SECTION TSM 288 ISSUE A PAGE 2 OF 36

DO NOT OPERATE PUMP IF:

- The head is not installed correctly.

- Any guards are missing or incorrectly installed.

- The suction or discharge piping is not connected.

DO NOT place ngers, etc. into the pumping chamber

or its connection ports or into any part of the gearbox if

there is ANY possibility of the pump shafts being rotated.

Severe injury will occur.

DO NOT exceed the pumps rated pressure, speed, and

temperature, or change the system/duty parameters

from those for which the pump was originally supplied,

without conrming its suitability for the new duty. Running

the pump outside of its operating envelope can cause

mechanical contact in the pump head, excessive heat

and can represent a serious risk to health and safety.

Installation and operation of the pump must always

comply with health and safety regulations.

A device must be incorporated into the pump, system,

or drive to prevent the pump exceeding its stated duty

pressure. It must be suitable for both directions of pump

rotation where applicable. Do not allow pump to operate

with a closed/blocked discharge unless a pressure

relief device is incorporated. If an integral relief valve is

incorporated into the pump, do not allow re-circulation

through the relief valve for extended periods, refer to

section 3.8

The mounting of the pump or pump unit should be solid

and stable. Pump orientation must be considered in

relation to drainage requirements. Once mounted, shaft

drive elements must be checked for correct alignment.

Rotate pump shaft by at least one full revolution to ensure

smoothness of operation. Incorrect alignment will produce

excessive loading and will create high temperatures and

increased noise emissions. It may also be necessary to

earth the pump to avoid the build up of a potential charge

difference that could cause a spark.

The installation must allow safe routine maintenance and

inspection (to check for leakage, monitor pressures, etc)

and provide adequate ventilation necessary to prevent

overheating.

SL series pumps are shipped fully lubricated with a lithium

based extreme pressure Grease suitable for sealed for

life units.

Before operating the pump, be sure that it and all parts

of the system to which it is connected are clean and

free from debris and that all valves in the suction and

discharge pipelines are fully opened. Ensure that all piping

connecting to the pump is fully supported and correctly

aligned with its relevant connections. Misalignment

and/or excess loads will cause severe pump damage.

This could result in unexpected mechanical contact in

the pump head and has the potential to be a source of

ignition.

Be sure that pump rotation is correct for the desired

direction of ow (refer to section 3.1).

Do not install the pump into a system where it will run

dry (i.e. without a supply of pumped media) unless it is

equipped with a ushed shaft seal arrangement complete

with a fully operational ushing system. Mechanical seals

require a thin uid lm to lubricate the seal faces. Dry

running can cause excessive heat and seal failure.

Pressure gauges/sensors are recommended, next to

the pump suction and discharge connections to monitor

pressures.

Caution must be taken when lifting the pump. Suitable

lifting devices should be used as appropriate. Lifting eyes

installed on the pump must only be used to lift the pump,

not pump with drive and/or base plate. If pump is base

plate mounted, the base plate must be used for all lifting

purposes. If slings are used for lifting, they must be safely

and securely attached.

DO NOT attempt any maintenance or disassembly of the

pump or pump unit without rst ensuring that:

- The pump is fully isolated from the power source

(electric, hydraulic, pneumatic).

- The pumping chamber, pneumatic relief valve and

any shaft seal support system are depressurized and

purged.

- Any temperature control devices (jackets, heat-tracing,

etc) are fully isolated, that they are depressurized and

purged, and components are allowed to reach a safe

handling temperature.

DO NOT attempt to dismantle a pressure relief valve,

which has not had the spring pressure relieved, is still

connected to a pressurized gas/air supply or is mounted

on a pump that is operating. Serious personal injury or

death and/or pump damage may occur.

DO NOT loosen or undo the head, any connections to the

pump, shaft seal housings, temperature control devices,

or other components, until sure that such action will not

allow the unsafe escape of any pressurized media.

Pumps and/or drives can produce sound power levels

exceeding 85dB (A) under certain operating conditions.

When necessary, personal protection against noise must

be taken

Avoid any contact with hot parts of pumps and/or drives

that may cause injury. Certain operating conditions,

temperature control devices (jackets, heat-tracing, etc.),

bad installation, or poor maintenance can all promote

high temperatures on pumps and/or drives.

When cleaning, either manually or by an in-line cleaning

method, the operator must ensure that a suitable

procedure is used in accordance with the system

requirements. During a in-line cleaning cycle, a pump

differential pressure of between 2 and 3 bar (30 and 45

psi) is recommended to ensure suitable velocities are

reached within the pump head. The exterior of the pump

should be cleaned periodically.

Surface temperature of pump is also dependent on the

temperature of pumped medium.

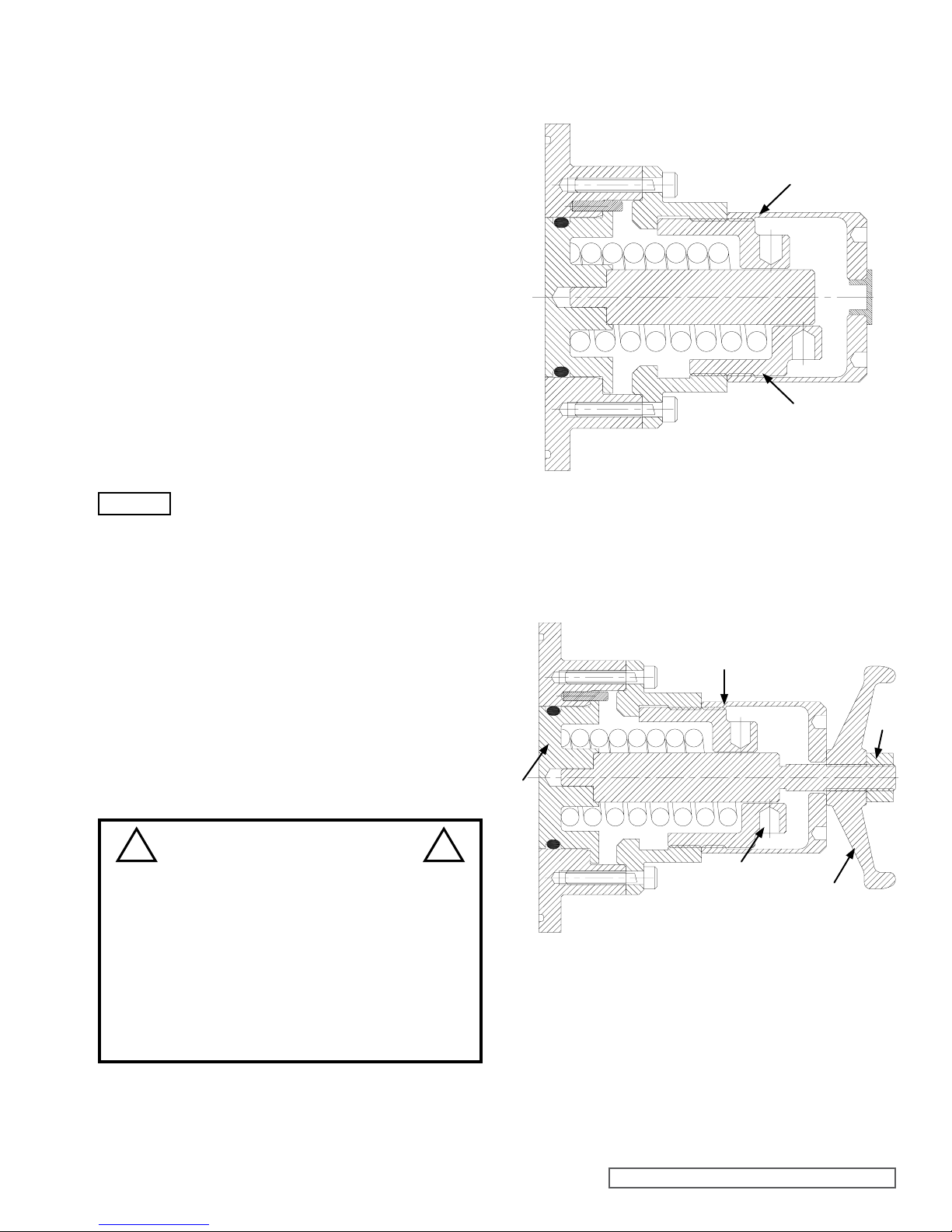

1.0 SAFETY INFORMATION

Danger - Failure to follow the listed

precautionary measures identified by

this symbol may result in serious injury

or death.

Warning - Safety instructions which

shall be considered for reasons of safe

operation of the pump or pump unit and/

or protection of the pump or pump unit

itself are marked by this symbol.

INCORRECT INSTALLATION, OPERATION OR MAINTENANCE OF EQUIPMENT MAY CAUSE SEVERE

PERSONAL INJURY OR DEATH AND/OR EQUIPMENT DAMAGE AND MAY INVALIDATE THE WARRANTY.

This information must be read fully before beginning installation, operation or maintenance and must be

kept with the pump. All installation and maintenance must be undertaken by suitably trained or qualified

persons only.

Symbol

Legend :

!

!

!

!

!

!

!

!

!

!

!

!

!

!

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING