Vicking electronics Pag. 4

Barcode port 1 Right DIN connector In the default setting the right and left DIN connector gives the

same software code, so the user can choose where he plugs in

the barcode reader.

Left DIN connector Can be programmed to give a different software code as the

right connector if the application demands it.

Barcode port 2 Internal molex connector Can’t be used if the left DIN connector is also used.

This connector is used if you want to prevent the user from

easily disconnecting the barcode reader.

Proximity / magnetic card readers

The workmate can read magnetic cards that have data on track2

in accordance with the international standard ISO 2 ABA.

Character encoding: 4 bits plus a parity bit.

Track encoding: START(13) DATA END(15) LRC maximum 38 characters.

The magnetic card readers and the proximity readers both use the same protocol and the same connectors,

but some connections are reserved only for proximity.

There are 2 ways to connect a magnetic card reader to the WORKmate:

Prox. port 1 Internal molex connector If the reader must be permanently connected to the

WORKmate.

Prox. port 2 Left DIN connector The installation is easier through this connector, but can be

disconnected by the user.

Both connections can be used at the same time.

There are 4 ways to connect a proximity reader to the WORKmate:

Internal proximity reader A proximity module can optionally be mounted directly on the

WORKmate mainboard.

Prox. port 1 Internal molex connector To connect to an internal proximity board. Or an external

proximity reader a short distance from the WORKmate that

can’t be disconnected easily.

Left DIN connector You can connect an external proximity reader a short distance

from the WORKmate via the left DIN connector.

Prox. port 2 Opto-coupled interface

on the I/O board If you want to connect an external proximity reader a long

distance from the WORKmate you need to install the extra I/O

board.

Both port can have a reader connected at the same time.

Like the barcode readers, you can setup the ports to generate the same or a different software code.

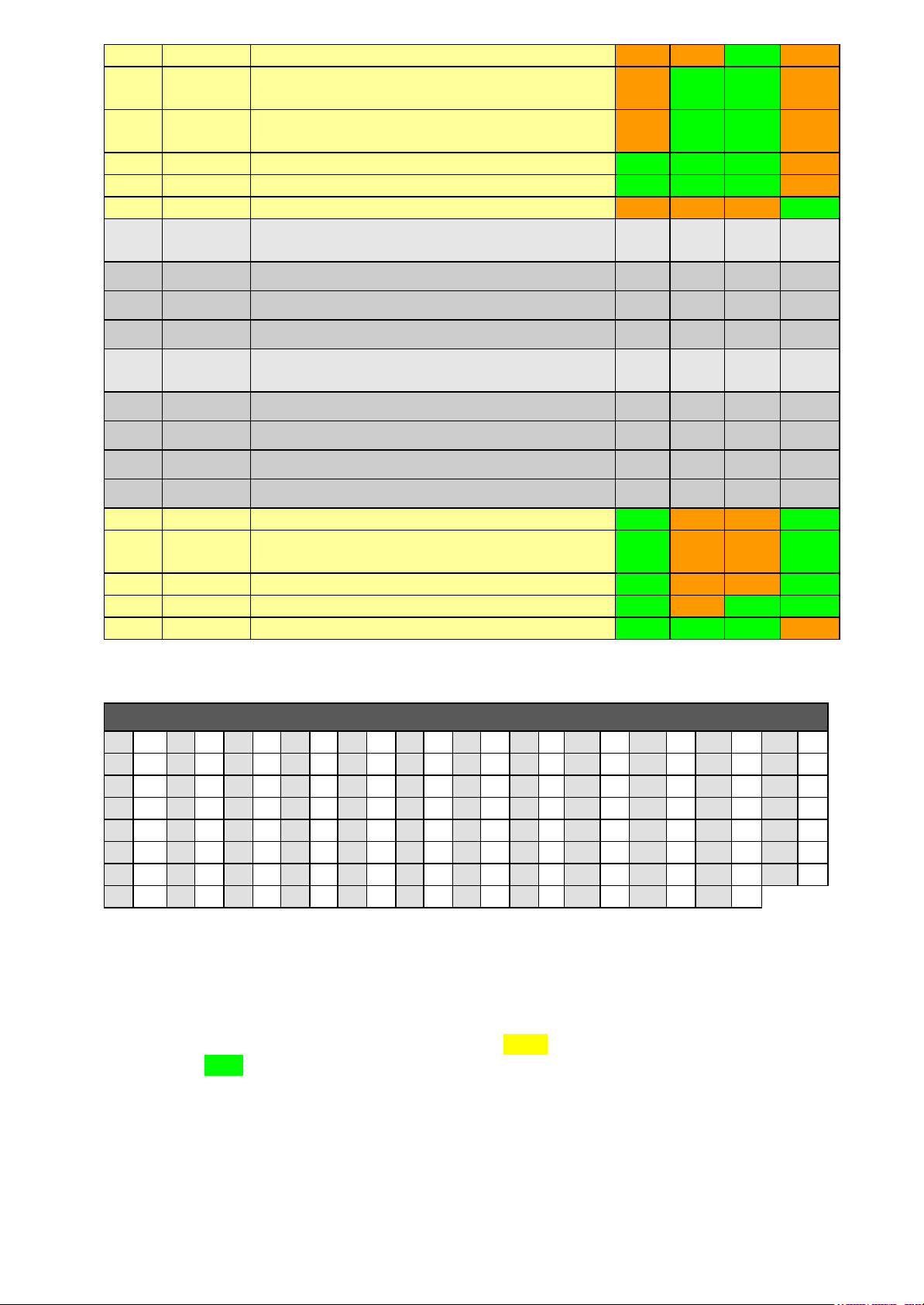

Input / Output

Each DIN connector has one output pin. These outputs are not buffered with a relays, they are directly

connected to the WORKmate transistors. These outputs are used in special interfaces connected to the

WORKmate.

You need the I/O board if you want more powerful outputs.

Each DIN connector has an input pin, you must connect a switch to these inputs (from ground pin 2 to the

input pin 7). The inputs are only meant to detect if a switch in on or off. Do not connect an external voltage to

the input pins. You need the I/O board if you want more powerful inputs.