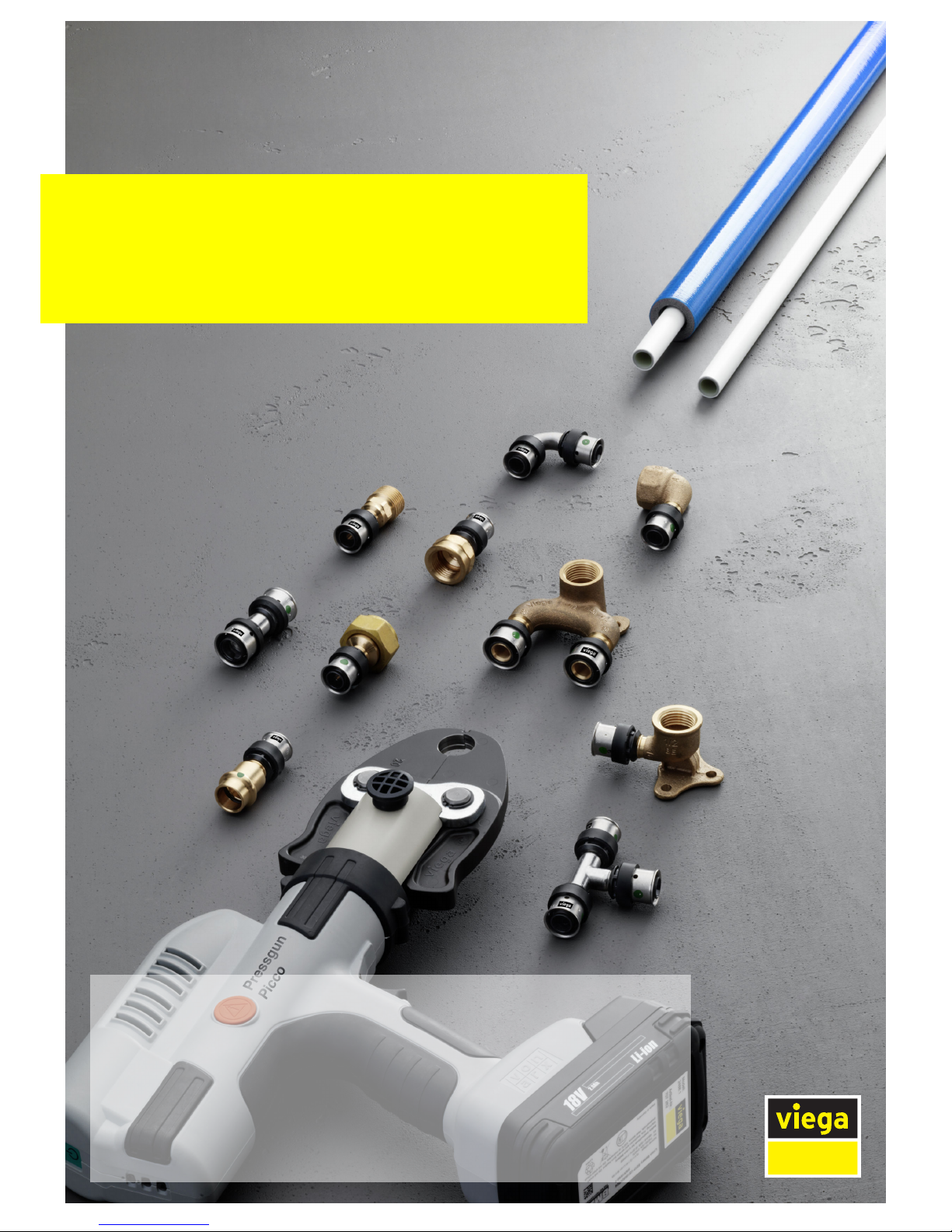

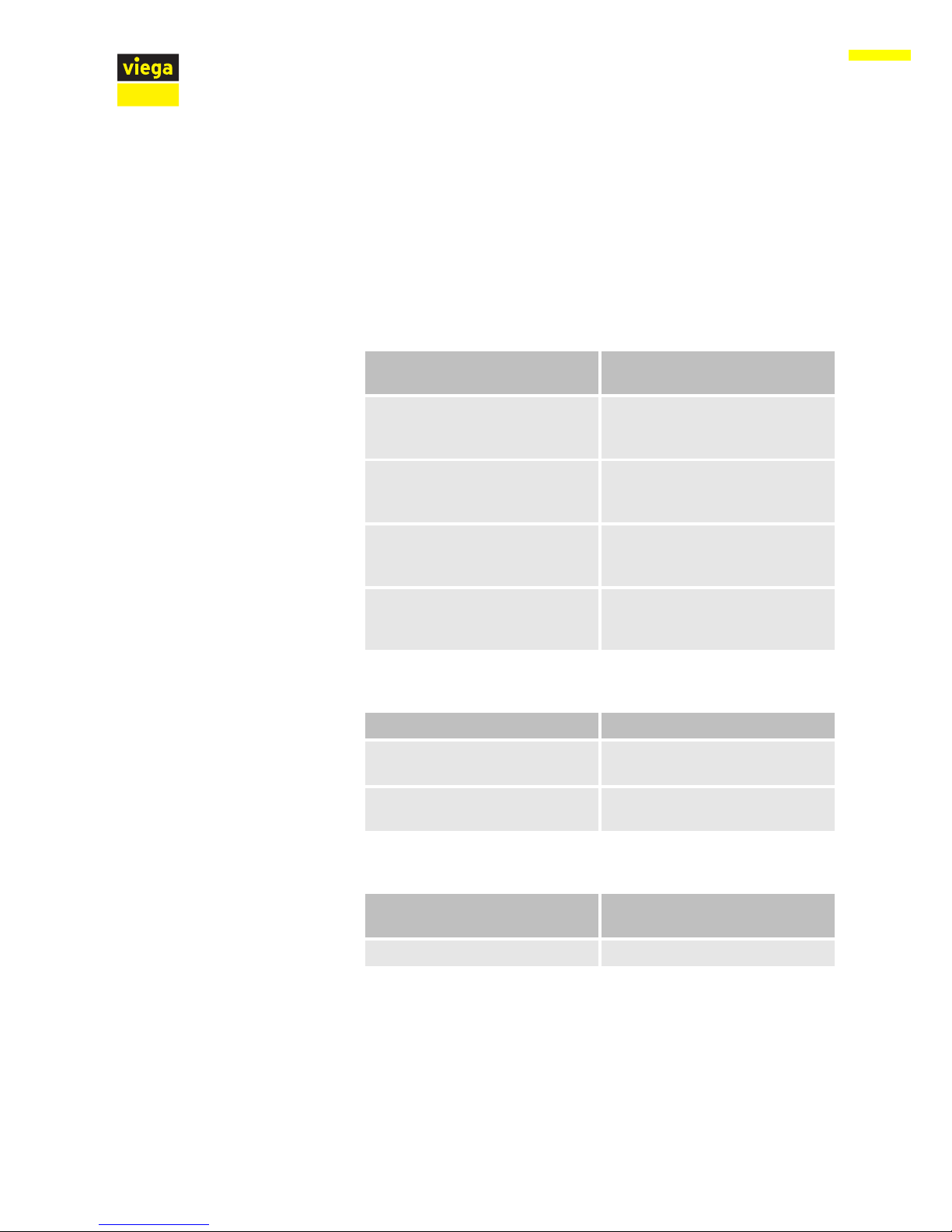

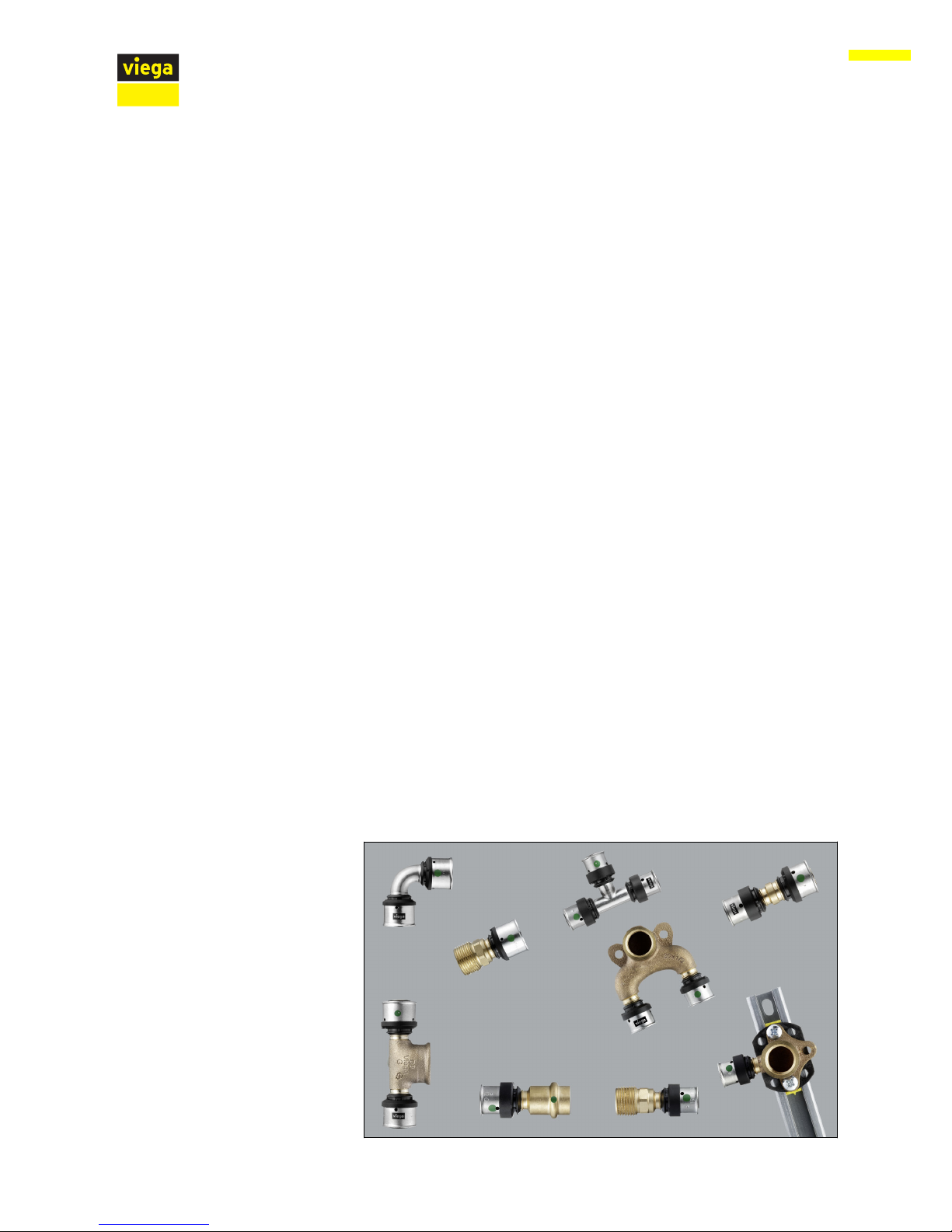

The system components are available in the following dimensions:

d 16 / 20 / 25 / 32 / 40 / 50 / 63.

2.3.2 Pipes

The following pipes are available from the system described:

Viega Smartpress multilayer pipes, with or without protective pipe, with

various thicknesses of insulation are available in coiled bundles. Dimen‐

sionally stable multilayer pipes are also available in 5 m lengths. The fol‐

lowing pipes are available from the system described:

Viega Smartpress-PE-Xc/Al/PE-Xc

dimensionally stable

with external oxygen seal coat

d 16, 20, 25, 32, 40, 50, 63

Viega Smartpress-PE-Xc/Al/PE-Xc

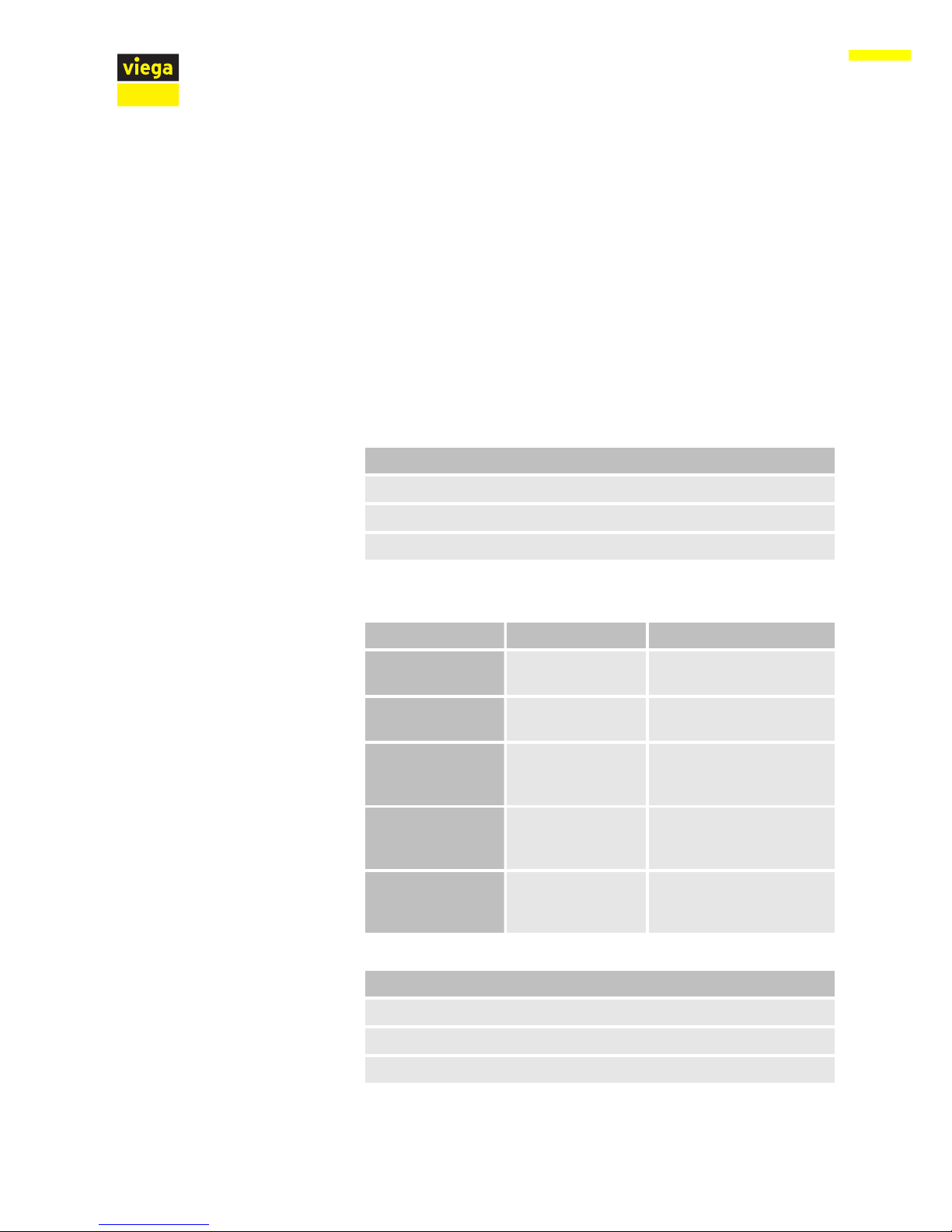

Type of pipe d Areas of use

Pipe in rods 16, 20, 25, 32, 40,

50, 63

Drinking water and heating

installations

Pipe without pro‐

tective pipe

16, 20, 25, 32 Drinking water and heating

installations

Pipe with protective

pipe (black, blue,

red)

16, 20, 25 Drinking water and heating

installations

Pipe with 6 mm

surrounding insula‐

tion (blue)

16, 20 Drinking water and heating

installations

Pipe with 9 mm

surrounding insula‐

tion (blue)

25 Drinking water and heating

installations

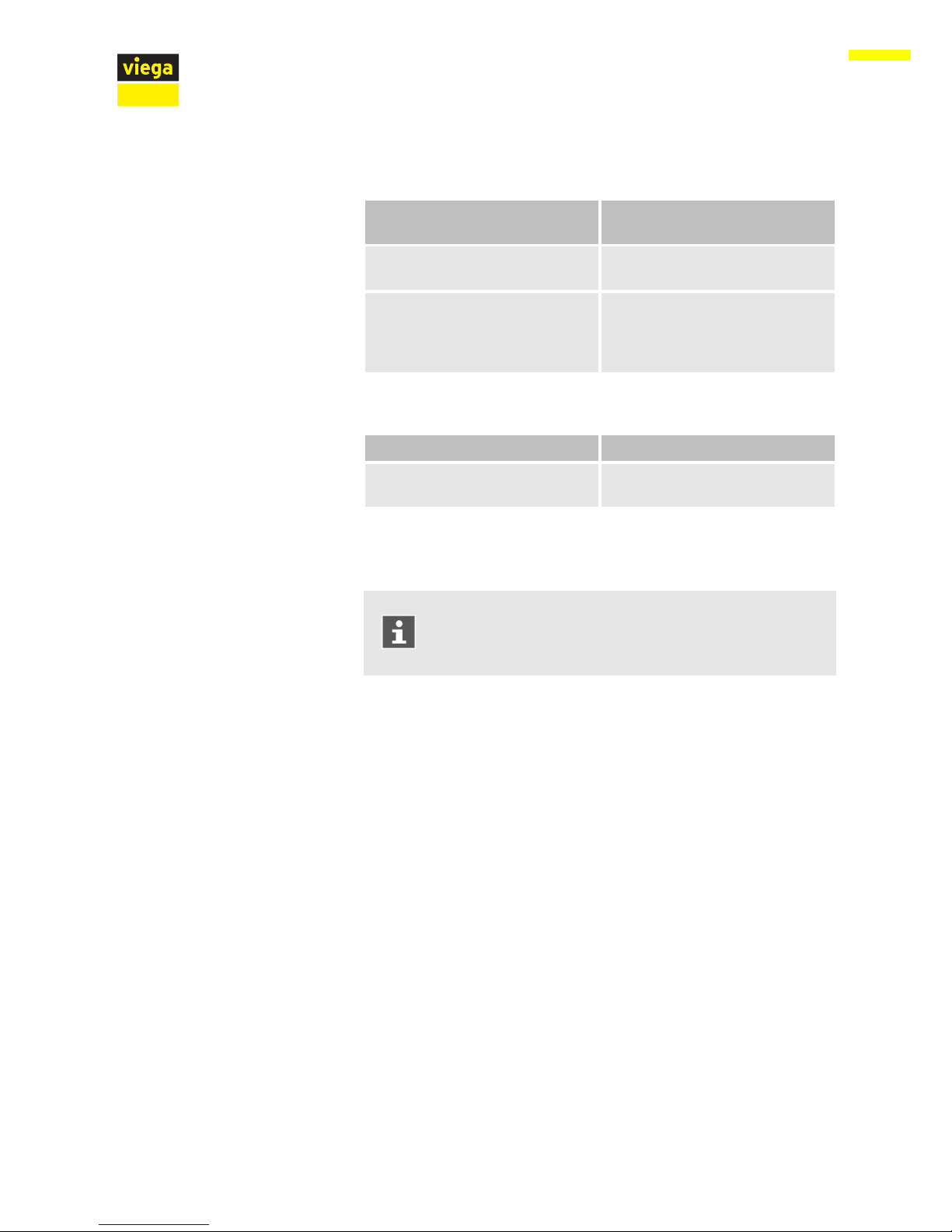

Viega Smartpress PERT/Al/PERT

dimensionally stable

with external oxygen seal coat

d 16, 20

Product information

Viega Smartpress 9 from 23