f) Press patch firmly onto

prepared area of the

bag and rub.

g) Leave bag at least 48

hours in deflated state.

The bag should be tested

by a safety expert after the

repair.

Recurrent tests

Tests for lifting bags are

based on the Pressure

Vessel Legislation and DIN

14152 Part 1*.The tests

contained herein are to be

carried out as specified.

Lifting bags with a maxi-

mum working pressure of

0.5 bar / 7.25 psi do not

have to be tested by a

safety expert but can be

tested by a qualified tester.

Vetter Lifting Bags 0.5 bar /

7.25 psi are subjected to a

constructional and pres-

sure test as well as an

approval test in accordance

with § 9 of the Pressure

Vessel Legislation by a

work’s tester.

If this ices up because of a

excess atmospheric

humidity in connection with

low temperatures use a

normal defroster (such as

is used for car locks).

Maintenance and

servicing

Minor damage such as

cracks, cuts or punctures

can be repaired by the user

with the enclosed repair kit

as follows:

a) Select a patch which is

approx. 5 cm larger

than the damage on all

sides.

b) Mark patch on bag.

c) Roughen up the surface

of the bag and one side

of the patch.

d) Apply a thin layer of

special adhesive on the

roughened up surface

of the bag and the

patch.

e) Leave special adhesive

approx. 20 minutes to

dry until no longer tacky.

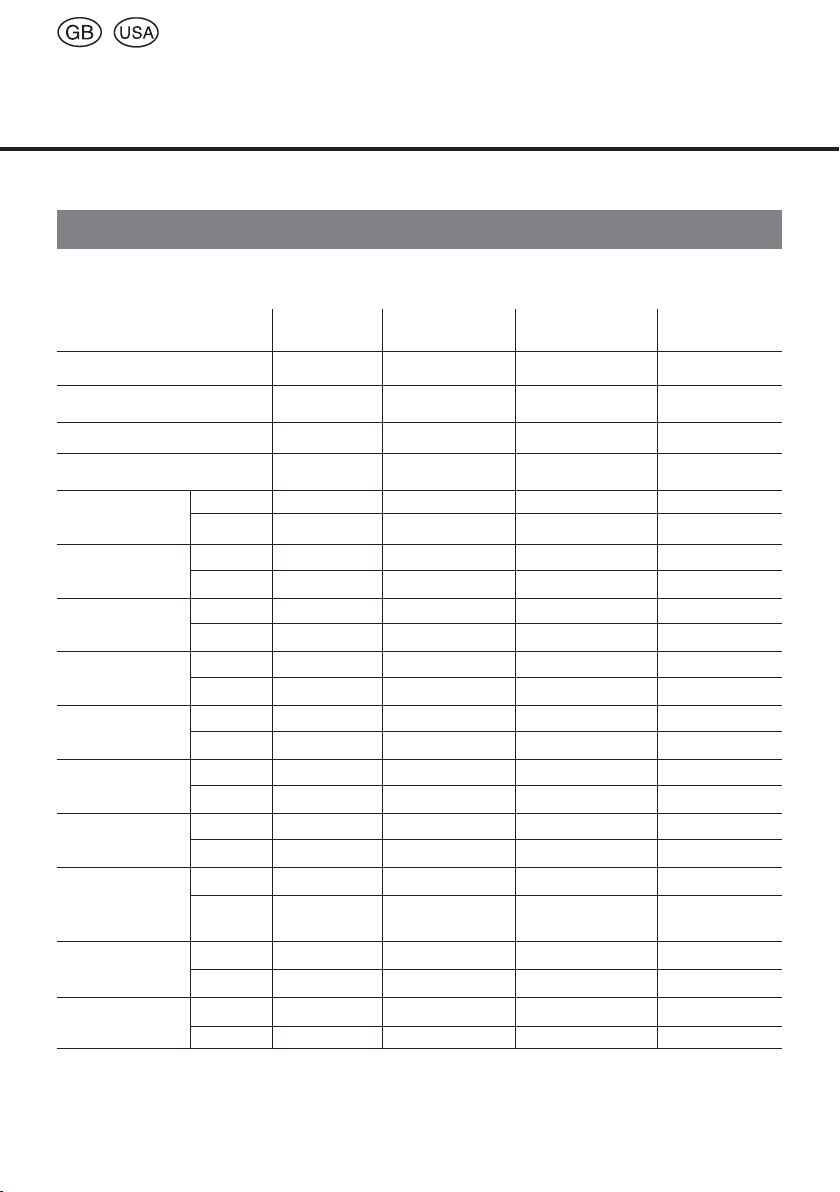

Performance of tests

Tests on delivery by user

During this test in accord-

ance with DIN 14 152 Part

1, Item 5.2*the device

should be checked by the

user’s qualified tester to

ensure that all parts have

been delivered and that

none are damaged.The

bags are to be inflated up to

0.2 times the permissible

working pressure, i.e. to 0.1

bar / 1.5 psi.The qualified

tester should then perform

a visual check.

Recurrent tests

The lifting bag system

should be checked after

every use, though at the

latest after one year, to

ensure that all parts are

complete and none are

damaged. If all parts are

complete and present the

lifting bag should be in-

flated to 0.5 times the

maximum working pres-

sure of 0.5 bar / 7.25 psi,

i.e. 0.25 bar / 4 psi, and

then washed with luke-

warm soapy water. Check

for cracks, wear, cuts or

19

*Pressure Vessel Legislation and DIN 14152 Part 1 are only valid in Germany.