Instruction manual - English - EN

3MNVCWASPT_2045_EN

Contents

ENGLISH 1

1 About this manual ....................................................................................................................5

1.1 Typographical conventions ................................................................................................................................................ 5

2 Notes on copyright and information on trademarks.............................................................5

3 Safety rules................................................................................................................................5

4 Product description and type designation.............................................................................6

4.1 Product marking label.......................................................................................................................................................... 6

5 Preparing the product for use .................................................................................................6

5.1 Unpacking................................................................................................................................................................................. 6

5.2 Contents .................................................................................................................................................................................... 6

5.3 Opening of the 30m delivery head pump casing....................................................................................................... 6

5.4 Safely disposing of packaging material ......................................................................................................................... 6

6 Installation ................................................................................................................................7

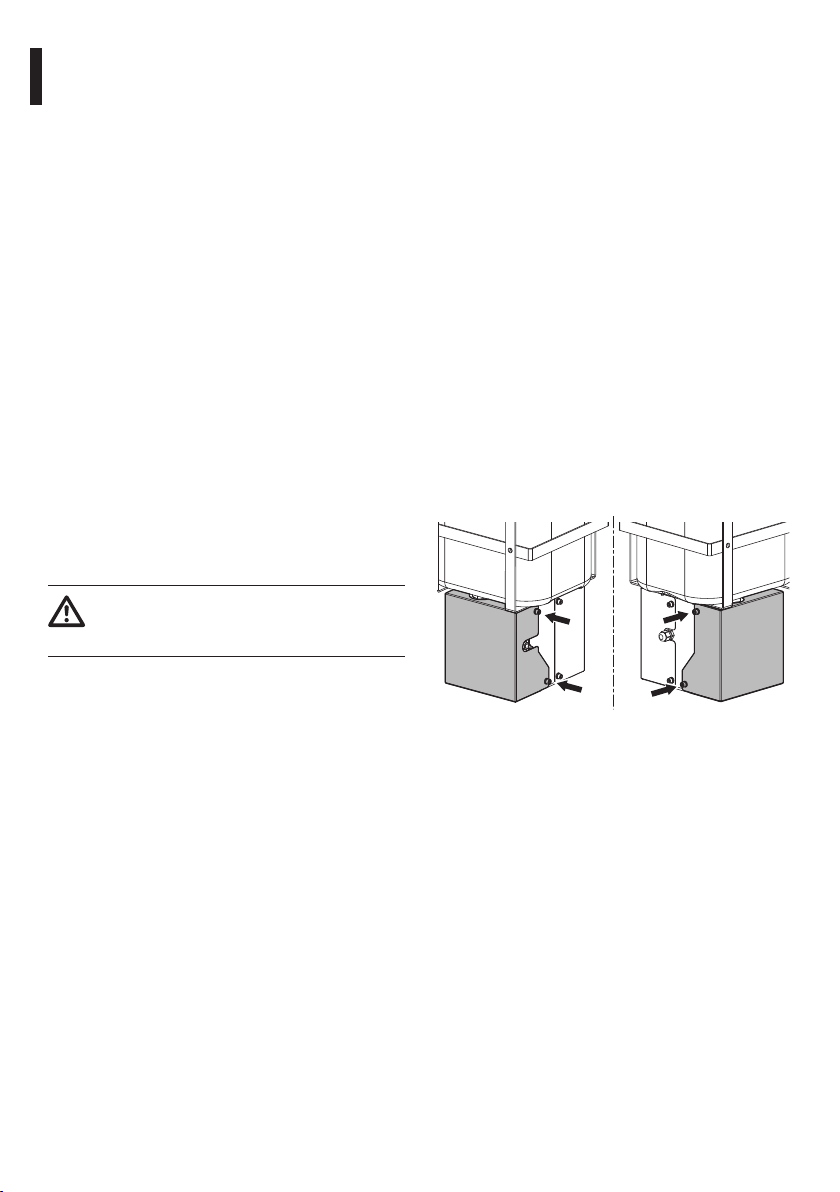

6.1 Fastening of the metal cage............................................................................................................................................... 7

6.2 Choosing the power supply ............................................................................................................................................... 8

6.3 Open the box........................................................................................................................................................................... 8

6.4 Board description................................................................................................................................................................... 8

6.5 Connection of the board ..................................................................................................................................................... 9

6.5.1 Installing the fuse .................................................................................................................................................................................... 9

6.5.2 Connection of the PTZ camera or stand-alone housing............................................................................................................ 9

6.5.3 Pump manual activation.....................................................................................................................................................................11

6.5.4 Wiper connection ..................................................................................................................................................................................11

6.5.5 Wiper manual activation.....................................................................................................................................................................11

6.5.6 Remote control with DTWRX optional board..............................................................................................................................11

6.5.7 Connection of the power supply line.............................................................................................................................................12

6.6 Pump installation .................................................................................................................................................................12

6.6.1 Adjustment of the level switch position........................................................................................................................................12

6.6.2 Pump with 5m (16ft) delivery............................................................................................................................................................13

6.6.3 Pump with 11m (36ft) delivery .........................................................................................................................................................13

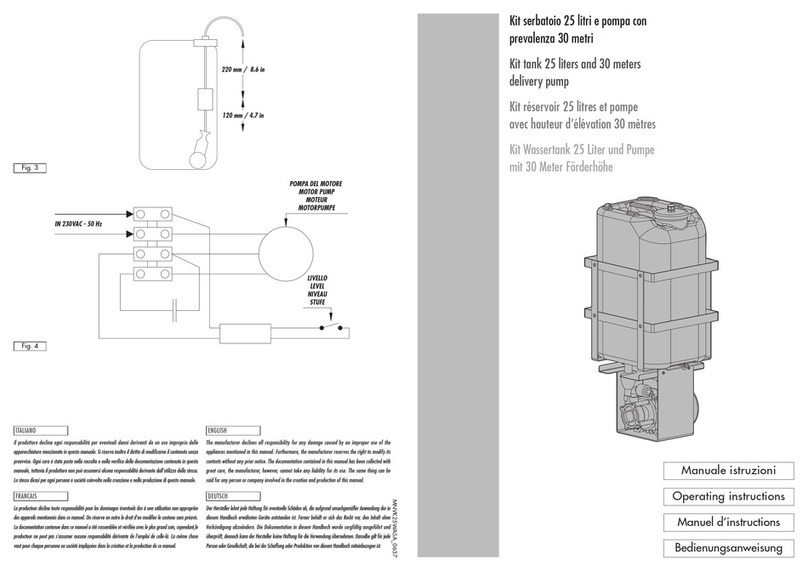

6.6.4 Pump with 30m (98ft) delivery .........................................................................................................................................................13

6.7 Washer installation (ULISSE range) ................................................................................................................................14

7 Washer installation (ULISSE2)................................................................................................15

7.1 Washer installation (ULISSE COMPACT range) ...........................................................................................................16

7.2 Washer installation (ULISSE EVO range).......................................................................................................................16

7.2.1 Washer installation on the PTZ camera .........................................................................................................................................16

7.2.2 Washer installation on the overturned PTZ camera..................................................................................................................17

7.3 Washer installation (NVX range)......................................................................................................................................18

7.4 Washer installation (NXPTZ SERIES2 range)................................................................................................................19

7.5 Examples of washer installation......................................................................................................................................20

8 Maintenance ...........................................................................................................................21

8.1 Extraordinary maintenance (to be done only under particular circumstances) ...........................................21

8.1.1 Fuses replacement.................................................................................................................................................................................21

8.1.1.1 Replacing the fuse of the pump board.................................................................................................................................................................21