2 / 4 P/N 3102074-EN • REV 02 • ISS 09MAY13

CO sources

The CO sensor in this detector is designed to detect carbon

monoxide gas from any source of combustion. It is not

intended to detect fire, smoke, or any other gas. Potential CO

sources include fuel-fired appliances (e.g., space heater,

furnace, water heater, range, oven, clothes dryer); other

sources of combustion (e.g., kerosene-burning stove or heater,

or gas log fireplace); or internal combustion engines.

In addition, excessive exhaust spillage or reverse venting of

fuel-burning appliances can produce dangerous transient

levels of CO. This can be caused by external conditions:

•Wind direction, velocity, or a combination of both,

including high gusts of wind or insufficient draft in vent

pipes

•Temperature inversions that can trap exhaust gases near

the ground

•Negative pressure differential resulting from the use of

exhaust fans

•Simultaneous operation of several fuel-burning appliances

competing for limited internal air

•Vent pipe connections vibrating loose from dryers,

furnaces, or water heaters

•Obstructions in vent pipes or unconventional vent pipe

designs which can amplify the above situations

•Poorly designed or maintained chimneys and/or vents

•Extended operation of unvented fossil fuel-burning devices

(range, oven, fireplace, etc.)

•Idling cars in an open or closed attached garage, or near

the premises

General limitations of CO detectors

This detector is designed to protect individuals from the acute

effects of CO exposure. It will not fully safeguard individuals

with specific medical conditions. People with special medical

problems should consider using specialized detection devices

with less than 30 ppm (parts per million) alarming capabilities.

If in doubt, consult a medical practitioner.

If the unit is in trouble or at the end of its life, it may not sense

CO and cannot be relied upon to monitor CO levels. Replace

the CO module every six years from the date of manufacture or

when the control panel indicates a sensor end-of-life condition,

whichever comes first.

A detector installed outside a bedroom may not awaken a

sleeper. Normal noise due to stereos, television, etc. may also

prevent the detector from being heard if distance or closed or

partly closed doors muffle the sounder. This unit is not

designed for the hearing impaired.

CO detectors are not a substitute for life safety. Though these

detectors will warn against increasing CO levels, we do not

warrant or imply in any way that they will protect lives from CO

poisoning. They should only be considered as an integral part

of a comprehensive safety program.

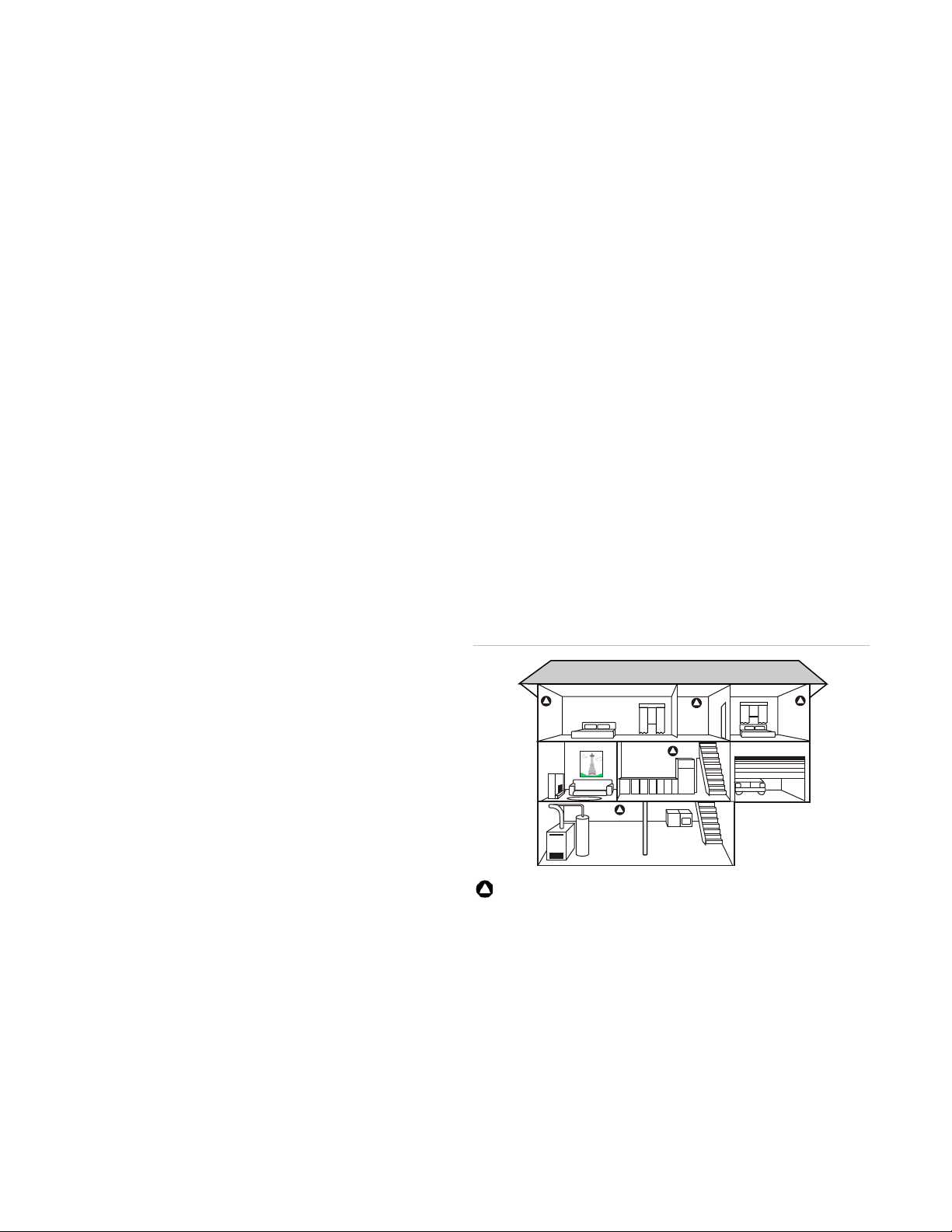

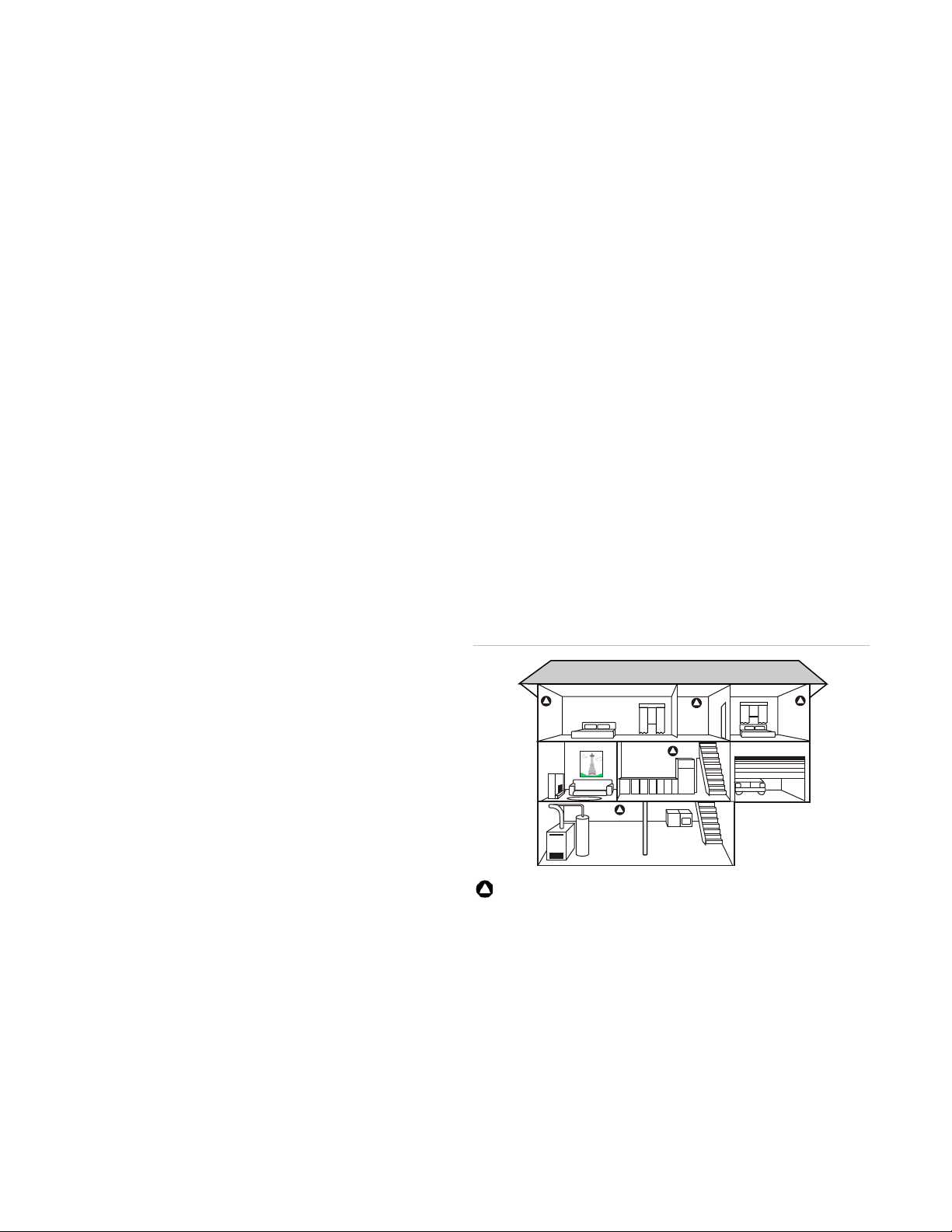

Detector locations

Selecting a suitable location is critical to the operation of CO

detectors. Figure 1 shows appropriate detector locations.

Install detectors according to applicable codes and standards.

Place wall-mounted detectors at least 5 ft. (1.5 m) up from the

floor. For ceiling mounted applications, place detectors at least

1 ft. (0.3 m) from any wall. For combination detectors, follow

the spacing requirements for each sensor. Refer to the control

panel’s application bulletin for the sensor spacing

requirements.

The recommended CO detector locations are:

•Outside each separate sleeping area in the immediate

vicinity of the bedrooms (including areas such as hotel

rooms and dorm rooms)

•On every occupiable level of a dwelling unit, including

basements, but excluding attics and crawl spaces

•Centrally located on every habitable level of the building

and in every HVAC zone based on an engineering

evaluation considering potential sources and migration of

carbon monoxide

•On the ceiling in the same room as permanently installed

fuel-burning appliances

•In any area required by local building codes, legislation, or

the AHJ

•In a suitable environment per the detector specifications

(see “Specifications” on page 4 for details)

•On a firm, permanent surface

Do not install the CO detector:

•Within 5 ft. (1.5 m) of any cooking appliance

•Within 10 ft. (3 m) of a fuel-burning appliance

•Near air conditioners, heating registers, or any other

ventilation source that may interfere with CO gas entering

the detector

•Where furniture or draperies may obstruct the airflow

•In a recessed area

Figure 1: Recommended CO detector locations

Recommended CO detector location

Description

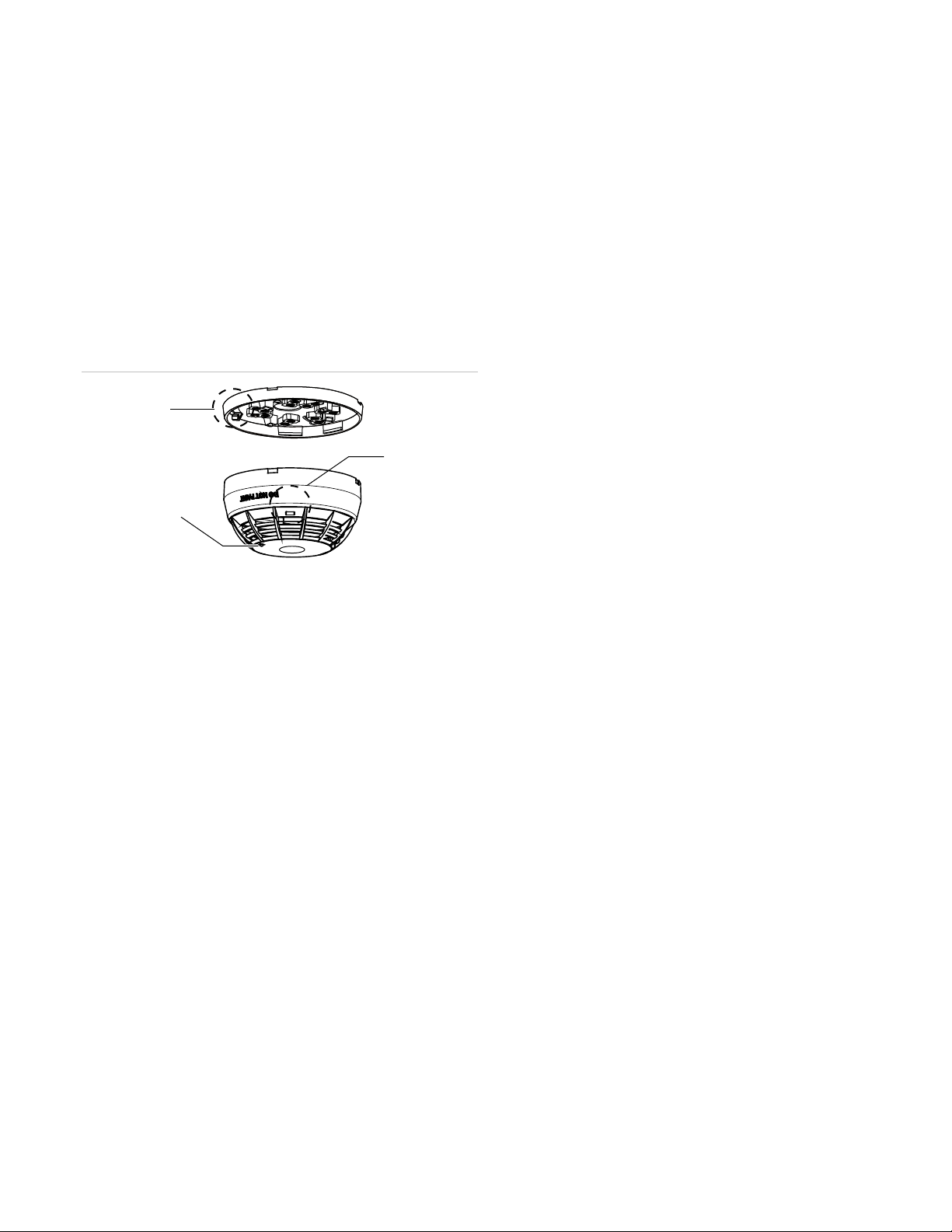

The model V-PCOS Intelligent Photoelectric Smoke Detector

with CO Sensor is an intelligent device that uses an optical

sensing chamber to detect smoke, and a CO sensor to detect

carbon monoxide from any source of combustion. The detector

analyzes the smoke and CO sensors independently to

determine whether to initiate a fire alarm, a life safety CO

alarm, or both.