Design Guide & Applications Manual

For VI-200 and VI-J00 Family DC-DC Converters and Configurable Power Supplies

VI-200 and VI-J00 Family Design Guide Rev 3.4 vicorpower.com

Page 4 of 97 Apps. Eng. 800 927.9474 800 735.6200

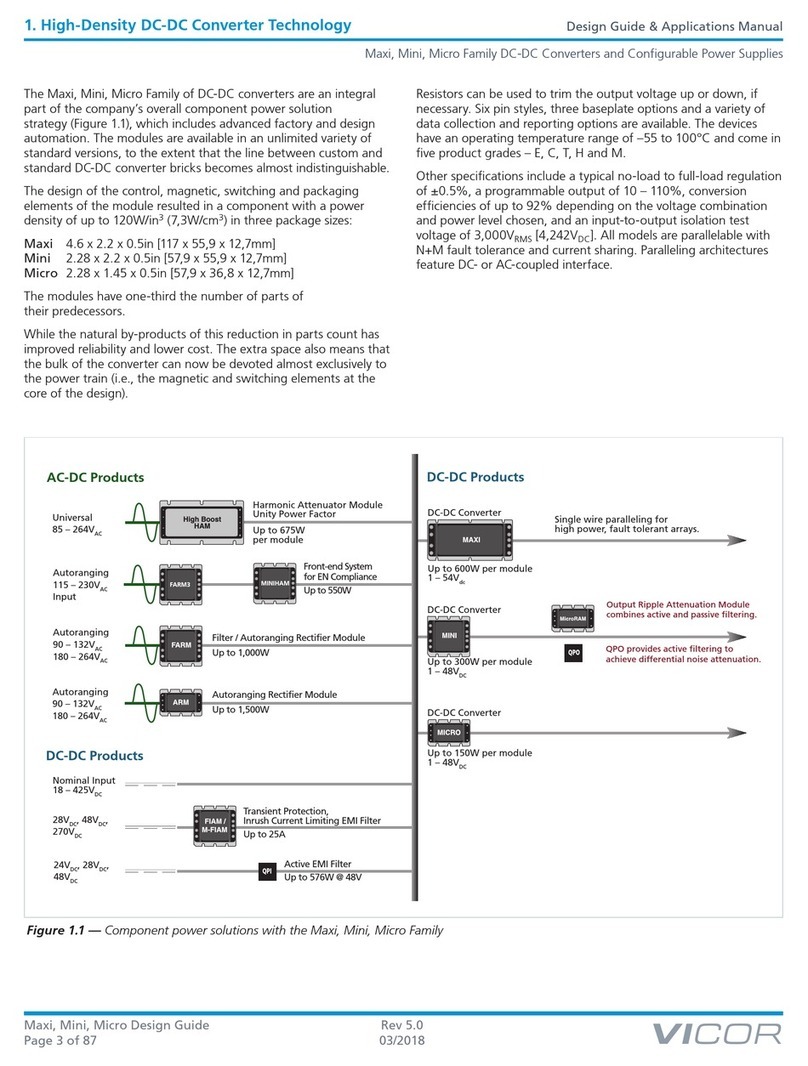

ELECTRICAL CONSIDERATIONS

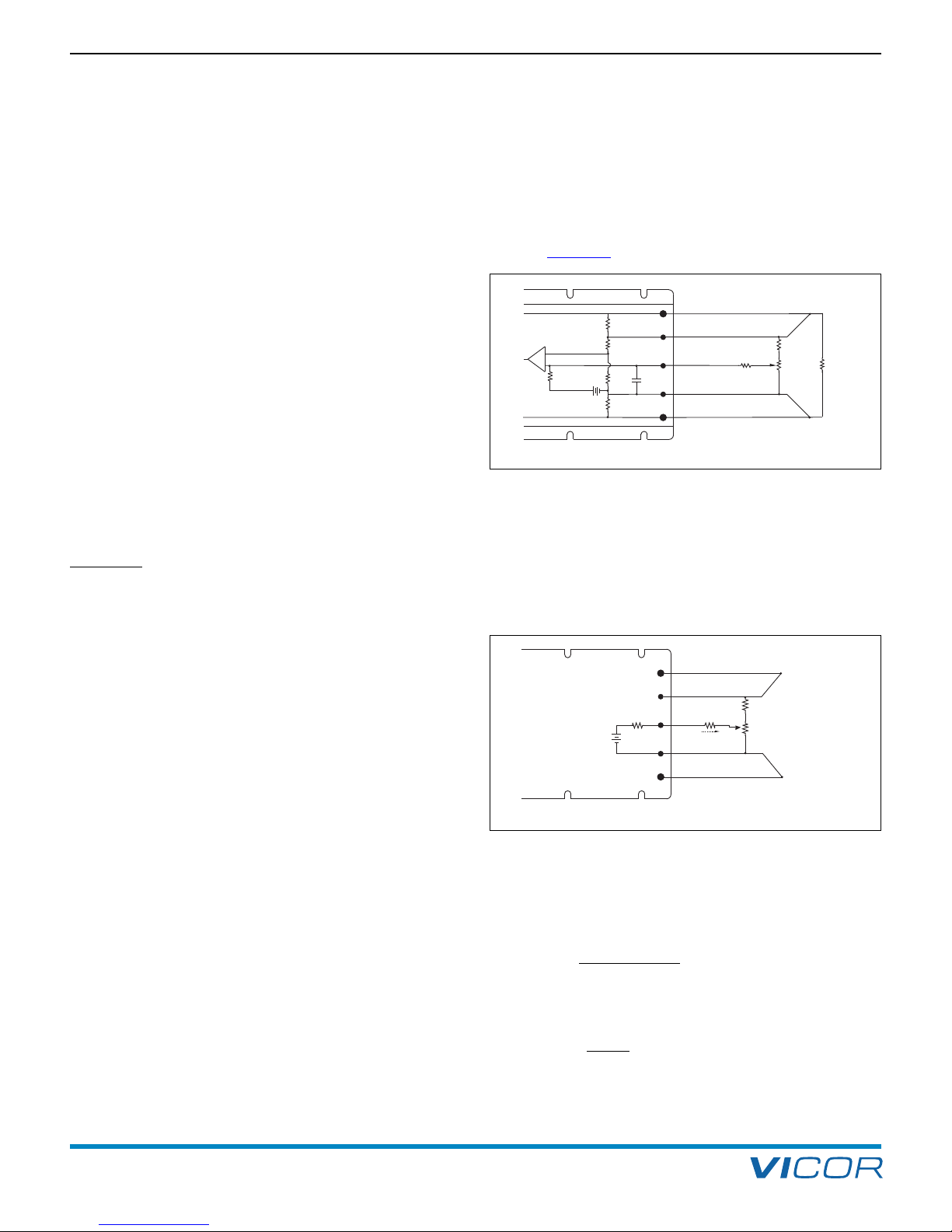

GATE IN AND GATE OUT PINS

Logic Disabl . When power is applied to the input pins,

the GATE IN pin of a Driver can be pulled low with respect

to the –IN thus turning off the output while power is still

applied to the input. (Figure 7–1)

CAUTION With offline applications –IN is not

earth ground.

In Logic Disable mode, the GATE IN pin should be driven

from either an “open collector” or electromechanical

switch that can sink 6 mA when on (GATE IN voltage less

than 0.65 V). If driven from an electromechanical switch

or relay, a 1 µF capacitor should be connected from GATE IN

to –IN to eliminate the effects of switch “bounce”. The 1 µF

capacitor may be required in all applications to provide a

“soft start” if the unit is disabled and enabled quickly. Do

not exceed a repetitive on / off rate of 1 Hz to the GATE

IN or input voltage pins.

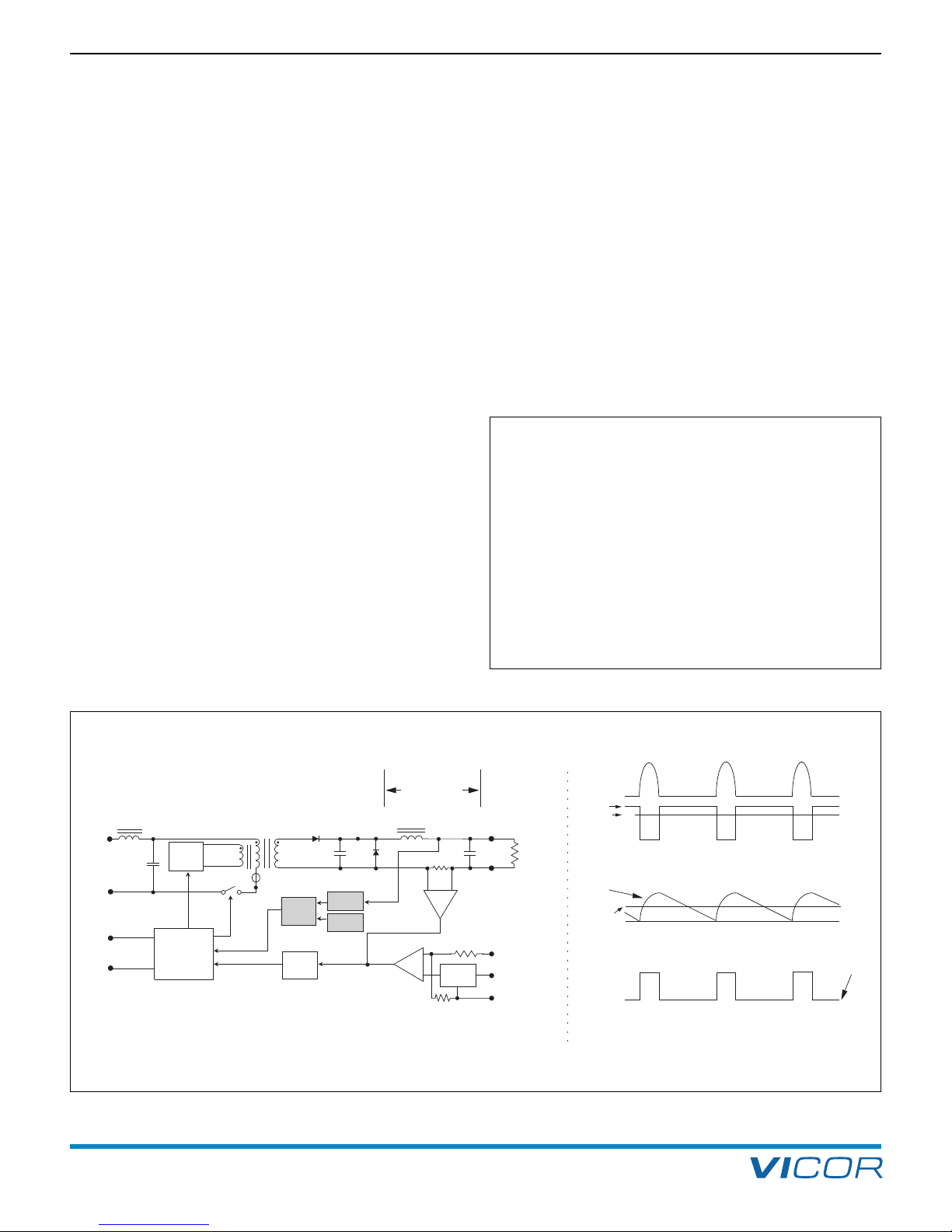

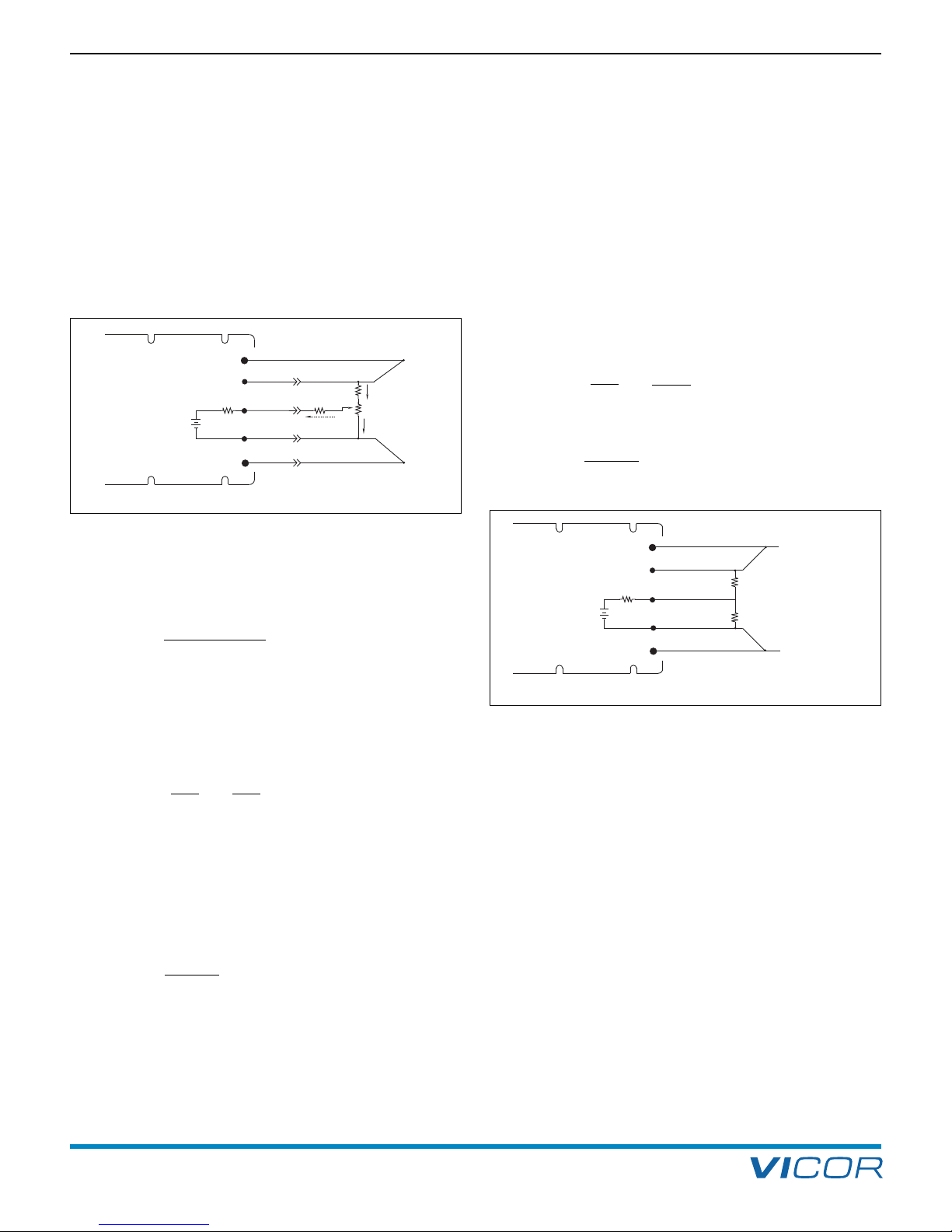

High Pow r Arrays. The pulsed signal at the GATE OUT

pin of a regulating Driver module is used to synchronously

drive the GATE IN pin of a companion Booster module to

effect power sharing between the Driver and the Booster.

(Figure 7–5) Daisy-chaining additional Boosters (i.e.,

connecting GATE OUT to GATE IN of a succeeding unit)

leads to a virtually unlimited power expansion capability.

VI-/MI-200 series modules of the same family and power

level can be paralleled (i.e., Driver, VI-260-CU with

Booster, VI-B60-CU).

In general:

• Don’t drive the GATE IN pin from an “analog”

voltage source.

• Don’t leave GATE IN pins of Booster modules

unterminated.

• Don’t overload GATE OUT; limit load to a single Vicor

module GATE IN connection, or 1 kΩ, minimum, in

parallel with 100 pF, maximum.

• Don’t skimp on traces that interconnect module –IN

pins in high power arrays. GATE IN and GATE OUT

are referenced to –IN; heavy, properly laid out traces will

minimize parasitic impedances that could interfere with

proper operation.

• Do use a decoupling capacitor across each module’s

input (see Input Source Impedance that follows).

• Do use an EMI suppression capacitor from +/– input and

output pins to the baseplate.

• Do use a fuse on each module’s + input to prevent fire

in the event of module failure. See safety agency

conditions of acceptability for the latest information on

fusing. Please see the Vicor website

for Safety Approvals.

Input Sourc Imp danc . The converter should be

connected to an input source that exhibits low AC

impedance. A small electrolytic capacitor should be

mounted close to the module’s input pins. (C3, Figure 3–1)

This will restore low AC impedance, while avoiding the

potential resonance associated with “high-Q” film

capacitors. The minimum value of the capacitor, in

microfarads, should be C (µF) = 400 ÷ Vin minimum.

Example: Vin, minimum, for a VI-260-CV is 200 V. The

minimum capacitance would be 400 ÷ 200 = 2 µF. For

applications involving long input lines or high inductance,

additional capacitance will be required.

The impedance of the source feeding the input of the

module directly affects both the stability and transient

response of the module. In general, the source impedance

should be lower than the input impedance of the module

by a factor of ten, from DC to 50 kHz.

To calculate the required source impedance, use the

following formula:

Z = 0.1(VLL)2/ Pin

where: Z is required input impedance

VLL is the low line input voltage

Pin is the input power of the module

Filters, which precede the module, should be well damped

to prevent ringing when the input voltage is applied or

the load on the output of the module is abruptly changed.

Input Transi nts. Don’t exceed the transient input

voltage rating of the converter. Input Attenuator Modules

or surge suppressors in combination with appropriate

filtering, should be used in offline applications or in

applications where source transients may be induced by

load changes, blown fuses, etc. For applications where the

input voltage may go below low line it is recommended

that an undervoltage lockout circuit be used to pull GATE

IN low to disable the converter module. The undervoltage

lockout circuit should induce a delay of at least one

second before restarting the converter module. Longer

delays will be required if external capacitance is added at

the output to insure the internal soft-start is re-initialized.

NOTE Do not allow the rate of change of the input

voltage to exceed 10 V/µs for any input voltage deviation.

The level of transient suppression required will depend on

the severity of the transients. A Zener diode, TRANSZORB™

or MOV will provide suppression of transients under 100 µs

and act as a voltage clipper for DC input transients. It may

be necessary to incorporate an LC filter for larger energy

transients. This LC filter will integrate the transient energy

while the Zener clips the peak voltages. The Q of this filter

should be kept low to avoid potential resonance problems.

See Section 14, Input Attenuator Module (IAM/ MI-IAM)

for additional information on transient suppression.

3. Module Do’s and Dont’s