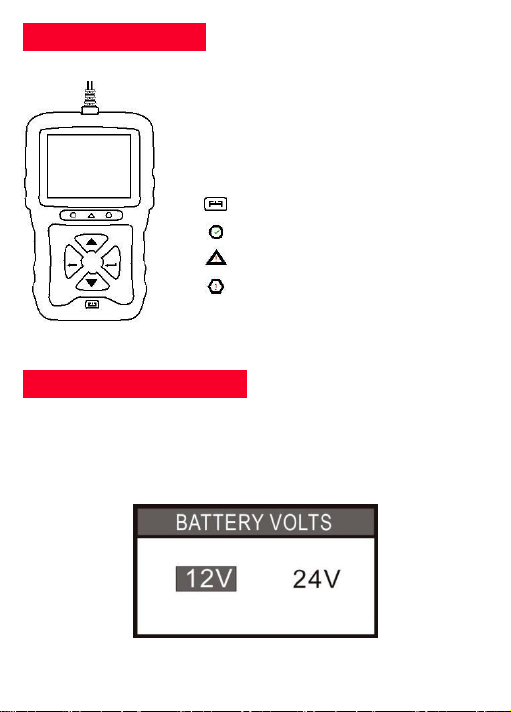

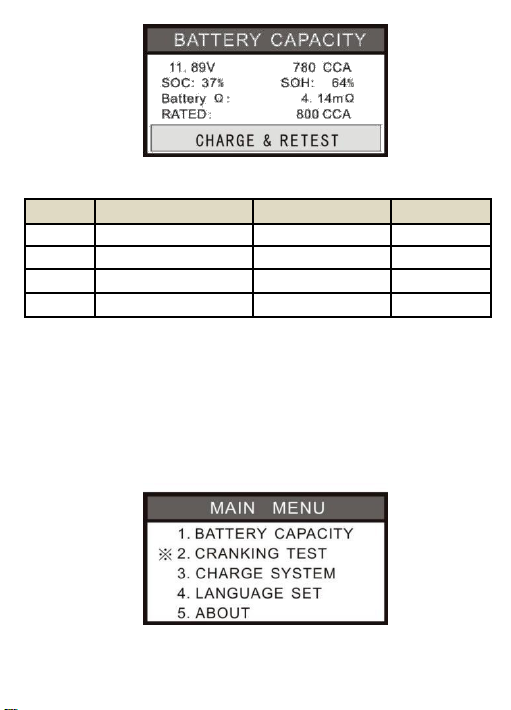

1.Brief Introduction

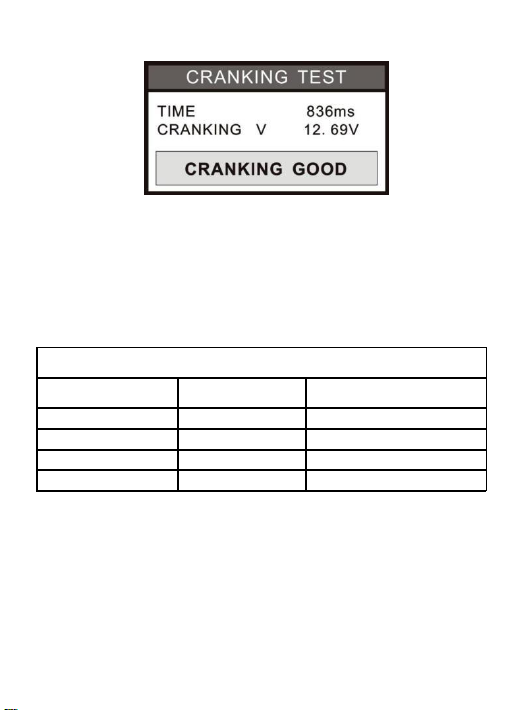

Vident iBT200 is used for lead-acid starting battery, testing the following

conditions of the battery, cranking system and charging system.

This tester supplies readings by a high resolution LCD display with great

design of easy-to-use buttons operation, intelligent test methods and

reverse polarity protection. It makes operation safe, clear and convenient.

So this is the best tool in the fields of battery sales, vehicle repair and

battery inspection in equipment system associated with lead-acid

starting battery.

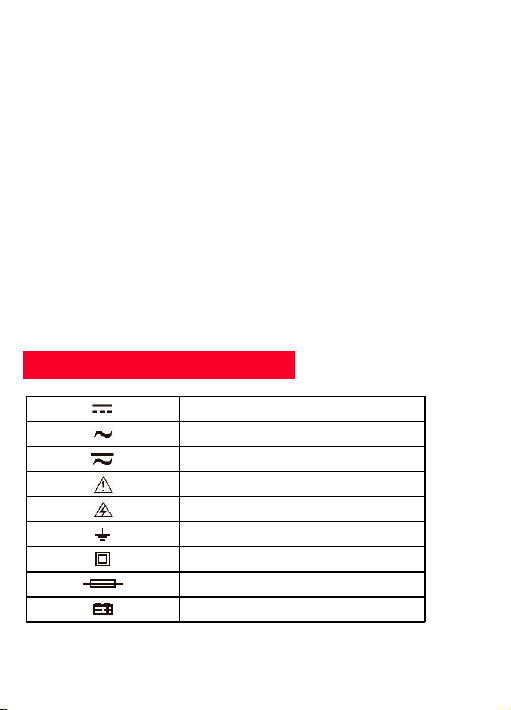

2.Safety Rules and Precautions

This manual includes instruction, operation warning and maintenance.

Damage to the meter may occur if it is not operated following the rules in

this manual. This tester is designed and produced strictly according to

IEC/EN61010-1 safety standard. Also it reaches double insulation over

voltage standard CATⅢ600V and pollution degree 2 .

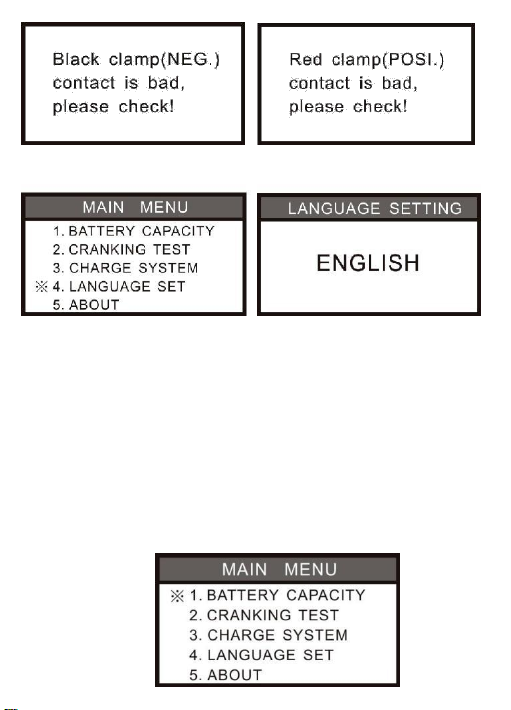

(1) Vident iBT200 is used for 12V and 24V Lead-Acid Starting Battery.

The working voltage is DC 9V to 36V.

(2) The voltage value will be higher than that in the normal situation

after the checked battery being fully charged . Please turn on the

headlights for 2 to 3 minutes, then check the battery when its voltage

drops to the normal value.

(3) Check the insulating layer of the clamps before testing. It should be

operated without any damage, bareness or disconnection. Also it is not

allowed to use it when the housing is not covered completely or correctly,

which will cause electric shock.

(4) Do not use or store the tester in the condition of high temperature, high

humidity, combustibility, explosion and strong electromagnetic field.

(5) Do not modify the internal circuit in order to avoid damage to

the tester and injury to user.

1