DC Inverter Duct Type Unit

7

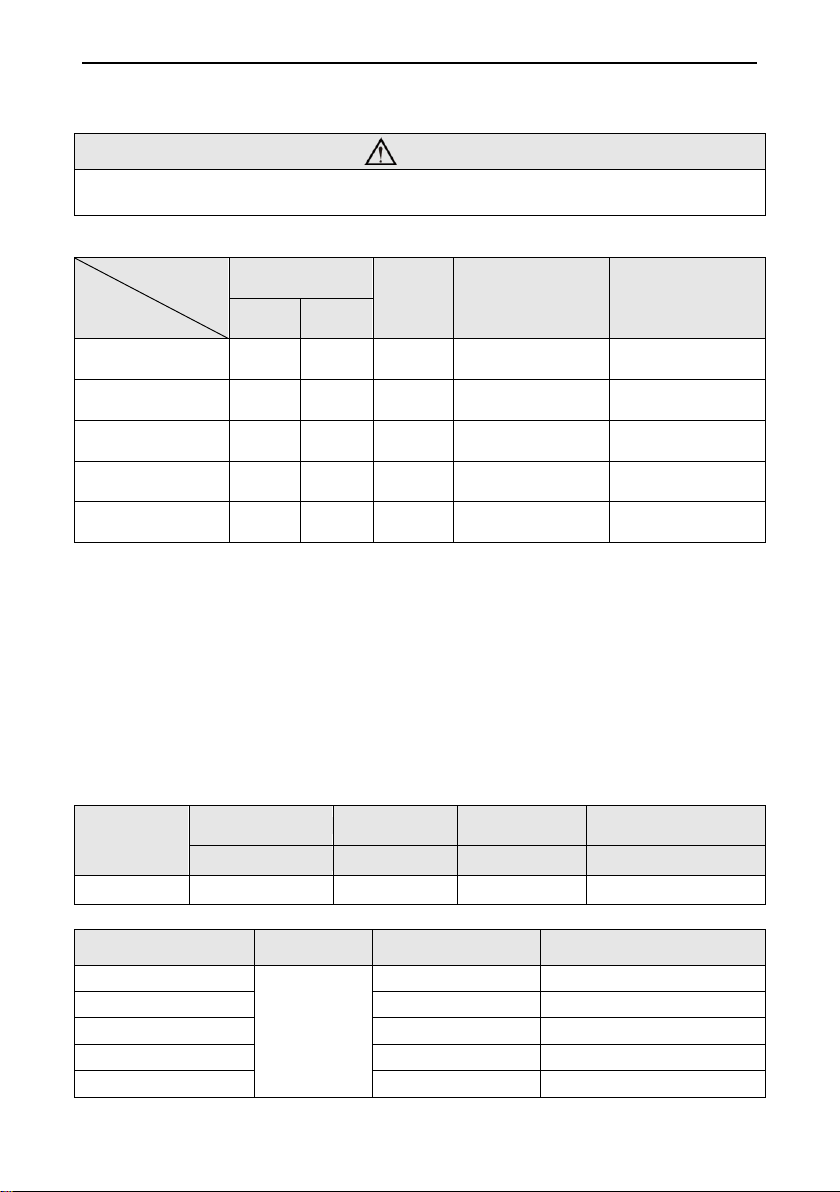

Notes:

①. The fuse is located on the main board.

②. Install the disconnect device with a contact gap of at least 3 mm in all poles

nearby the units (Both indoor unit and outdoor unit).The appliance must be

positioned so that the plug is accessible.

③. The specifications of the breaker and power cable listed in the Table above

are determined based on the maximum power (maximum amps) of the unit.

④. The specifications of the power cable listed in the Table above are applied

to the conduit-guarded multi-wire copper cable (like, YJV copper cable,

consisting of PE insulated wires and a PVC cable jacket) used at 40°С and

resistible to 90°С(see IEC 60364-5-52). If the working condition changes,

they should be modified according to the related national standard.

⑤. The specifications of the breaker listed in the Table above are applied to

the breaker with the working temperature at 40°С. If the working condition

changes, they should be modified according to the related national

standard.

⑥. Take 2 pieces of power cord of 0.75mm2as the communication lines

between indoor and outdoor unit, with their longest lengths of 50m. Please

select the appropriate line length as per the actual installation conditions.

The communication lines can not be twisted together. For the unit (≤30K),

it’s recommended to use 8m long communication line.

⑦. Take 2 pieces of power cord of 0.75mm2as the communication lines

between the wired controller and the indoor unit, with their longest lengths

of 30m. Please select the appropriate line length as per the actual

installation conditions. The communication lines can not be twisted

together. It’s recommended to use 8m long communication line.

⑧. The wire size of the communication line should be no less than 0.75mm2.

It’s recommended to take 0.75mm2power cords as the communication line.

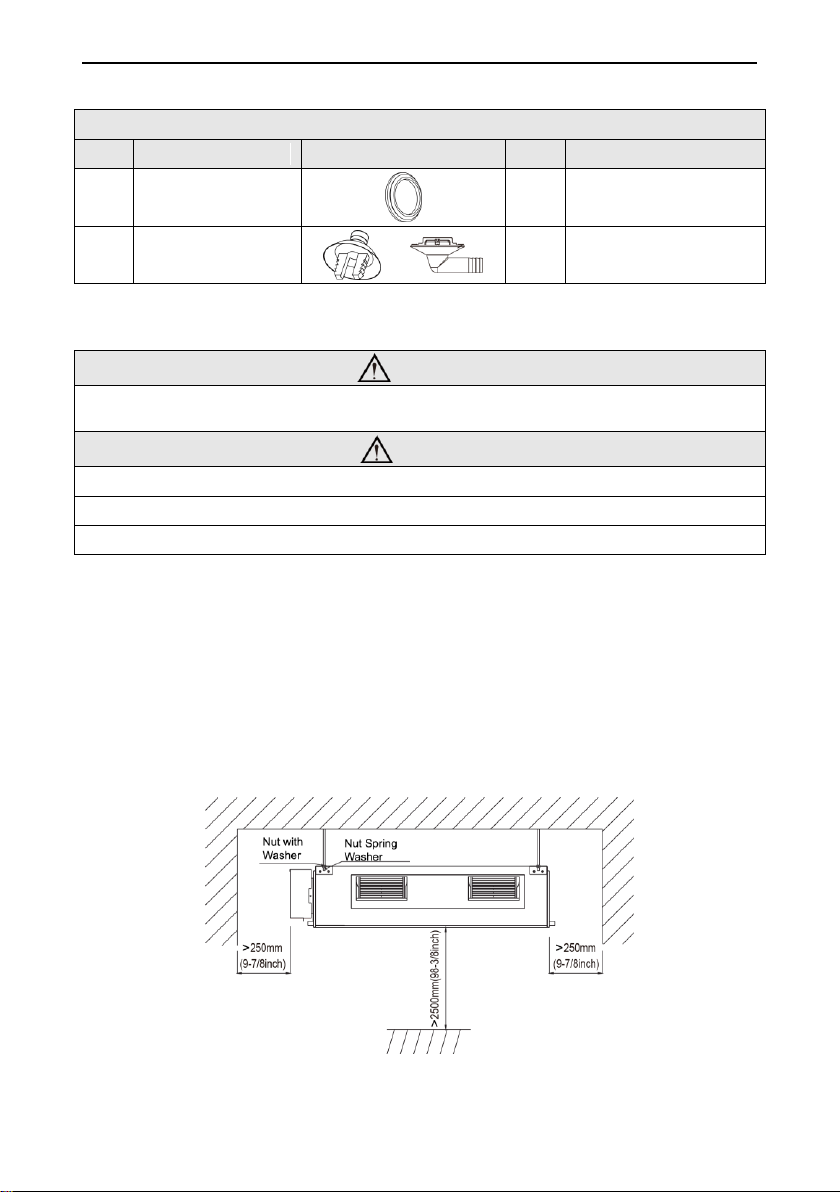

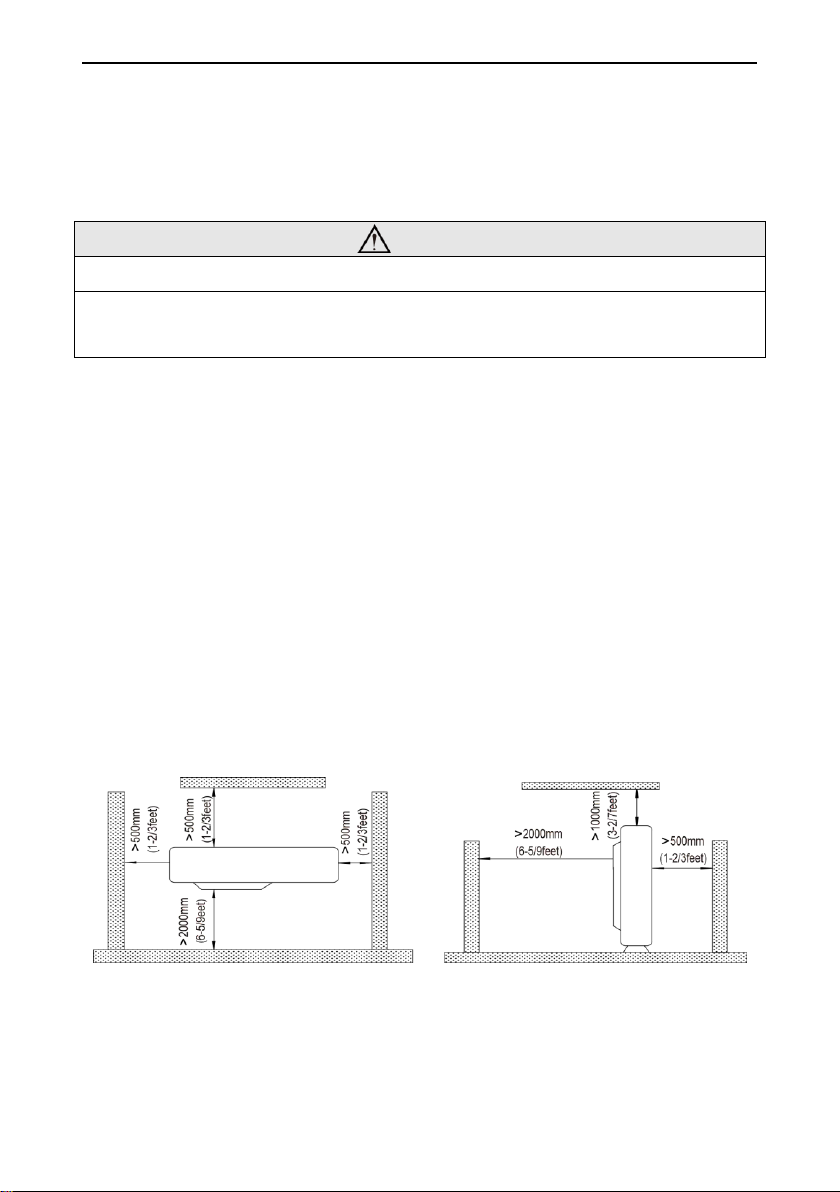

4 Installation of the Unit

4.1 Installation of the Indoor Unit

4.1.1 Indoor unit dimension