Contact

PELA Tools

Solängsvägen 13

SE-513 70 Borås

Telefon: 033-202650

Environmental protection/

Scrapping

Recycle any unwanted material, do not

throw it in the household rubbish. All

machines, accessories and packaging

must be sorted and left at a recycling center and

disposed of in an environmentally friendly

manner.

Specifications

Bending capacity: Bends material with a

maximum thickness of 1.4 mm up to 90 degrees.

Bends materials up to 750 mm wide. Designed to

be mounted on a workbench. Use 4 pieces of 10

mm bolts to attach it to the worktop.

Dimensions.....................L 876 x W 152 x H 73mm

Weight...........................................................13.2 kg

Save this manual

Keep the manual as you may need it for

maintenance procedures, parts list and diagram.

Keep your invoice together with this manual.

Write the invoice number on the inside of the

front page. Keep the manual and invoice in a safe

and dry place for future use.

Safety and precautions

WARNING: Basic safety precautions should

always be followed when using the tool to reduce

the risk of injury to persons and others injuries.

Read all instructions before using this product!

• Keep the work surface clean.

• Observe the conditions in the work area. Do

not use machines or power tools in damp or

wet locations. Do not expose to rain. Keep

the work area properly lit. Do not use power

tools in the presence of ammable gases or

liquids.

• Keep children away. Children should never

be allowed in the work area. Do not allow

them to handle machinery, tools or extension

cords.

• Store equipment that is not in use. When not

in use, tools should be stored in a dry place

to prevent them from rusting. Always lock up

tools and keep away from children.

• Do not force the tool. It will make the job

better and safer in the capacity it was

intended for. Do not use inappropriate

accessories in an attempt to exceed the tool’s

capabilities.

• Use the right tool for the job. Don not try to

make a small tool or accessory do the job of

a larger industrial tool. Do not modify this tool

or use it for a purpose for which it was not

intended.

• Dress appropriately. Do not wear loose

clothing or jewelry, as they can get caught in

moving parts. Protective, electrically non-

conductive clothing and non-slip shoes are

recommended during work. Wear hair

protection to keep long hair out.

• Be alert. Watch what you’re doing and use

common sense. Do not use tools when you

are tired.

• Spare parts and accessories. Use only

identical spare parts when servicing. Using

other parts will void the warranty. Use only

accessories intended for use with this tool.

• Maintenance. For your safety, service and

maintenance should be done regularly by a

qualied technician.

WARNING: Warnings, precautions and

instructions in this user manual cannot cover

all possible conditions and situations that may

arise. The operator should understand that

common sense and caution are factors that

cannot be built into the product, but must come

from the operator itself.

Installation and operating instructions

Install the bending tool as described below to

prevent injuries and accidents.

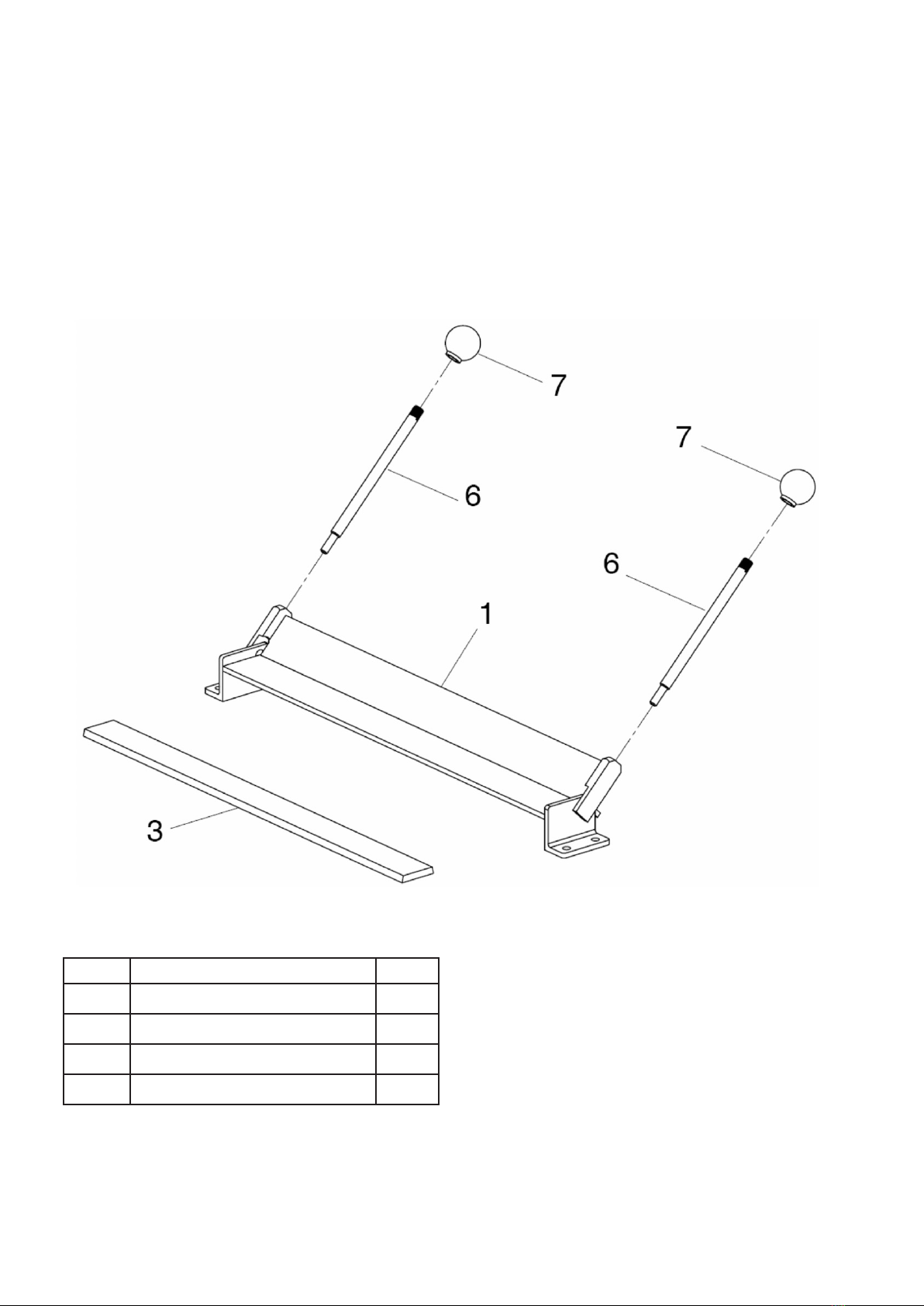

1. The bottom plate #1 must be attached to

a workbench with four 10 mm bolts in the

mounting holes.

2. Each handle ball (#07) mounts on the rods

(#06) and the rods must be placed in the

xings in the bottom plate.(#01). The handles

are not intended to sit permanently mounted

in the brackets i the bottom plate (#01).

3. To use the bending tool, lower the handles

(#06) until the moving part of the base plate

(#01) is parallel to the workbench. Place the

material to be bent between the xed part

of the tool (#01) and the moving part of the

tool (#01 ) and align them with the edge to be

bent towards the back edge (#01).

4. Place and attach the press piece (#3) on top

of the xed part of the tool (#1) in line with

the back edge of the xed part (#1).

Note: To get a good bend, you should leave

a gap of 3 mm for material of 1.2 mm. For

thicker materials, the gap should be large. We

suggest you try and bend scrap pieces rst to

make sure you place the material correctly.

We recommend that you tighten the material

with clamps or similar tools.