TECHNICAL DATA

June 1, 2011

6” MODEL G-6000P PREACTION

WITH ELECTRIC RELEASE

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com

Preaction 346a

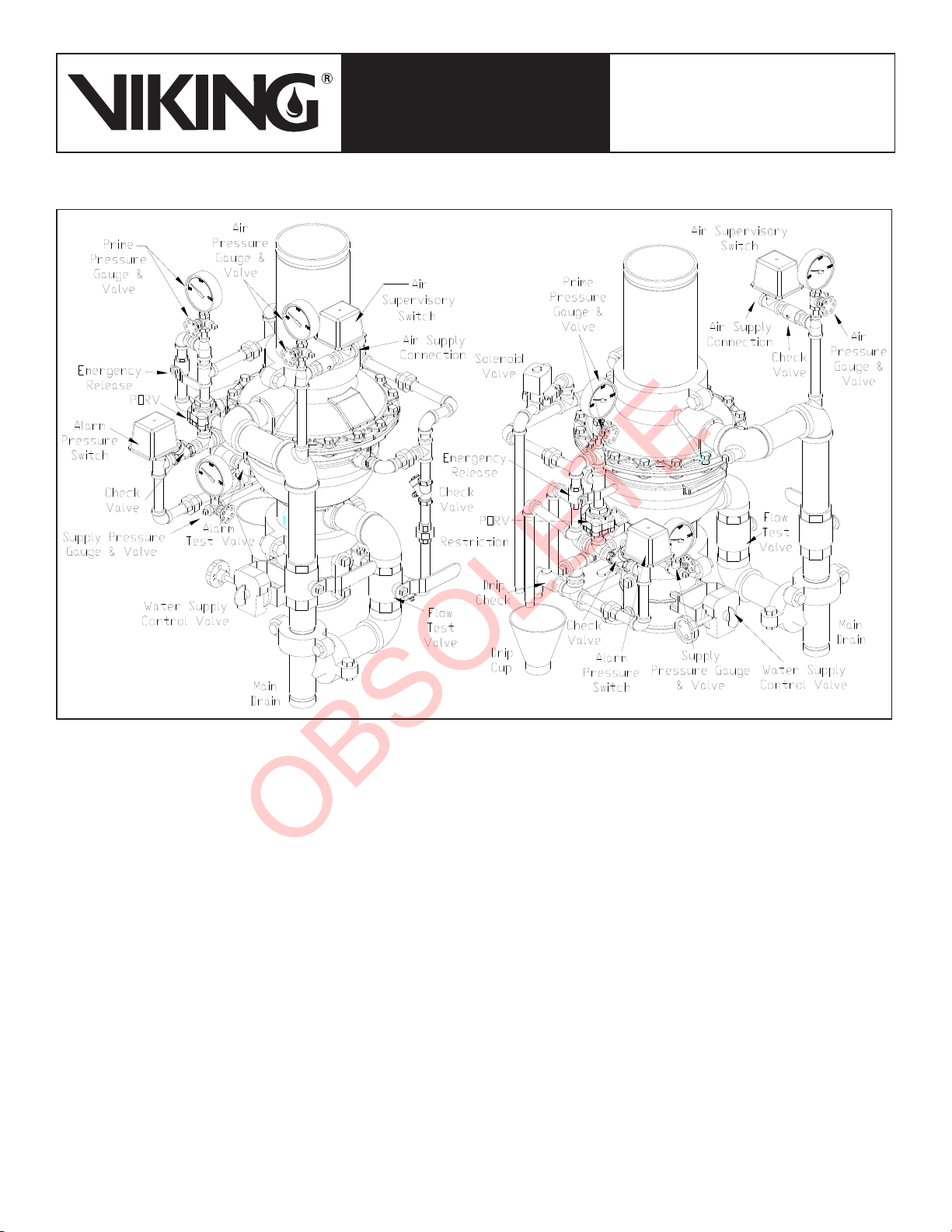

1. DESCRIPTION

The 6” Model G-6000P Electric Release Preaction System Riser Assembly can be used as a

Single Interlock Preaction System with Electric Release, or as a Double Interlock Preaction

System with Electric/Pneu-Lectric Release. These �reaction systems are commonly usedThese �reaction systems are commonly used

where it is im�ortant to control accidental water discharge due to inadvertent damage to the

com�lete as shown in Figure 8. This pilot operated externally reset valve also in-

cludes an internal check diaphragm, which eliminates the need for a separate

check valve being installed in the system riser.

A. Viking Supervised Single-Interlocked Electric Release Preaction Systems

Utilizing the Viking G-6000P Valve

The system �i�ing is �ressurized with air or nitrogen as required by NFPA 13 for su-

interlock systems). This feature serves to �revent undetected leaks on the system �i�-

ing network. If the system �i�ing or a s�rinkler is damaged, the su�ervisory �ressure

is reduced and a “low air” su�ervisory alarm is activated.

-

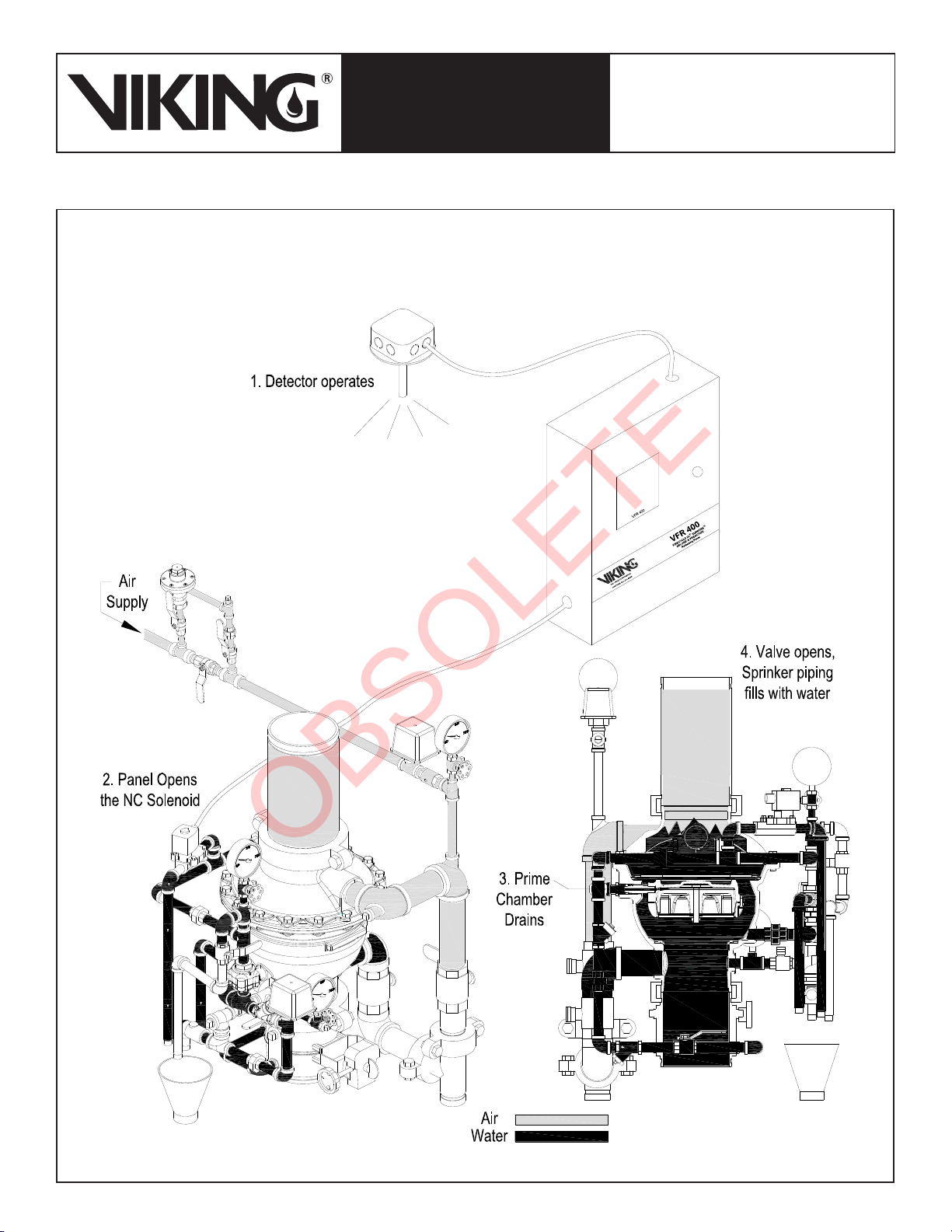

lenoid valve controlled by an a��roved release control �anel with com�atible detection

When the solenoid o�ens, the �riming water is relieved from the internal �rime chamber assembly. The �rime chamber assembly

B. Viking Supervised Double-Interlocked Electric/Pneu-Lectric Release Preaction Systems Utilizing the Viking

G-6000P Valve.

The system �i�ing is �ressurized with air or nitrogen to serve both as a means of su�ervising the integrity of the �i�ing network

and as one �ortion of the system release o�eration. This feature serves to �revent undetected leaks on the system �i�ing net-

work. If the system �i�ing or a s�rinkler is damaged, the su�ervisory �ressure is reduced and a “low air” su�ervisory alarm is

activated.

electric solenoid and an additional “low air” alarm switch are connected to a com�atible release

control �anel and com�atible detection devices. The release control �anel is �rogrammed so that a signal from both a release

device and the low air alarm switch must be received before the solenoid is allowed to o�en. The air �ressure switch has two

inde�endently o�erating connections. The high side is wired as a low air su�ervisory switch, and the low side is wired as low air

and the low air alarm switch must o�erate in order to o�en the solenoid valve. When

assembly is forced o�en by the system water su��ly and water �asses through the G-6000P valve and internal check dia�hragm

2. LISTING AND APPROVALS

cULus Listed:

FM Approved: Preaction S�rinkler Systems

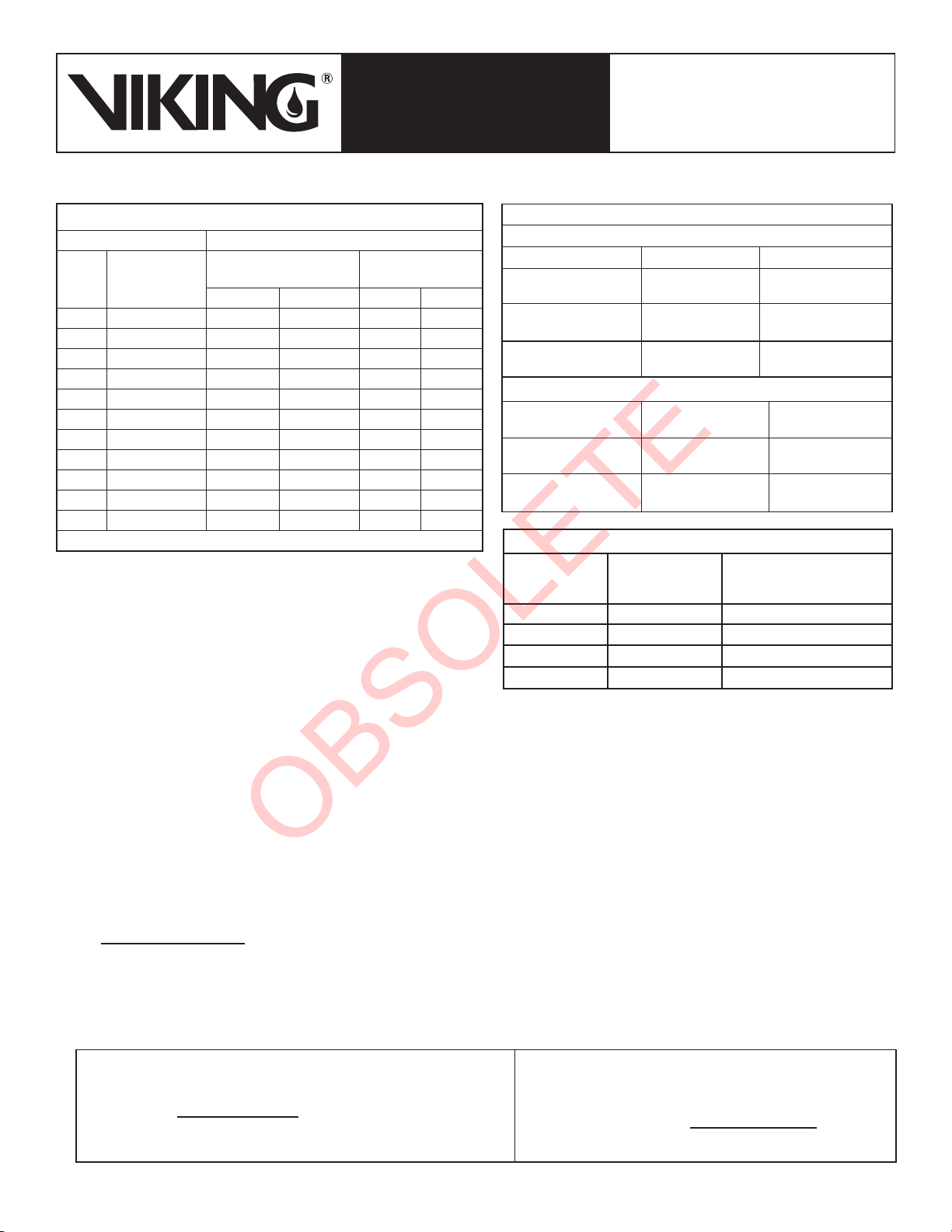

3. TECHNICAL DATA

Specifications:

vFactor: 811

Material Specifications:

Refer to Figure 11.

Flow

P

S

Form No. F_021311

htt�://www.vikinggrou�inc.com.

The Web site may include a more recent

edition of this Technical Data Page.

New �age 346a-m, issued June 1, 2011.