8

Installation requirements

■Preferably site the ventilation unit inside the airtight

and thermally insulated building envelope.

!Please note

The installation room must be dry and free

from the risk of frost.

Ensure ambient temperatures between 2 and

35 °C.

■The ventilation unit can be installed on the ceiling or

wall mounted.

■Keep ductwork to the extract air and, where appro-

priate, supply air areas short.

■Thermally insulated supply air and extract air pipes

that are routed through unheated areas of the build-

ing in accordance with DIN 1946-6 (not applicable to

EPP pipes or bends).

■A standard socket is required for the power supply.

■Connect the condensate drain to a waste water pipe.

■The ventilation unit must be accessible for mainte-

nance purposes.

Possible installation sites:

■Separate plant room, storage area or utility room on

the ground floor

■Cellar

■Thermally insulated long pane attic room

Open flue combustion equipment and Vitovent

Danger

The simultaneous operation of open flue com-

bustion equipment (e.g. an open fireplace) and

the Vitovent in a space with combustion air inter-

connection results in dangerous negative pres-

sure in the interior. Negative pressure can result

in flue gas re-entering the room.

In order to prevent health risks, observe the fol-

lowing:

■Never operate the Vitovent simultaneously with

open flue combustion equipment (e.g. open fire-

place).

■Only operate combustion equipment in room sealed

mode with a separate combustion air supply. We rec-

ommend combustion equipment that has general

building approval as room sealed combustion equip-

ment of the Deutsches Institut für Bautechnik (DIBt)

[Germany].

■Keep doors to boiler rooms that are not part of the

combustion air interconnection with the living space

airtight and shut.

Information regarding the operation of the Vitovent

in conjunction with open flue combustion equip-

ment

■On-site safety equipment must be installed that will

switch off the ventilation unit when there is negative

pressure inside the room.

■The relevant flue gas inspector must give his/her

approval [check local regulations].

■Frost protection for the countercurrent heat

exchanger is ensured by means of the integral pre-

heater coil. For operation with even lower outside

temperatures, provide an additional external electric

preheater coil (accessories) or a geothermal heat

exchanger (on site) in the outdoor air duct.

Extractor hoods, extracting tumble dryers and the

Vitovent

!Please note

The simultaneous operation of extractor hoods

or extracting tumble dryers and the ventilation

unit in interconnected rooms results in negative

pressure inside the room.

Never link extractor hoods or extracting tumble

dryers into the ventilation unit ductwork.

Set up kitchen extractor hoods as recirculating

extractors, which is more energy efficient.

Never connect existing extractor hoods to the extract

air duct of the mechanical ventilation system for the

following reasons:

■Hygiene, contamination:

grease deposits in the extract air system

■Noise from the supply air valves:

Extractor hoods operate with a substantially greater

air flow rate (> 300 m3/h) than the ventilation unit.

The generated negative pressure creates a "short

circuit" inside the system, as the amount of differen-

tial air must be made up by the ventilation ductwork.

Connect extractor hoods via a coaxial exhaust air sys-

tem to enable the differential air volume to be replen-

ished.

Provide an interlock for the extractor when using an

extractor hood in conjunction with open flue combus-

tion equipment: See chapter "Open flue combustion

equipment and Vitovent"

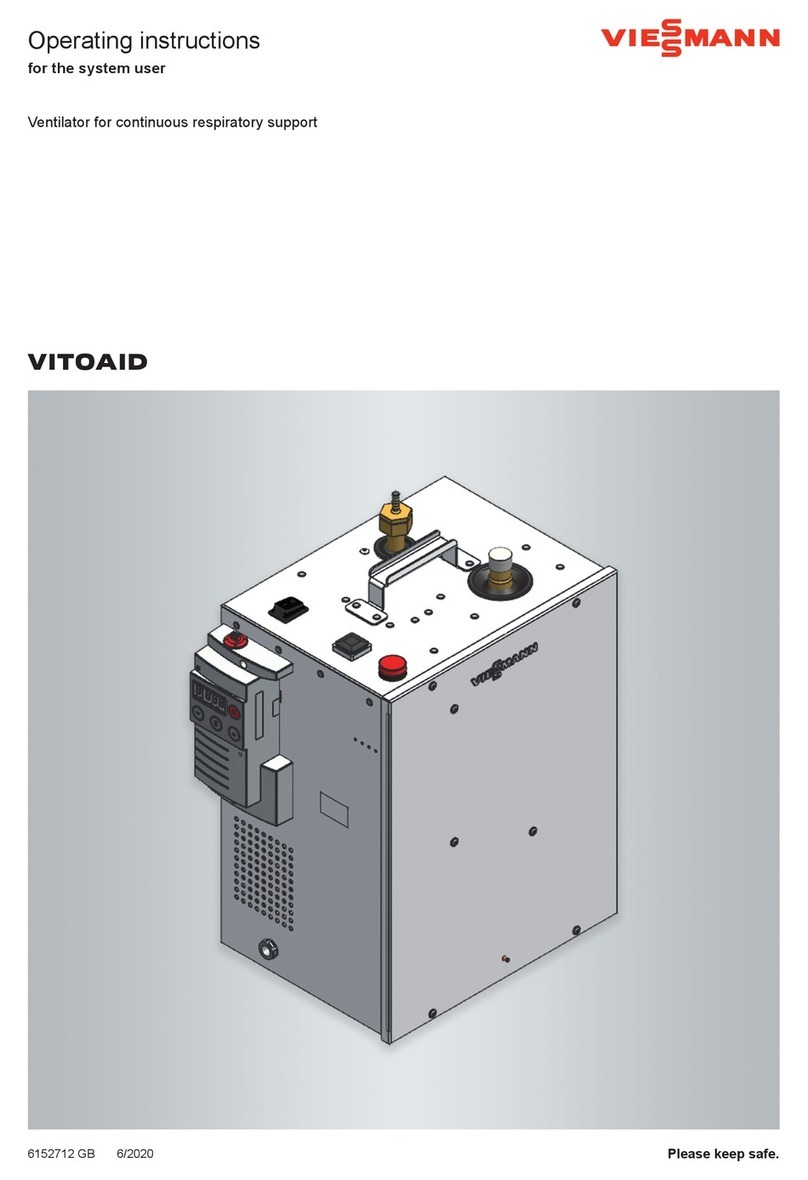

Preparing for installation

Siting

5816563

Installation