TECHNICAL DATA

May 28, 2013

4” MODEL G-4000P PREACTION

WITH ELECTRIC RELEASE

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com

Preaction 325a

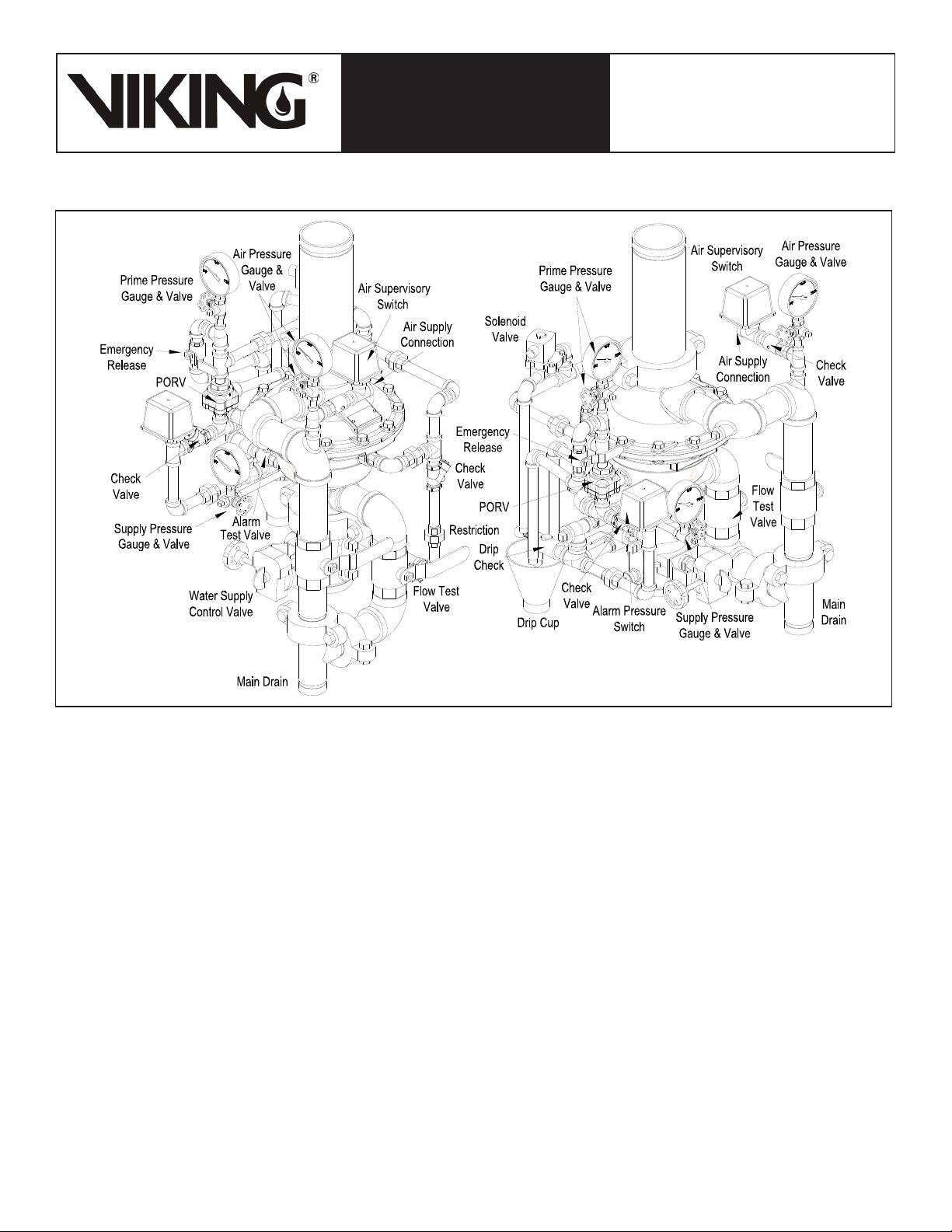

1. DESCRIPTION

The 4” Model G-4000P Electric Release Preaction System Riser Assembly can be used as a

Single Interlock Preaction System with Electric Release, or as a Double Interlock Preaction

System with Electric/Pneu-Lectric Release. These preaction systems are commonly usedThese preaction systems are commonly used

where it is important to control accidental water discharge due to inadvertent damage to the

sprinkler piping. The small profile, lightweight, pilot operated Viking G-4000P Valve comesThe small profile, lightweight, pilot operated Viking G-4000P Valve comes

complete as shown in Figure 8. This pilot operated externally reset valve also includes

an internal check diaphragm, which eliminates the need for a separate check valve

being installed in the system riser.

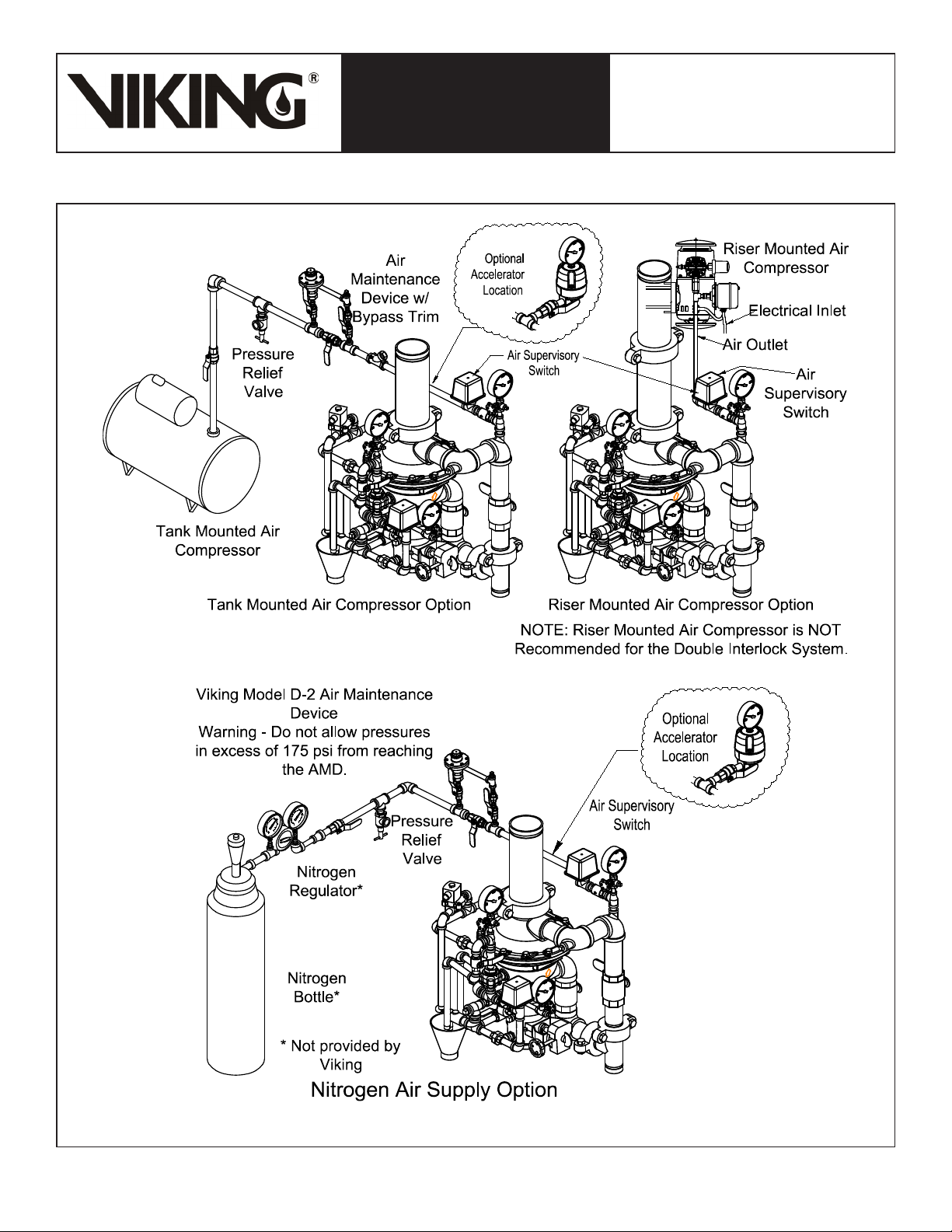

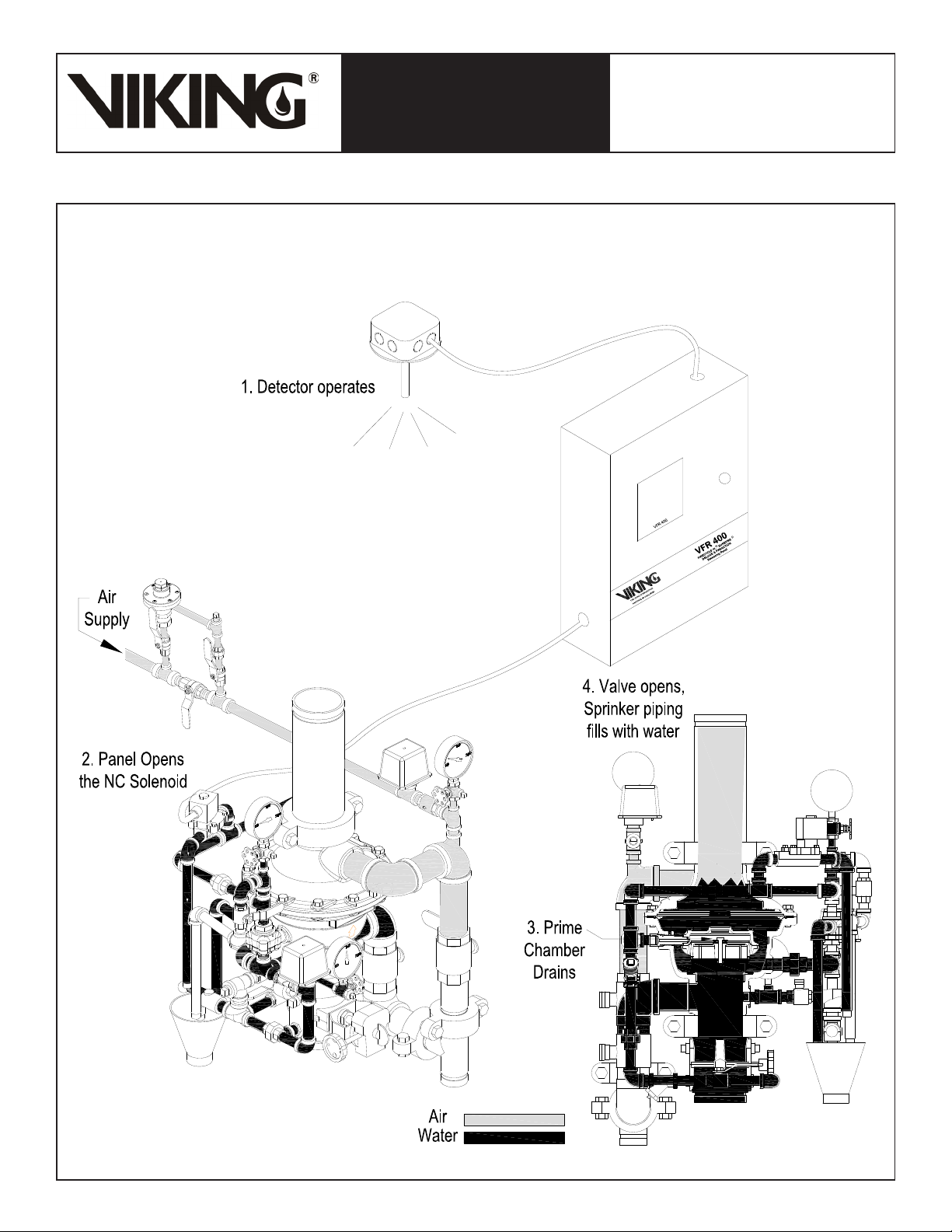

A. Viking Supervised Single-Interlocked Electric Release Preaction Systems

Utilizing the Viking G-4000P Valve

The system piping is pressurized with air or nitrogen as required by NFPA 13 for su-

pervisory purposes only. Viking recommends a minimum of 15 to 20 psi (1.0 to 1.4 bar)

for supervisory air pressure for single interlock systems (refer to Table 2 for double

interlock systems). This feature serves to prevent undetected leaks on the system pip-

ing network. If the system piping or a sprinkler is damaged, the supervisory pressure is

reduced and a “low air” supervisory alarm is activated.

Electrically released preaction systems require a 24 VDC normally closed electric so-

lenoid valve controlled by an approved release control panel with compatible detection

system. In fire conditions, when the detection system operates, the system control

panel energizes the solenoid valve open. When the solenoid opens, the priming water

is relieved from the internal prime chamber assembly. The prime chamber assembly

collapses, and water passes through the G-4000P Valve and internal check diaphragm to the system piping network. The entire

sprinkler system fills with water. The sprinkler piping will remain filled with water until a sprinkler operates.

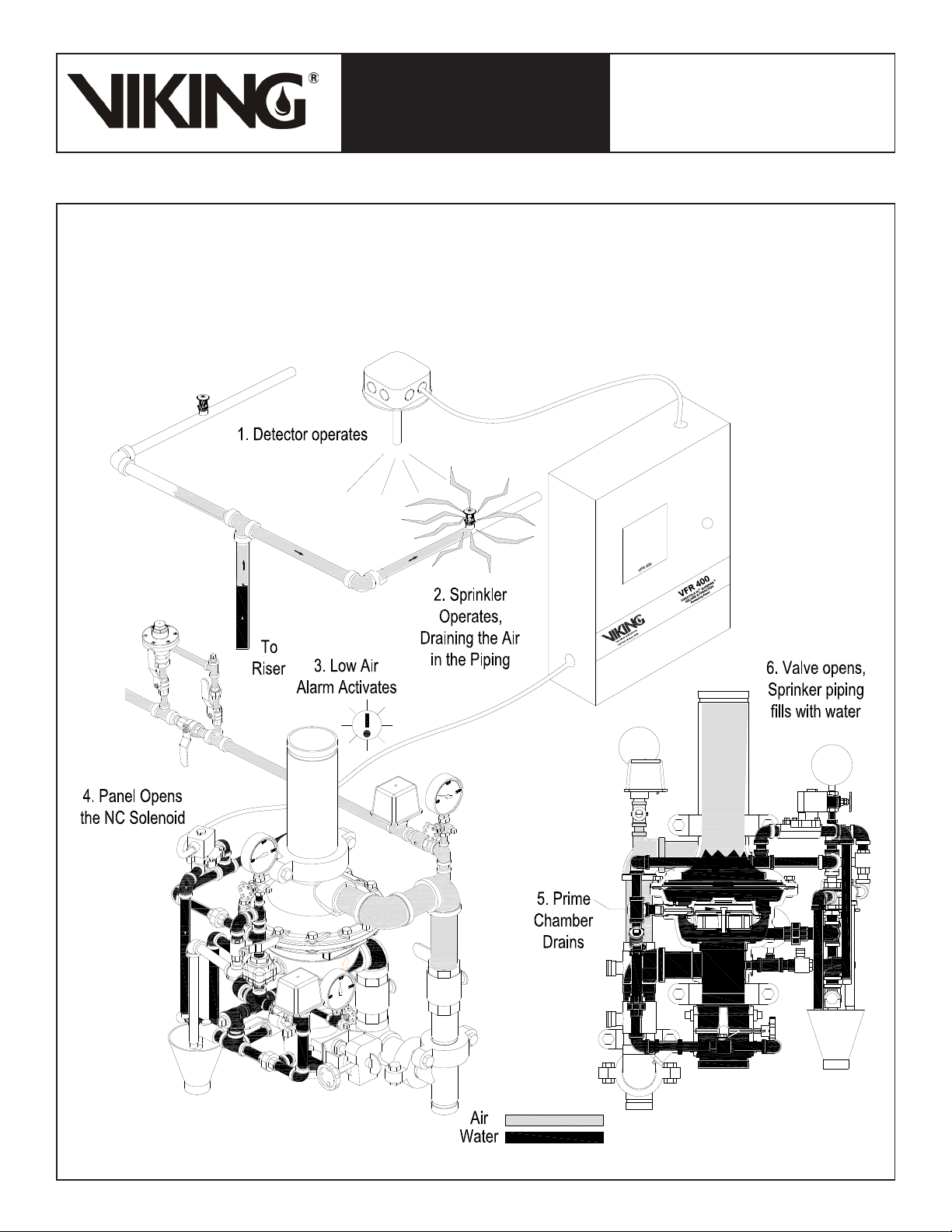

B. Viking Supervised Double-Interlocked Electric/Pneu-Lectric Release Preaction Systems Utilizing the Viking

Model G-4000P Valve.

The system piping is pressurized with air or nitrogen to serve both as a means of supervising the integrity of the piping network

and as one portion of the system release operation. This feature serves to prevent undetected leaks on the system piping net-

work. If the system piping or a sprinkler is damaged, the supervisory pressure is reduced and a “low air” supervisory alarm is

activated.

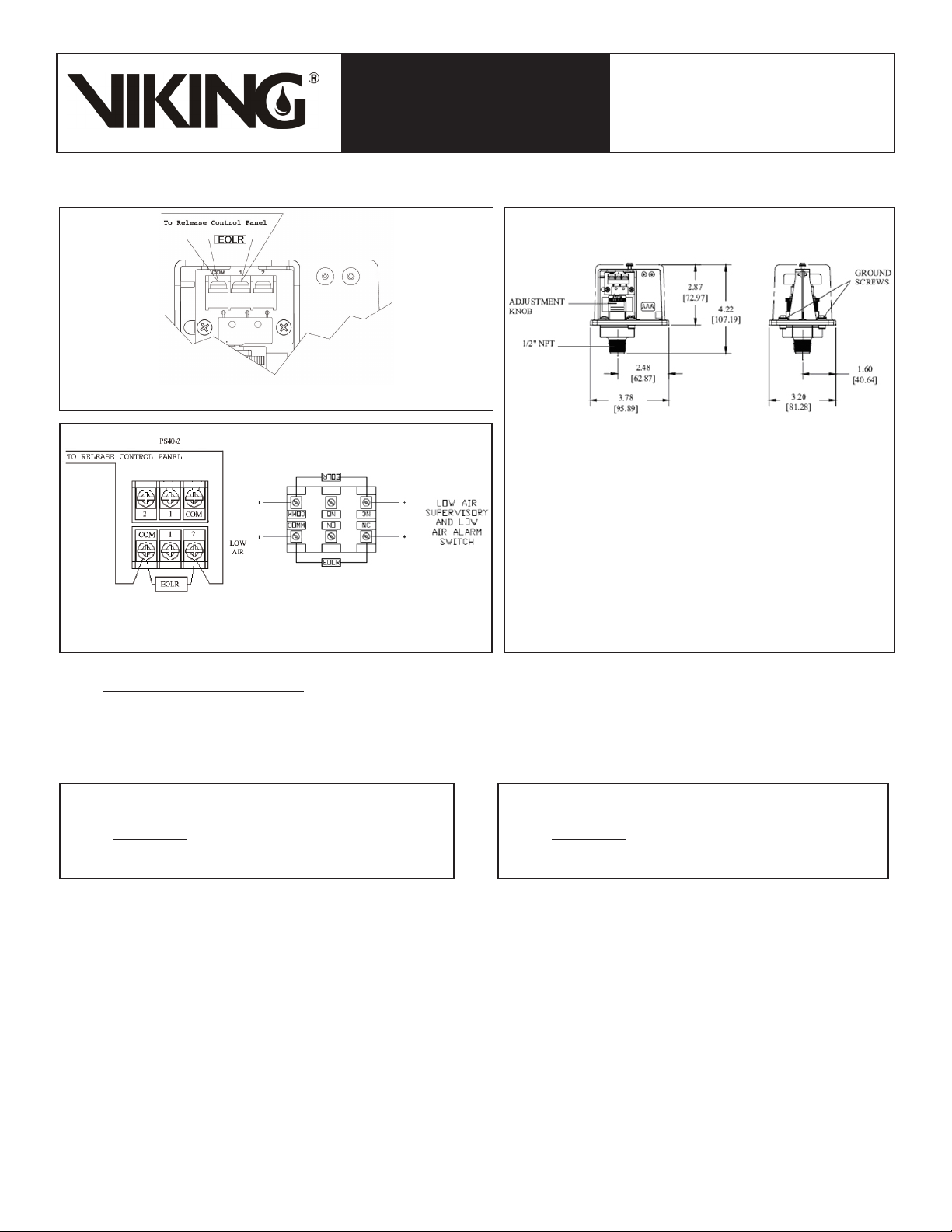

The 24 VDC normally closed electric solenoid and an additional “low air” alarm switch are connected to a compatible release24 VDC normally closed electric solenoid and an additional “low air” alarm switch are connected to a compatible releaseelectric solenoid and an additional “low air” alarm switch are connected to a compatible release

control panel and compatible detection devices. The release control panel is programmed so that a signal from both a release

device and the low air alarm switch must be received before the solenoid is allowed to open. The air pressure switch has two

independently operating connections. The high side is wired as a low air supervisory switch, and the low side is wired as low air

alarm. In fire conditions, a detection device and the low air alarm switch must operate in order to open the solenoid valve. When

the solenoid opens, priming water is relieved from the G-4000P Valve’s internal prime chamber assembly. The prime chamber

assembly is forced open by the system water supply and water passes through the G-4000P valve and internal check diaphragm

to the system piping network. The entire sprinkler system fills with water.

2. LISTING AND APPROVALS

cULus Listed: VLFT

FM Approved: Preaction Sprinkler Systems

3. TECHNICAL DATA

Specifications:

Pressure Rating: 250 PSI (17.2 Bar) Water Working Pressure

Factory Hydrostatically Tested to: 500 psi (34.5 bar)

Friction Loss (Given in feet of Schedule 40 pipe based on Hazen & Williams formula C = 120):

Model G-4000P Valve: 31.2’

12” Section of Pipe: 1’

Water Supply Control Valve: 15’

Model G-4000P Valve CCvFactor: 341

Valve Color: Black

Material Specifications:

Refer to Figure 11.

Viking Technical Data may be found on

The Viking Corporation’s Web site at

http://www.vikinggroupinc.com.

The Web site may include a more recent

edition of this Technical Data Page.

Q = Cv√∆P

S

Form No. F_111608

Q = Flow

Cv =Flow Factor (GPM/1 PSI ∆P)

∆P = Pressure Loss through Valve

S = Specific Gravity of Fluid

Revised page replaces page 325a-m, dated September 2, 2010.

(Revised figure 11 and replacement parts components.)