Table of Contents

1. Introduction ........................................................................................................................... 1

1.1. The Lynx Smart BMS ....................................................................................................... 1

2. Features ................................................................................................................................ 2

2.1. Batterie Management System ............................................................................................. 2

2.2. Contactor ..................................................................................................................... 2

2.3. Built-in pre-charge circuit ................................................................................................... 2

2.4. Battery Monitor .............................................................................................................. 2

2.5. Programmable relay ......................................................................................................... 2

2.6. AUX terminal ................................................................................................................. 2

3. Communication and interfacing ................................................................................................... 3

4. System Design considerations and examples .................................................................................. 4

4.1. Integration into the Lynx Distributor System .............................................................................. 4

4.2. System sizing ................................................................................................................ 5

4.2.1. Current rating Lynx Smart BMS ................................................................................. 5

4.2.2. Fusing .............................................................................................................. 5

4.2.3. Cabling ............................................................................................................. 5

5. Installation ............................................................................................................................. 6

5.1. Safety Precautions .......................................................................................................... 6

5.1.1. Safety Warnings Lynx Distribution System ..................................................................... 6

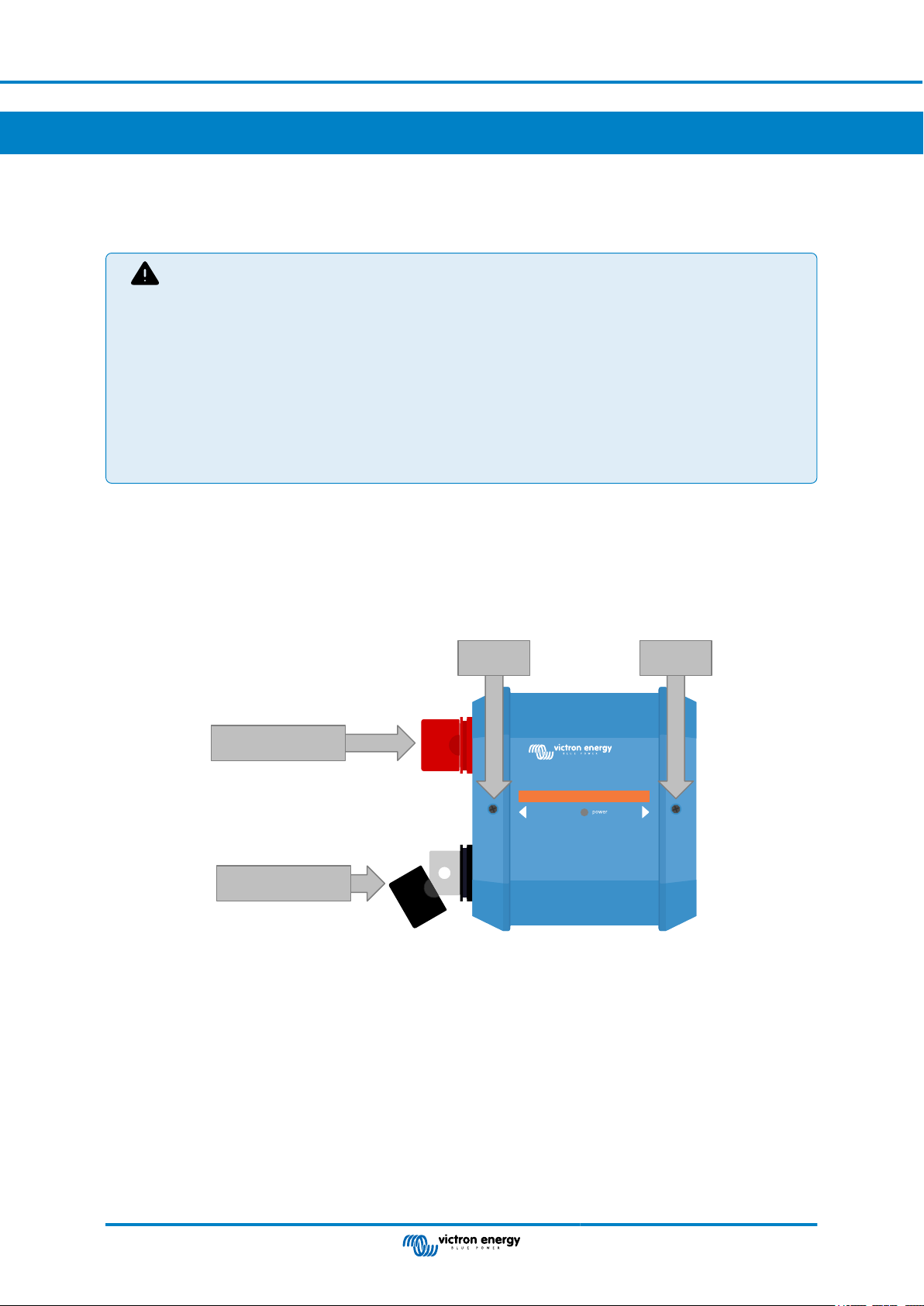

5.2. Mechanical connections .................................................................................................... 6

5.2.1. Lynx Smart BMS connection features .......................................................................... 6

5.2.2. Mounting and interconnecting Lynx modules .................................................................. 7

5.3. Electrical connections ....................................................................................................... 7

5.3.1. Connect DC wires ................................................................................................. 7

5.3.2. Connect RJ10 cable(s) ........................................................................................... 8

5.3.3. Connect BMS cables ............................................................................................. 8

5.3.4. Connect the Multi connector ..................................................................................... 9

5.3.5. Connect ATC/ATC controlled loads and chargers ............................................................. 9

5.3.6. Wiring a Remote on/off switch ................................................................................. 10

5.3.7. Programmable relay wiring ..................................................................................... 10

5.3.8. Connect the GX device ......................................................................................... 11

5.4. System examples in detail ................................................................................................ 11

5.4.1. Lynx Smart BMS, 2x Lynx Distributor and lithium batteries ................................................ 11

5.4.2. Lynx Smart BMS, 1x Lynx Distributor and lithium batteries ................................................ 12

5.4.3. Lynx Smart BMS only ........................................................................................... 13

6. Configuration and settings ....................................................................................................... 14

6.1. Power up for the first time ................................................................................................ 14

6.2. Update firmware ........................................................................................................... 14

6.3. Lynx Smart BMS settings ................................................................................................. 14

6.4. Lynx Distributor settings .................................................................................................. 16

7. Commissioning and Operation of the Lynx Smart BMS .................................................................... 18

7.1. Commissioning the Lynx Smart BMS ................................................................................... 18

7.2. Powering up ................................................................................................................ 18

7.3. BMS operating modes .................................................................................................... 20

7.4. Lynx Smart BMS trigger .................................................................................................. 21

7.5. Battery monitor operation ................................................................................................. 21

7.6. Battery care ................................................................................................................ 21

7.7. VictronConnect-Remote (VC-R) support* .............................................................................. 22

7.8. VictronConnect Bluetooth live data advertisement support* .......................................................... 22

8. Troubleshooting and Support ................................................................................................... 23

8.1. How to recover from OFF mode when no charge voltage was detected ............................................ 23

8.2. Lynx Smart BMS does not power up .................................................................................... 23

8.3. Lynx Smart BMS operational issues .................................................................................... 24

Lynx Smart BMS