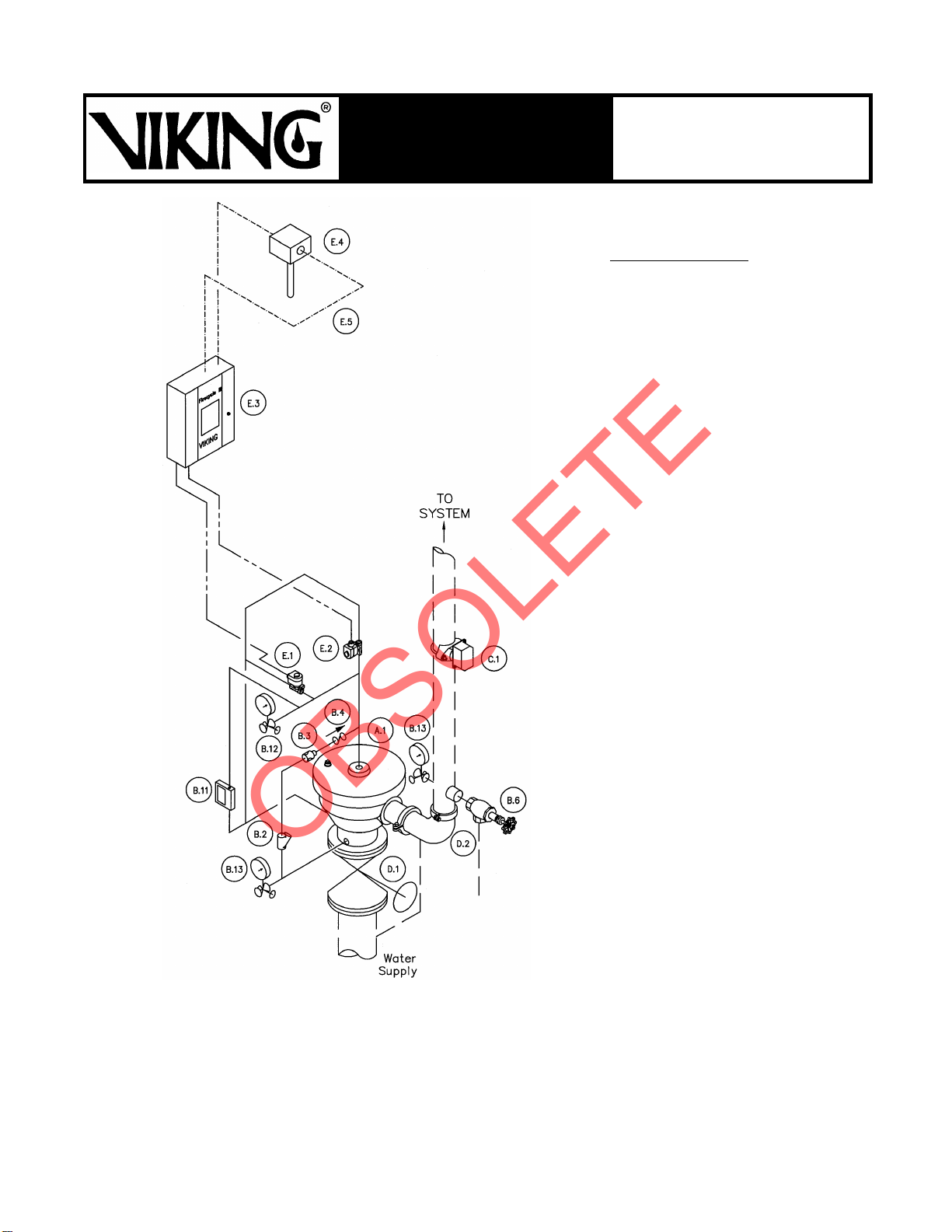

A. SYSTEM DESCRIPTION

(Refer to Figure 1, page 428 c.)

The Viking Firecycle®III Cycling Wet-

pipe System utilizes a Viking Model H-1

Flow Control Valve (A.1) and a Firecy-

cle®IIIControlPanel(E.3),togetherwith

additional valves, devices and trim to

form a unique operating system.

The cycling wet configuration operates

the Firecycle®III System as a normal

wet pipe system with the ability to sense

when the fire has been controlled, and

automatically turn offthe water flow after

a preprogrammed "Soak Timer" has

been satisfied. Should the fire rekindle,

Firecycle®III will initiate the sequence

again. This unique cycling feature will

continue to operate as long as neces-

sary, provided power is available to the

panel, and helps to minimize water us-

age, water damage, and the danger of

pollution to surrounding areas. Batteries

areavailableto provideup toninety(90)

hours of emergency power. If the AC

power fails and the battery backup

power expires while the system is oper-

ating, the deluge system will "fail-safe",

and continue flowing until AC power is

restoredor the system is manually shut-

off.

The Firecycle® III Cycling Wetpipe Sys-

tem has several "fail-safe" features

which are not available on standard wet

pipe systems. Refer to Section B "Sys-

tem Operation" for details.

Wetpipe systems are commonly used

where, when the system operates, it is

desirable to discharge water immedi-

ately from any sprinklers on the system

which may have operated, as in a fire.

Consult all Authorities Having Jurisdic-

tion prior to installing a Firecycle®III

Wetpipe System. The system requires

use of a Viking Flow Control Valve and

trim kit with two Electric Release Sole-

noid Valves (E.1 and E.2) controlled by

the Firecycle®III Control Panel (E.3),

Firecycle®

Detectors(E.4),andDetector

Cable (E.5). The detector temperature

must be lower than the lowest tempera-

ture-rated sprinkler being used. For

properlocation,spacing,andpositioning

of detectors, refer to technical data de-

scribing Viking Firecycle®Detectors.

In fire conditions, when the detection

system (E.4) operates, the Firecycle®III

Control Panel (E.3) energizes normally

closed ReleaseSolenoid Valve #1 (E.1)

open, and energizes normally open Re-

lease Solenoid Valve #2 (E.2) closed,

causing Flow Control Valve (A.1) to

open, allowing water to flow through the

system piping. Water will flow from any

sprinklers attached to the system which

may have operated. When downstream

water pressure exceeds water supply

pressure, the Flow Control Valve (A.1)

performs as a hydraulically operated

check valve to prevent reverse flow.

NOTE: Firecycle®III is a complete sys-

tem, and is listed as a unit. As such, it

is normally not possible to modify the

components of the system controls or

theirinter-relationwithoutcompromising

the listing.

For information on current approvals

and permissible modifications to Firecy-

cle®III, contact The Viking Corporation,

Hastings, Michigan 49058 USA, Atten-

tion: Sales Department.

B. SYSTEM OPERATION

(Refer to Figure 1, page 428 c.)

In the NORMAL condition:

System water supply pressure enters

the primingchamber of theFlowControl

Valve (A.1) through the 1/4" (8 mm)

priming line which includes a Strainer

(B.2), restricted orifice (B.3) and Check

Valve (B.4). Normally open Release So-

lenoid Valve #2 (E.2) allows priming

water to escape so that the Flow Control

Valve (A.1) will not set, but remain open,

filling the system piping with water.

In Fire conditions:

In fire conditions, when the Firecycle®III

detection system (E.4 and E.5) oper-

ates, the Firecycle®III Control Panel

(E.3) activates a piezo sounder and en-

ergizes normally closed Release Sole-

noid Valve #1 (E.1) open and normally

open Release Solenoid Valve #2 (E.2)

closed. Pressure continues to be re-

leased from the priming chamber faster

than it is supplied through the restricted

orifice (B.3). The Flow Control Valve

(A.1) clapper remains fully open to allow

water to flow through the system piping

and to activate alarm devices, including

a Water Flow Alarm Switch (C.1). Water

willimmediatelyflowfromany sprinklers

attached to the system which may have

operated. Water Flow Alarm Switch

(C.1) activates, latching normally open

Release Solenoid Valve #2 (E.2)

closed. Water discharges until all

Firecycle®Detectorshavereset (cooled

below their set point). After all detectors

have reset, the Firecycle®III Control

Panel (E.3) activates the "Soak Timer",

allowing the system to continue dis-

charging water for a preset time period.

When the "Soak Timer" has expired,the

Firecycle®III Control Panel (E.3) de-en-

ergizes normally closed Release Sole-

noid Valve #1 (E.1), allowing it to close.

(The normally open Release Solenoid

Valve #2 (E.2) remains energized

closed until the Firecycle®III Control

Panel is manually reset, or both AC

power and battery backup have failed.)

The Flow Control Valve (A.1) re-primes

and closes, stopping the flow of water

through the system piping.

Should a Firecycle®Detector go into

alarmat this time, the Firecycle®IIICon-

trol Panel (E.3) re-energizes normally

closed ReleaseSolenoid Valve #1 (E.1)

open, and the entire cycle repeats.

To return the system to "Normal" condi-

tions, drain the system piping and re-

place any sprinklers which may have

operated, and any Firecycle®Detectors

which have been damaged. Open the

Emergency Release (B.11) to allow the

system pressure to return to normal.

Once the pressure has stabilized, close

the Emergency Release (B.11) and

press the "System Reset" button on the

Firecycle®III Control Panel (E.3).

Trouble conditions:

If the detection system is damaged or

malfunctions, the Firecycle®III Control

Panel will initiate theappropriatealarms,

and the Flow Control Valve (A.1) will

open. Water will not flow from any sprin-

klers until a sprinkler hasoperated, as in

a fire. The cycling function of theFirecy-

cle®III System will not operate in this

condition, and the system must be

manuallyshutoff. Allalarmswilloperate

normally.

If the piping system is damaged suffi-

ciently to activate the Water Flow Alarm

Switch (C.1), the Firecycle®III Control

Panel (E.3) will energize normally open

Release Solenoid Valve #2 (E.2)

closed. Because a detector has not

gone into alarm mode, Release Sole-

noid Valve #1 (E.1) will remain ener-

gized closed. The Flow Control Valve

(A.1) willre-prime andcloseafterashort

delay. This feature ensures that should

a sprinkler or the system piping become

damaged, the amount of water which

will discharge is limited by the system

pressure and the location of the system

Form No. F_100696

Firecycle®III 428 a

SYSTEM DATA

September 28, 1998

For technical data,

installation, maintenance,

and testing instructions

for individual system

components, refer to current

Viking technical data

describing individual

components of the

system being used.

Viking technical data may be found on

The Viking Corporation’s Web site at

http://www.vikingcorp.com.

The Web site may include a more recent

edition of this technical data page.

FIRECYCLE®III

CYCLING WET PIPE

SYSTEM Pat. Pend.

Replaces page 428a-d, dated August 1, 1997

(updated title block to reflect patent pending).