3 4

INSTALLATION:

1. Removethetopofthecalciumreactor.Rinsecalciumreactormedia.Placeaspongeover

thebottomsupportgrid.Addapproximately10inofmediatothereactor.Whenadding

mediaverifythatmediadoesnotgodownthestandpipe.Placeanotherspongeoverthetop

supportgripabovethemedia.Latchlidbackontothecalciumreactorandverifythatthe

outputisconnectedtothestandpipe.

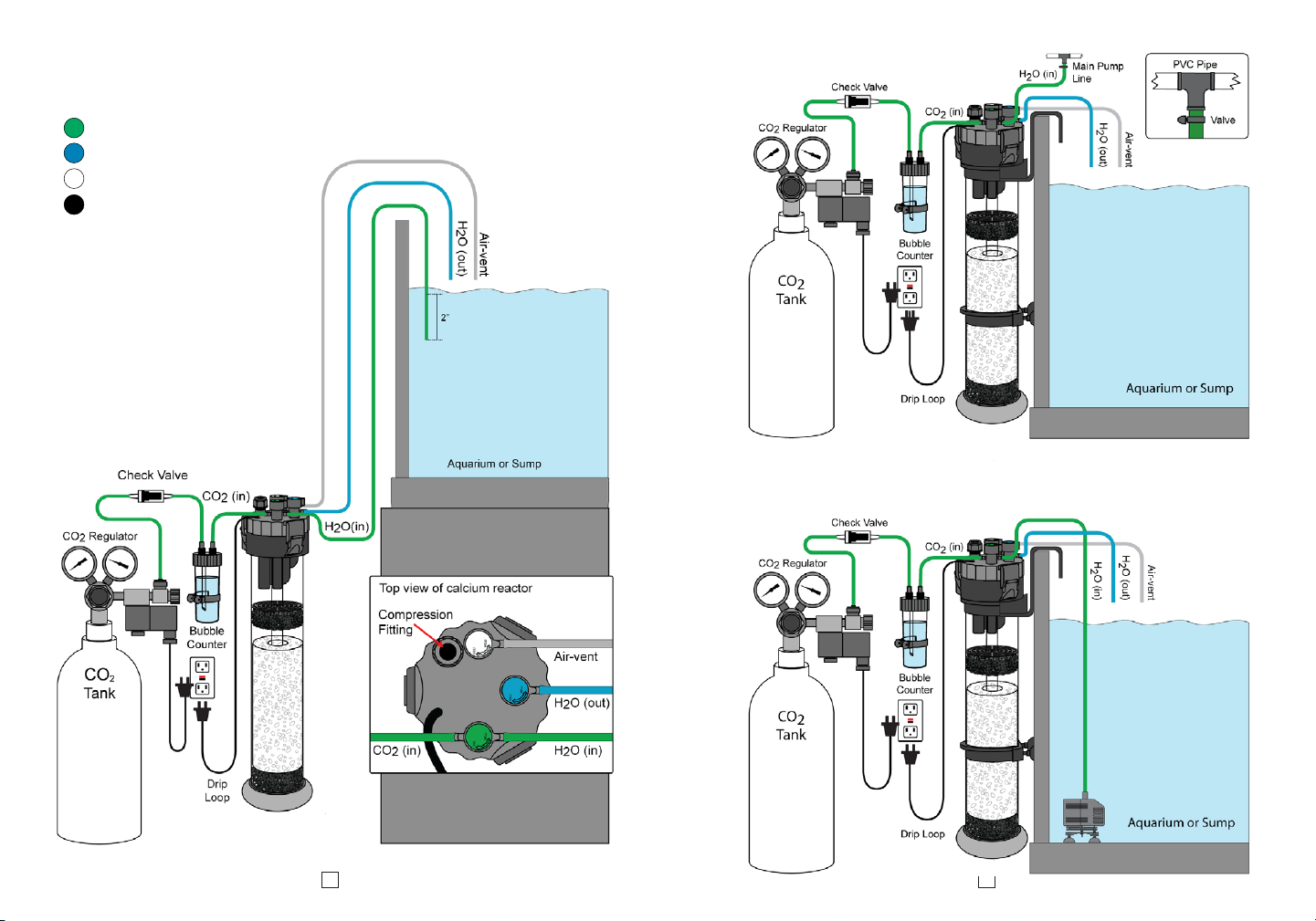

2. Chooseoneofthefollowingwatersource(in):

a)Gravity(unitinstalledbelowaquarium):Connectapieceofsiliconetubingtothegreen

waterintakevalve,insertthelineinsidetheaquarium2inbelowthewatersurface.

Thetubecanbesecureddirectlytotheoverowboxusingaziptie.

b)Pressure:Chooseanexistingpressureline.Cutthelineandplumbinatee.Thebleedline

willsupplywatertothecalciumreactor.Thebleedlinemusthaveavalveandreduced

to3/16inbarb.Withthevalveclosedconnectsthesiliconetubingfromthebleedline

directlytothegreenwaterintakevalve.

c)Supplypump:Useaseparatelowowpump.Reducetheoutputofthepumpto3/16in

barb.Connectsiliconetubingdirectlytothegreenwaterintakevalve.Dependingonthe

sizeofthepump,ableedlineisneededtokeepwaterowingthroughthepump

atalltimes.

3. Efuentwater(out):Connectsiliconetubingtotheblueefuentwatervalve.Securetheline

tothebackoftheaquariumor

sump.Thesiliconetubingmust

bepositionedabovewaterlevel

sothatyoucanseedropletsof

waterowingfromthetube.

4. Fillbubblecounterthree

quartersfullwithfreshwater.

5. CO2/Waterintake(in):Attach

thesiliconetubingfromthe

CO2regulatortoacheckvalve

tothebubblecounterandtothe

CO2greenwaterintakevalve.

Seediagram.

6. Air-vent-bleed:Attachsilicone

tubingtothewhiteair-vent-

bleedvalve.Securesilicone

tubingtotheaquariumorsump.ThishelppreventsairandCO2frombuildingupatthetop

ofthecalciumreactor.

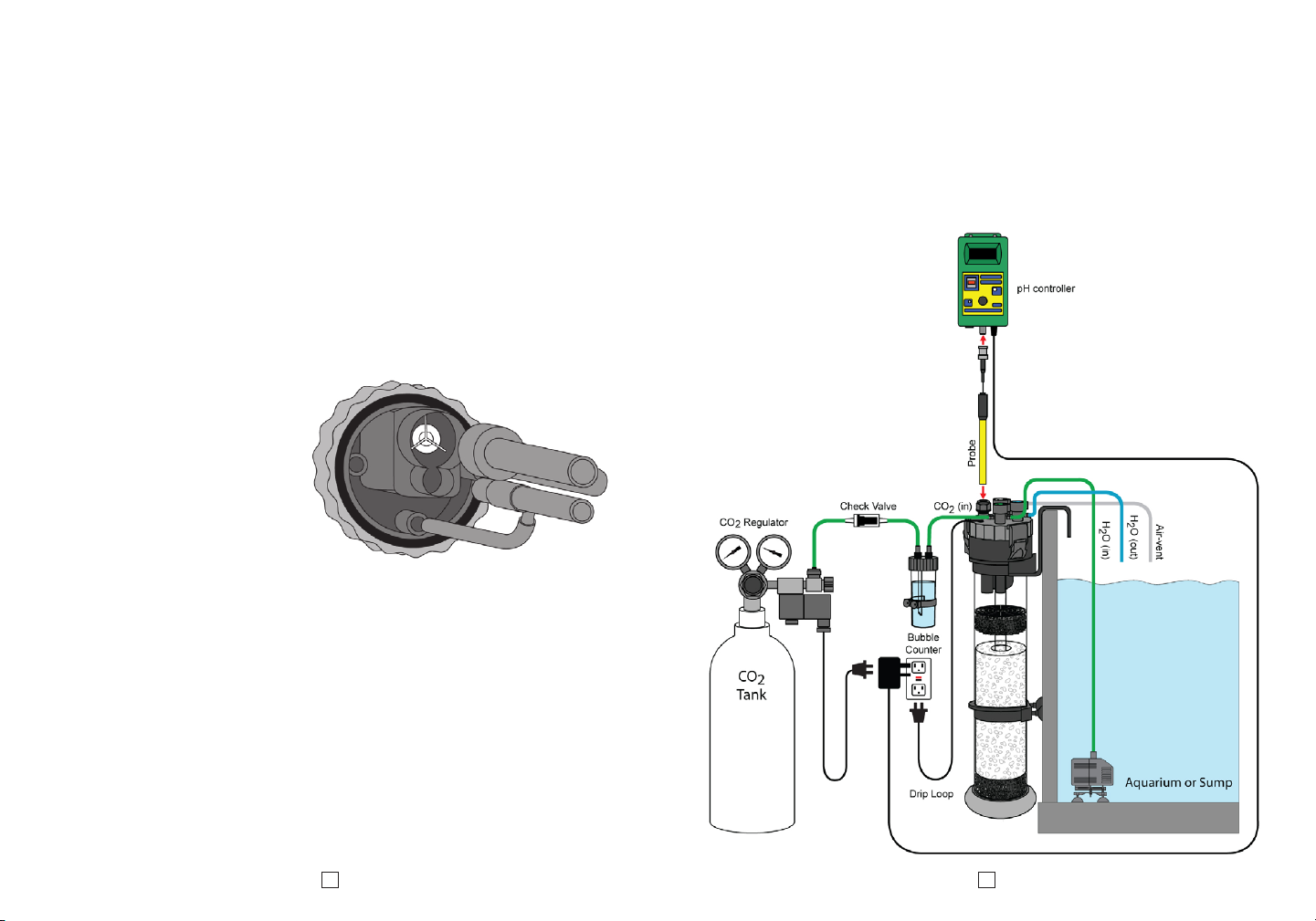

7. WhenusingapHcontrollerandprobe,twistoffthecapofthecompressiontting.Remove

therubberplug.Slideonthecompressionttingoverthesensorprobe.Insertprobeintothe

compressionttingandhandtightennuttoseal.SeeinstructionsforpHcontrollerandprobe

(page7)

8. PrimingCalciumReactor:

a)Gravity:Openthegreenwaterintakevalve.Disconnectthetubingfromthegreenwater

intakevalve,applysuctiontostartasiphonandreattachitbacktothegreenwaterintake

valve.Keepthewhiteair-vent-bleedvalveopenuntilthecalciumreactorisfullofwater.

b)Pressure:Openthegreenwaterintakevalve,thenthewhiteair-vent-bleedvalve(this

valvemaynothavetobeopenedalltheway).Whenastrongpumpisused,thewhite

air-vent-bleedvalveonlyneedstobeopenaquarterturn.Closethewhiteair-vent-bleed

valvecompletelywhenthecalciumreactorisfullofwater.

c)Supplypump:Openthegreenwaterintakevalve.PlugthepumpintoaGFCIoutlet.

Openthewhiteair-vent-bleedvalveuntilthecalciumreactorisfullofwater.

9. Oncethecalciumreactorisprimed,closewhiteair-vent-bleedvalve.Ifairisaccumulated

inthecalciumreactor,openwhiteair-vent-bleedvalveandleavethegreenwaterintake

valveopen.

10. Turnonthepumpandwaituntilthewaterclears.Opentheblueefuentwatervalve.

Adjustthevalvesothereisabrokenstreamofwaterdischargingfromthetube.Setthe

valveasslowaspossiblewithoutbeingabletocountanydroplets.

11. TurnontheCO2controlvalve.AdjusttheCO2regulatortoproduce60bubblespermin.

inthebubblecounterchamber.TheCO2inputisdirectlyrelatedtowaterowrate:

• ToraisepHinefuentwaterincreasewaterowordecreaseCO2

• TolowerpHinefuentwaterdecreasewateroworincreaseCO2

12. ApHmeter/controllerisrecommendedtomaintainaproperlevelofpHintheaquarium.

CollectasmallamountofefuentwaterandtestitwithapHmeter.Initiallyadjustthe

CO2atpH7.5.MonitorthepHintheaquariumandverifythatit’snotdroppingfast.If

pHdropsrapidly,decreaseCO2immediately.Atalltimes,thepHoftheaquariumshould

beover8.0.TheidealpHoftheefuentwatershouldbe6.5to7.5.Ittakesapproximately

twoweekstostabilizethepHoftheefuentwatertotheideallevel.Continueincreasing

ordecreasingtheCO2orefuentwateramountasneededtoachieveoptimumpHlevel.

13. After24hours,measurethecarbonatehardnessoftheefuentwater.Thehardnesslevel

shouldbearound12-16dKH.Calciumlevelswillincreasebuttherateitincreasesdepend

onthetypeofmediaused.OceanpureTMCalciumReactorMediaisrecommended.

14. ContinueaddingthecalciumuntiltheCalciumReactorstartstowork.