2.2.1 Areas of use

The system is intended for use in industrial and heating systems and is

a replacement for welded and threaded connections in new installations

and repairs. The system is not suitable for use in drinking water installa-

tions. For this reason, pipes and connectors are labelled with a black

symbol "Not drinking water".

Do not use the piping system for fuel gas, see

Ä„Regulations from sec-

tion: Fields of application“ on page 6

.

Use is possible in the following areas among others:

nIndustrial and heating systems

nSprinkler systems

nFire extinguishing systems, see

Ä„Regulations from section: Fields

of application“ on page 6

nCompressed air systems

nCooling water pipelines (closed circuit)

nSystems for technical gases (on request)

2.2.2 Media

The system is suitable for the following media, amongst others:

For the applicable directives, see

Ä„Regulations from section:

Media“ on page 6

.

nHeating water for closed pump hot water heating systems

nCompressed air (dry) in compliance with the specification of the

sealing elements being used

– EPDM at oil concentration < 25 mg/m3

nAnti-freeze, cooling brines up to a concentration of 50 %

ntechnical gases (on request)

2.3 Product description

2.3.1 Overview

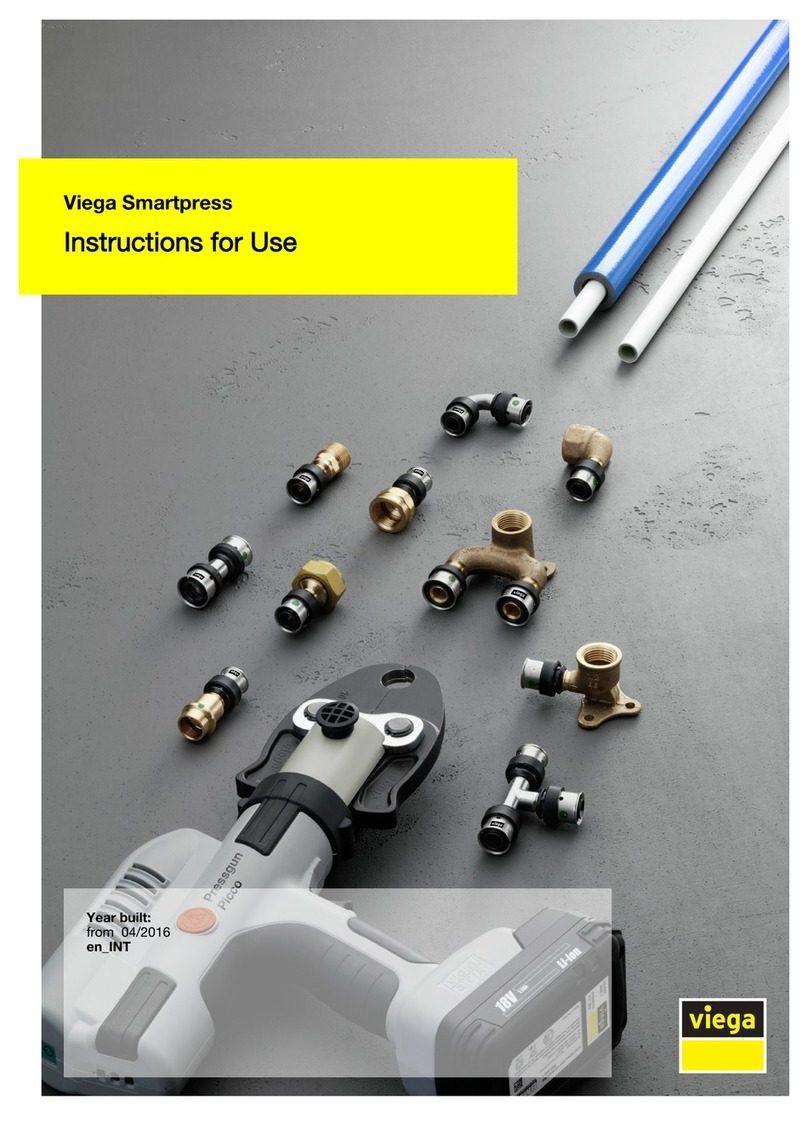

The piping system consists of press connectors for thick-walled steel

pipes and the corresponding press tools.

Fig. 1: "Not drinking water"

Product information

Megapress 8 from 32