IMPORTANT NOTICEBefore you proceed with fitting your Vidalux Shower please read and understand the following:

By commencing testing and installation of the unit you are agreeing to the Terms and Conditions

set out by us: copies of which are available by contacting us by by email or by telephone (details

on the cover of this manual).

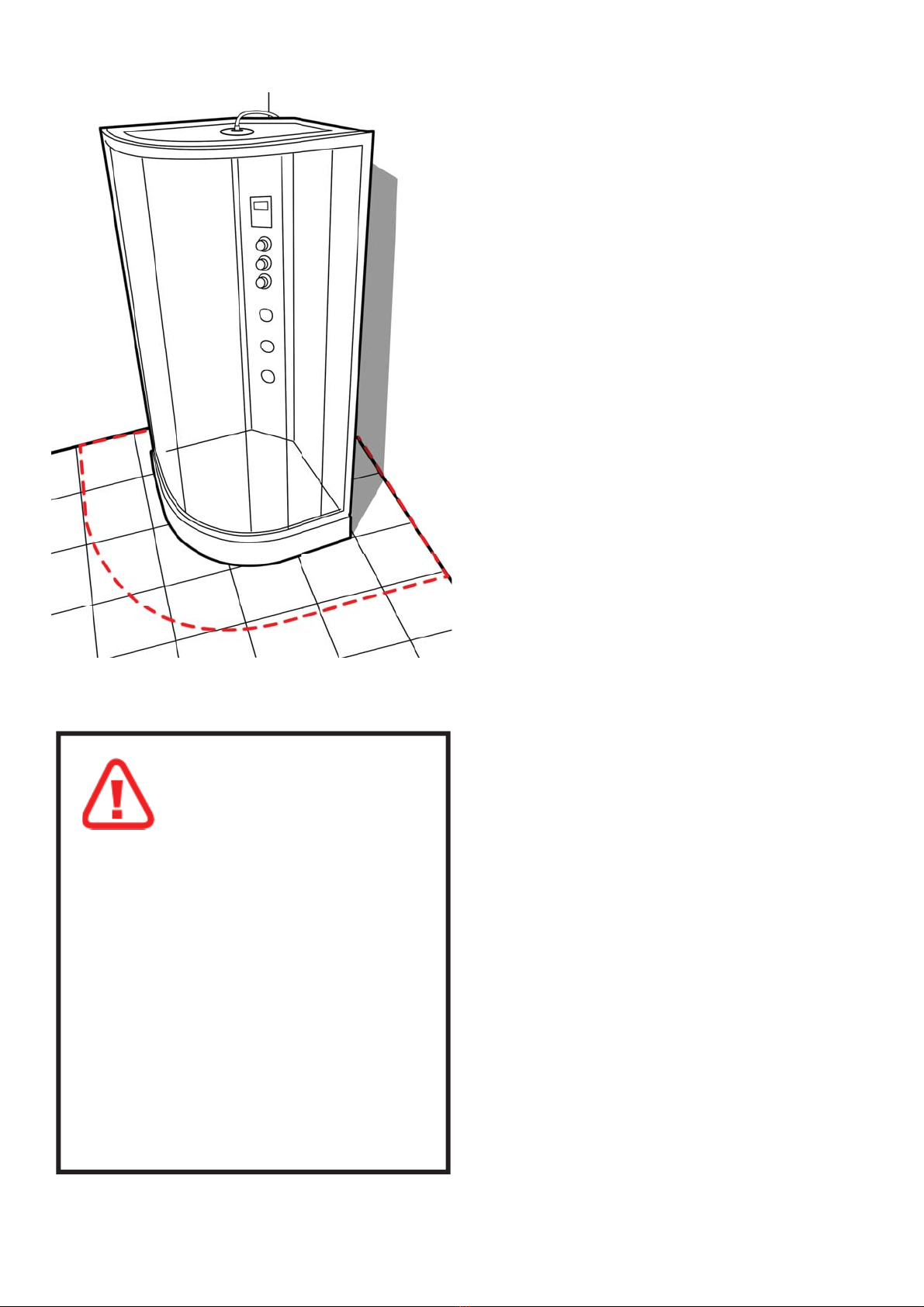

You are required to ensure the purchased product dimensions allows for ease of passage to the

intended installation area.

Regarding weight tolerances of installation area, it is advisable to contact a builder or refer to

Building regulations to ensure the product placement area has sucient joist/oor support.

1. It is important that you ensure that your purchase has been delivered undamaged. You are required to

check the contents and report any damage that you feel needs repairing or replacing within 48hrs of

receipt of goods. Items reported damaged after this time WILL be chargeable.

2. The product you have purchased is designed for home DIY fitting. You are PO MZrequired under the

Terms and Conditions to get BO ZFMFDUSJDTGFFEJO HUI FTI PX FSJO TUBMMFEby a qualified specialist. The

product requires connection toelectricity and this by law requiresa Part P qualified electrician. Failureto provide evidence of this willvoid the relating product warranty3. We are a supply only company. If you report to us any damage we will send replacements or solutions to

remedy the problem described. We endeavor to fully understand the problem rst by asking a series of

questions and then propose the solution. We may even ask for digital images to be sent via email to assist

the process. The warranty is parts only and does NOT include fitting/inconvenience or other related costs.4. You are required to ensure that you correctly water test any bath tub before fitting and ensure thatyou

ZPVSfitter fully tests the unit upon completion and attends to any leaks and faults before he leaves.

5. All hoses, such as to the valve assembly, shower outputs and air switches and waste are fittedfor

transport purposes and need to be properly sealed and tightened before use. During transportation

some connections can become dislodged and therefore break any watertight seal, you are required to

ensure that your tter specically tests for these possible occurrences and seal/xaccordingly.

6. Do not book fittJO H until you have inspected the unit. We cannot be held responsible for delays

and costs incurred by having to return to fit parts that need supplying.

7. We cannot be held liable for inconvenience caused due to lack of bathing facilities caused by any delay in

receiving your product or whilst awaiting parts.

8. Regarding our sales and technical support: We know our products and their requirements, but we are not

qualified plumbers or electricians and accept no liability for claims suggesting the same. You are advised

to check the suitability of the product with a professional body. It is the customer responsibility to ensurethe product is fit for purpose.9.A 'Completion Certificate' is included at the end of the manual where you should record the details ofyour installers - you will need this to record your warranty on our website. You MUST register theproduct warranty within 90 days following delivery3ATTENTION ALWAYS FIT EASY TO GET TO ISOLATION TAPS ON BOTH THE HOT AND COLD WATER SUPPLY (NOT SUPPLIED). JUST LIKE A DISHWASHER OR WASHING MACHINE, THIS PRODUCT MUST BE ISOLATED WHEN NOT IN USE. REMEMBER: These showers are designed to be free standing and movable from their location should you have the need to replace anything. ALWAYS USE Flexible braided water inlet pipes (not supplied) at least a metre long (not central heating plastic type!) Always use a flexible waste pipe from your house supply to the shower . NEVER FIX with rigid pipes, NEVER FIX the unit to the wall.