4 | 028-0323-02_LIT-VZ7656R&VZ7656H_W-E01_EN www.viconics.com September 2019

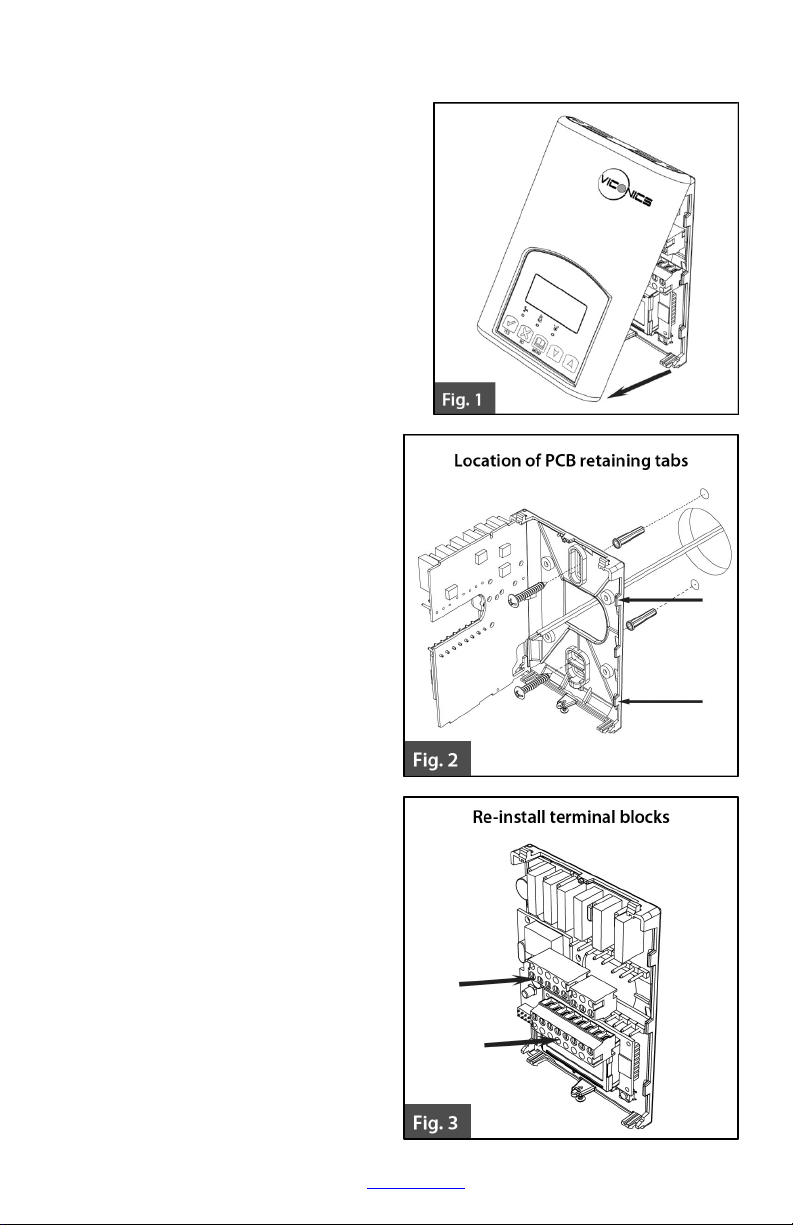

Installation

•The system must be installed correctly by a qualified technician.

•If replacing an existing Room Controller, label wires before removal of Controller.

•Electronic controls are static sensitive devices. Discharge yourself correctly before

manipulating and installing Room Controller.

•A short circuit or wrong wiring may permanently damage Room Controller or equipment.

•All Room Controllers are designed for use as operating controls only and are not safety

devices. These instruments have undergone rigorous tests and verification prior to shipping

to ensure proper and reliable operation in the field. Whenever a control failure could lead to

personal injury and/or loss of property, it becomes the responsibility of the

user/installer/electrical system designer to incorporate safety devices (such as relays, flow

switch, thermal protections, etc.) and/or an alarm system to protect the entire system

against such catastrophic failures. Tampering with the devices or unintended application of

the devices will result in a void of warranty.

•This device must be installed to provide a separation distance of at least 8in (20cm) from all

persons and must not be located or operating in conjunction with any other antenna or

transmitter.

•Refer to the Room Controller User Interface Guide for information on how to configure the

Room Controller.

Failure to follow these instructions can result in equipment damage.

Location

•Do not install on an exterior wall.

•Do not install behind a door.

•Do not install in areas with direct heat source.

•Do not install near any air discharge grill.

•Do not install in areas exposed to direct sunlight.

•Ensure Room Controller has sufficient natural air circulation.

•Ensure wall surface is flat and clean.

•Ensure external thermal sensor wirings are away from noisy electrical sources.

•Install 1.3 to 1.5 meter (52 to 60 inches) above the floor.

•Perform preventive maintenance on the damper and Variable Air Volume (VAV) box,

according to the supplier documentation.

Failure to follow these instructions can result in equipment damage.

Cleaning the Room Controller

CLEANING THE ROOM CONTROLLER

•Use a soft, pre-moistened lint-free cloth for cleaning.

•Avoid getting moisture in openings.

•Do not spray anything directly on the Room Controller or use compressed air.

•Do not use caustic/corrosive products, ammonia, solvents or any cleaning product

containing alcohol or grit.

•Never use tools directly on the touchscreen.

•Never use paint on the Room Controller.

•Do not drop or crush the Room Controller, or allow it to come into contact with liquids.

•Do not use a damaged device (such as one with a cracked screen).

Failure to comply with these recommendations will result in damage to the unit and

void the manufacturer’s warranty.