Installation Manual 799030, Revision E, 03/12 Page i

Table of Contents

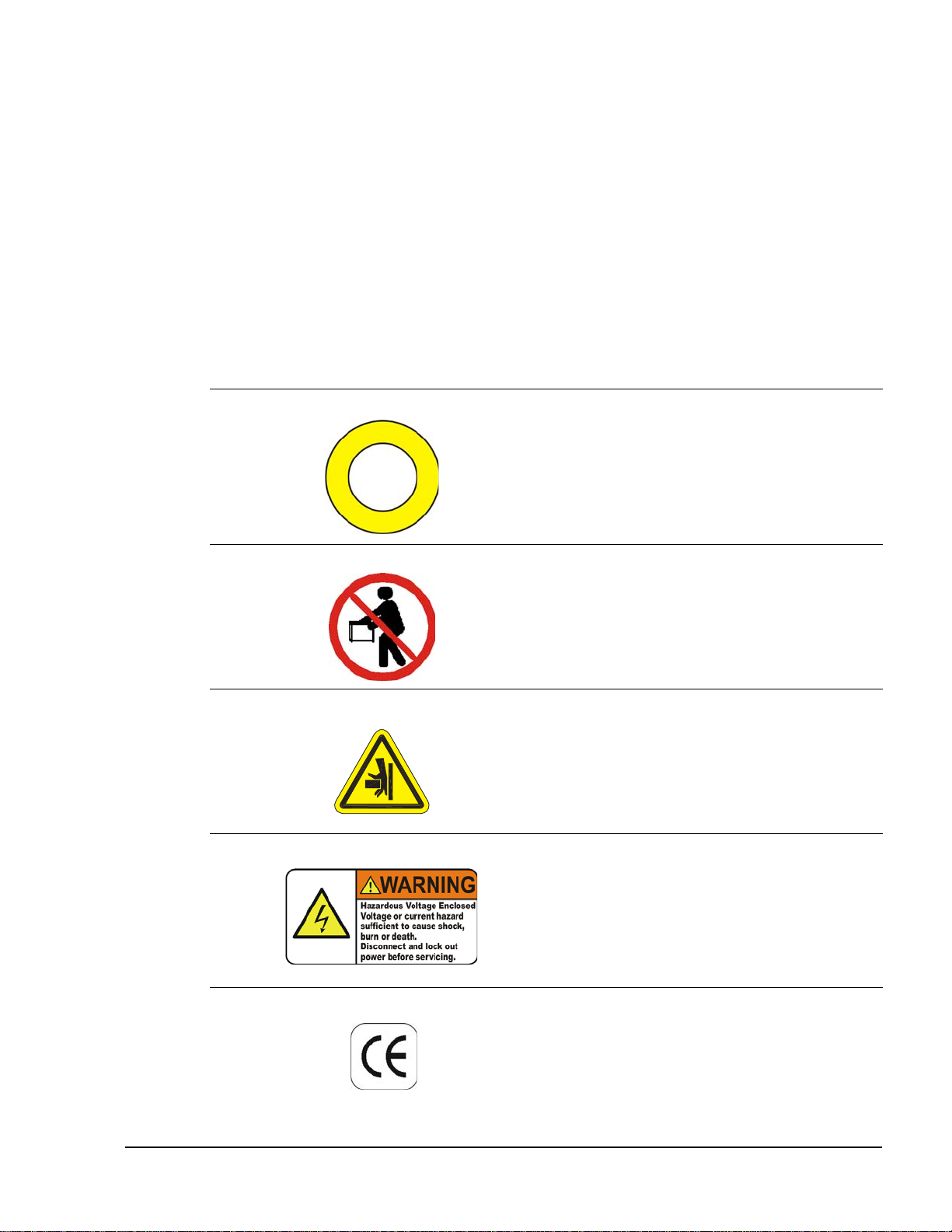

Important System Labels iii

1 About This Manual 1

1.1 What This Chapter Contains 1

1.2 Who Should Read This Manual 1

1.3 Required Knowledge 1

1.4 What This Manual Contains 1

1.5 Where to Get Help 2

2 System Overview 3

2.1 What This Chapter Contains 3

2.2 What Is Benchmark 250? 3

2.3 System Components 4

2.4 How the System Operates 5

3 Safety Information 7

3.1 What This Chapter Contains 7

3.2 Emergency Stop 7

3.3 System Status LEDs 8

3.4 System Power 9

3.5 System Lockout 10

3.6 Safety Guidelines 11

4 Installation 13

4.1 What This Chapter Contains 13

4.2 Choosing an Installation Site 14

4.3 Unpacking the Machine 15

4.4 Removing the X, Y, and Z Restraints 19

4.5 Installing the Stage Glass 23

4.6 Arranging and Connecting the System 24