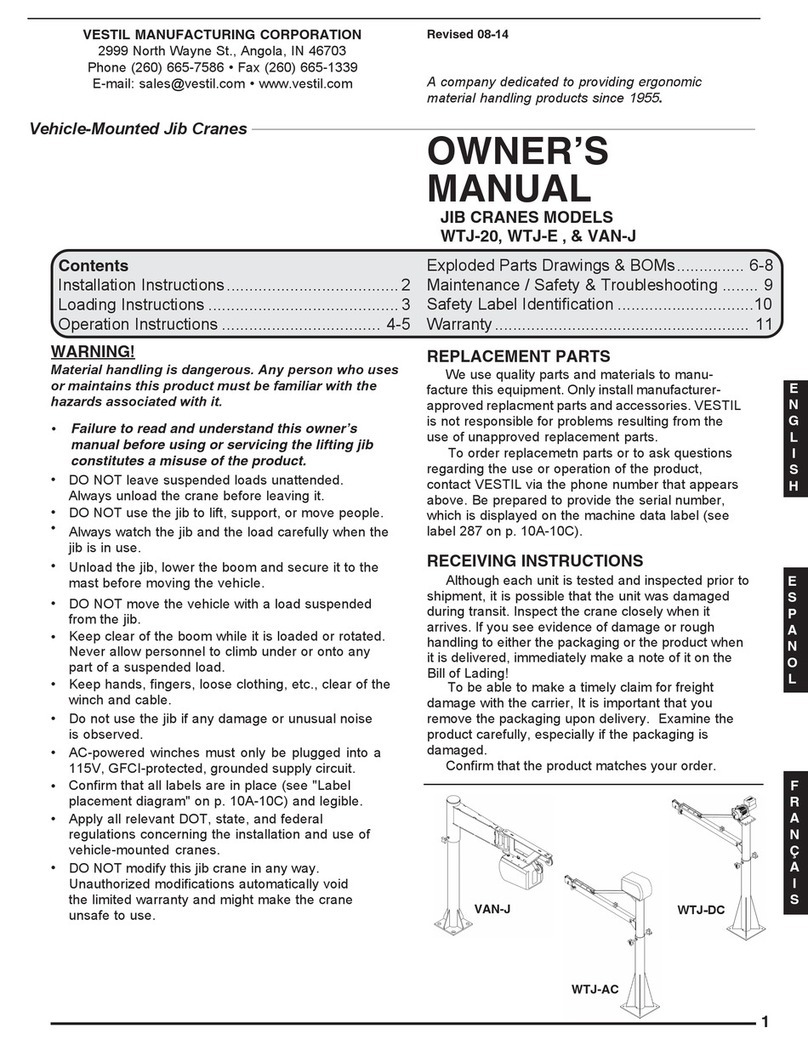

5) Socket, Rollers and Pins, Thrust Bearing, and Inner Bearing – Check all rollers, clevis pins, and cotter

pins. All clevis pins must be secured in place with cotter/spring pins. Rotate the boom. Rollers should

smoothly and quietly roll over the surface of the mast. Examine the rollers for cracks, significant wear,

and other forms of damage. The socket should not wobble as the boom rotates. Each roller must be

evenly worn and undamaged. The socket itself should be rigid and undamaged. Lubricate the inner

bearing whenever the boom becomes noisy while rotating or when its resistance to rotation

increases. Replace the inner bearing if noise and/or resistance is not improved with lubrication.

6) Boom/I-Beam –Check the boom and its mounting bracket for structural damage, i.e. severe wear,

bending, cracking, etc. Replace the entire boom assembly if structural damage is present.

7) Surface coating - Apply touch-up paint wherever the finish has been affected.

B. Monthly inspections – Unload the crane and inspect the following:

1) Beam Clamps and Beam Clamp Fasteners –Use a torque wrench to tighten each bolt and nut to

50-52ft∙lb. Examine all of the clamps for damage including deformations and cracks. The I-beam

flange should be solidly/immovably clamped to the tops of the uprights by the clamps

2) Beam Bracket and Rear Bracket – Look for cracks, elongations, broken concrete around bolt holes,

warps, bends, etc. Make sure that all fasteners are tightened to 94ft∙lb.

C. Once per year: Perform a load test. Lift a load equal to 125% of its rated load (capacity). Only lift the

load high enough to ensure that it is entirely supported by the crane. Transport the load by means of your

hoist (or hoist & trolley) the full usable length of the I-beam (dimension E in SPECIFICATIONS diagram and

table on p. 2). Return the test load to the ground. Perform inspections A (Before and after each use) and

B (Monthly). NOTE: Perform this part C (Load test and a Before & after use inspection) whenever the crane

is partially or fully disassembled and reassembled, e.g. after installing replacement parts.