6

The appliance is only intended to be installed and

operated in ventilation systems that comply with

EN 1946-6, with due attention paid to the associated

installation, service and operating instructions. It is

only designed for the controlled mechanical ventilation

of living spaces.

Intended use presupposes that a fixed installation in

conjunction with permissible, system-specific compo-

nents has been carried out.

Commercial or industrial usage for a purpose other

than mechanical ventilation of living spaces shall be

deemed inappropriate.

Any usage beyond this must be approved by the man-

ufacturer for the individual case.

Incorrect usage or operation of the appliance (e.g. the

appliance being opened by the system user) is prohibi-

ted and results in an exclusion of liability. Incorrect

usage also occurs if the components in the ventilation

system are modified from their intended function.

Note

The appliance is intended exclusively for domestic

use, i.e. even users who have not had any instruction

are able to operate the appliance safely.

Passive house use

Vitovent 300-W meets the requirements for passive

house use.

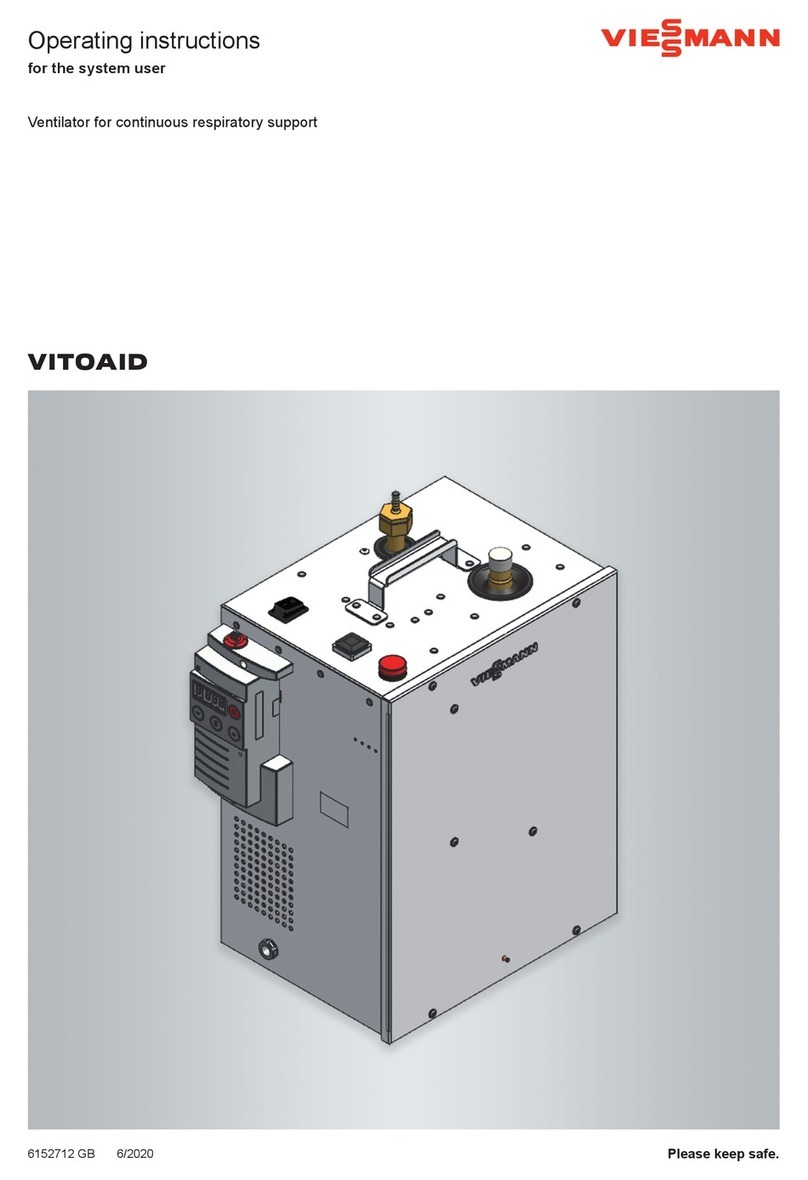

Product information

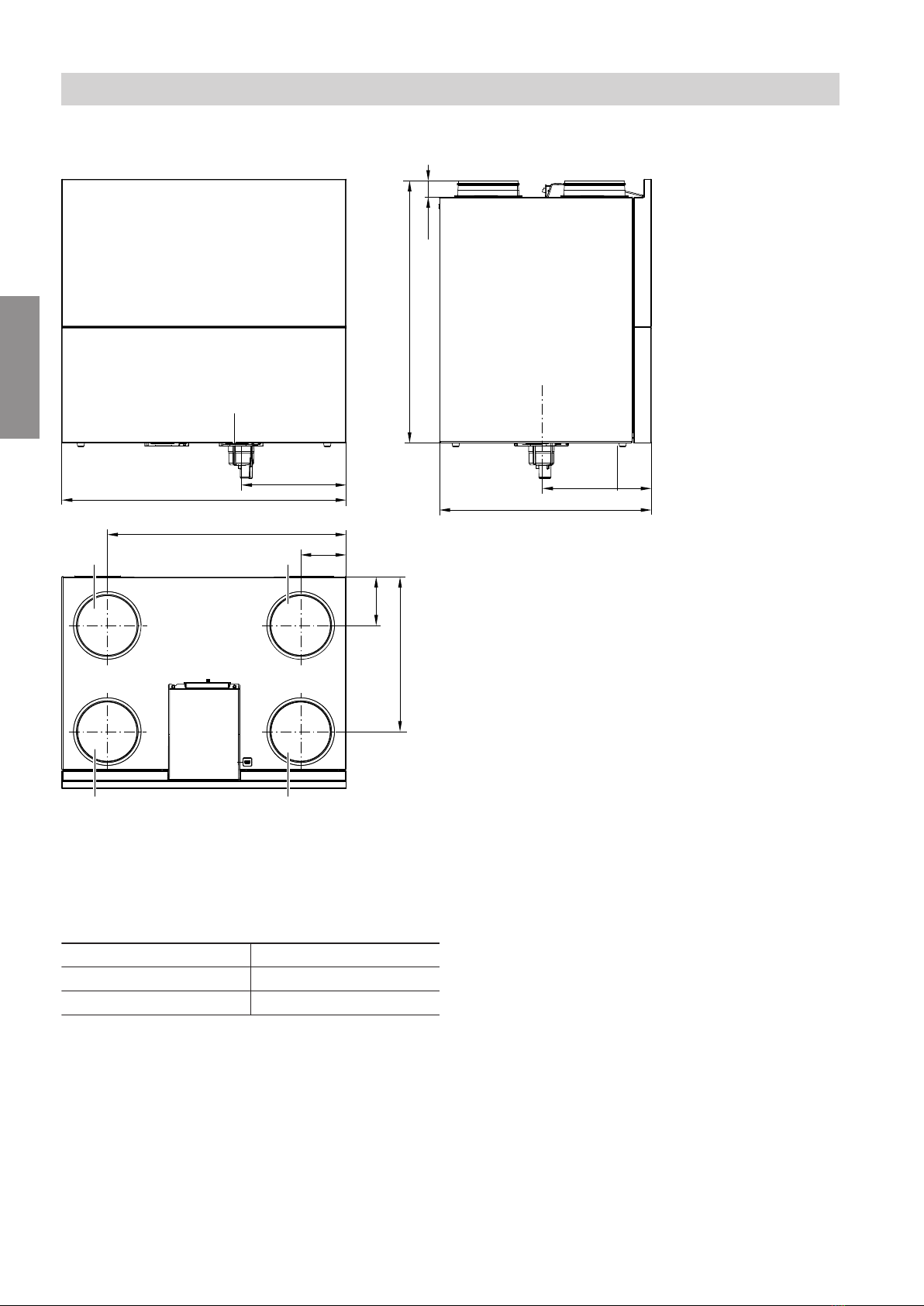

The Vitovent 300-W is a mechanical ventilation unit for

detached houses or apartments with up to 440 m2 of

living space. The Vitovent 300-W is available in left or

right-hand versions. In the left-hand version, the supply

air and extract air connections are on the left side of

the unit. In the right-hand version, these connections

are on the right side of the unit.

The ventilation unit is operated using the ventilation

programming unit, type LB1, or the "Vitotronic 200 con-

trol unit, type WO1C", of a Viessmann heat pump.

When fresh outdoor air is drawn into the ventilation

unit, it is first passed through a filter. The outdoor air is

then preheated in the countercurrent heat exchanger

by the energy from the extract air, without the two air

flows mixing. The cleaned and preheated outdoor air is

then routed through the ductwork as supply air to the

rooms.

The extract air is drawn out of rooms where moisture

and odours are created (kitchen, bathroom, WC) and

then transported to the ventilation unit via the duct-

work. There, the extract air is purified by means of a fil-

ter to protect the countercurrent heat exchanger. At the

heat exchanger, the extract air preheats the cooler out-

door air according to the countercurrent principle and

is then routed out of the building via the exhaust air

duct.

Heat recovery is switched off automatically in line with

the temperatures inside and outside the building. This

is achieved by closing the bypass damper. This ena-

bles the inside of the building to be cooled by the out-

door air, e.g. on cooler summer nights.

The constant flow rate control ensures a defined, con-

stant air flow rate on the supply and extract air side,

irrespective of the static pressure of the ductwork. The

built-in preheating coil ensures balanced operation

even at outside temperatures down to about –10 °C

and so ensures a consistently high heat recovery level.

For operation below this temperature, an additional

electric preheating coil (accessories) can be built into

the outdoor air duct.

Time programs can be set on the programming unit of

the heat generator or ventilation unit to match the

mechanical ventilation system to demands.

The ventilation unit must always remain switched on to

expel any moisture.

Shutting down the system creates a risk of condensa-

tion forming inside the ventilation unit and on the build-

ing structure (moisture damage).

The ventilation unit has active monitoring of the instal-

led supply air and extract air filters. Required filter

changes are indicated on the respective programming

unit and can therefore be carried out as necessary.

Information

Intended use

6152162

Information