10

TTrroouubblleesshhoooottiinngg

PPrroobblleemmPPoossssiibblleeCCaauusseeWWhhaattTTooDDoo

Refrigerator has an odor Odor producing foods should be covered. Clean according to instructions in use and care

The interior needs cleaning.

Water droplets form Door gaskets are not sealing properly. Clean gaskets according to instructions in use and care.

outside of door Humidity levels are high. Hot, humid weather can increase condensation.

Controls require adjustment. See use and care to adjust controls.

Water droplets form on Humidity levels are high or door has Reduce time door is open. Organize food items efficiently to

inside of refrigerator been opened frequently. assure door is open for as short a time as possible.

Refrigerator or ice maker Normal operation See operating sounds.

makes unfamiliar sounds

or seems too loud

Temperature-controlled Contents of drawer or positioning of items Reposition food and containers to avoid interference with the

drawers do not in compartments is obstructing drawer. drawers.

close freely Drawer is not in proper position See use and care instructions for proper placement.

Drawer channels are dirty Clean drawer channels with warm, soapy water. Rinse

or need treatment. dry thoroughly. Apply thin layer of petroleum jelly to drawer

channels.

Refrigerator runs too Door has been opened frequently or Reduce time door is open. Organize food items efficiently to

frequently has been opened for long periods of time. assure door is open for shortest time.

Humidity levels too high. Normal operation

Food has recently been added. Allow time for added food to reach refrigerator or freezer

temperature.

Refrigerator is exposed to heat by Evaluate refrigerator’s environment. Refrigerator may need to

environment or appliances nearby. may need to be moved to run more efficiently.

Condenser coils are dirty. Clean coils according to instructions in use and care.

Controls need to be adjusted. See use and care manual to adjust controls.

Door is not closing properly. Check for internal obstructions that are keeping door from

closing properly.

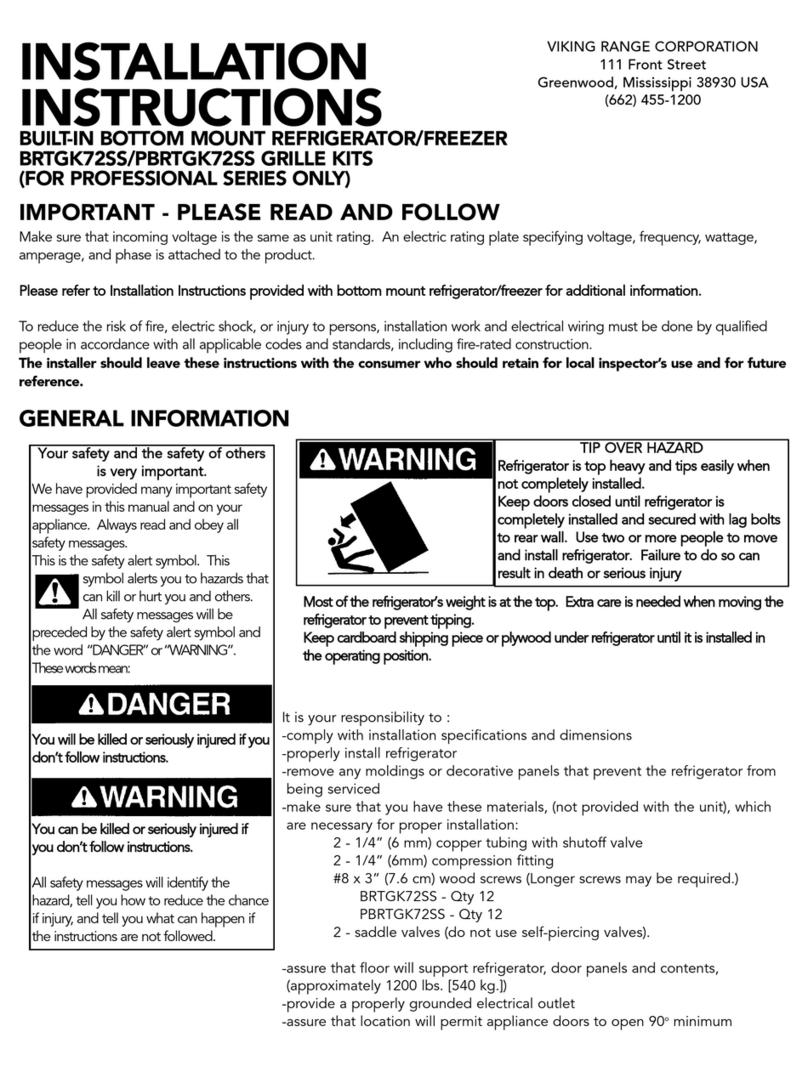

Refrigerator is not level. See installation instructions for details

on how to level your refrigerator. Check gaskets for proper seal,

clean if necessary.

Door gaskets are not sealing properly. See use and care manual for cleaning instructions.

IIcceeaannddWWaatteerr

No indicator lights are lit Freezer door is not closed. Verify that the freezer door is closed. Power is removed from

on dispenser control the control when freezer door is opened.

Refrigerator is not plugged in. Plug in refrigerator.

Fuse is blown or circuit breaker needs to Replace any blown fuses.

be reset. Check circuit breaker and reset, if necessary.

Power outage has occurred . Call local power company to report outage.

Refrigerator is in Sabbath Mode. See Sabbath Mode instructions in use and care manual.

Ice or water are not Freezer door is not closed. Verify that the freezer door is closed. Power is removed from

dispensed when pads are the control when freezer door is opened.

pressed Controls are in lock mode. See Dispenser Lock instructions in use and care manual.

Water tank is filling. At initial use, there is a approximate one to two minute delay in

dispensing while the internal water tank is filling.

Ice bin not installed properly. See Ice and Water instructions in use and care manual.

A large amount of ice has been used. Wait 24 hours for ice production to begin or for ice maker to

restock.

Water pressure is too low. Low water pressure must be between 35 to 100 pounds per

square inch to function properly. A minimum pressure of 35

pounds per square inchis recommended for refrigerators with

water filters.

Water filter needs to be changed. Change water fiter. See use and care manual for instructions.

Ice maker is not producing Ice maker has just been installed or a large Wait 24 hours for ice production to begin or for ice maker to

ice amount of ice has been used. restock.

Water filter needs to be changed. Change water fiter. See use and care manual for instructions.