CONTENTS

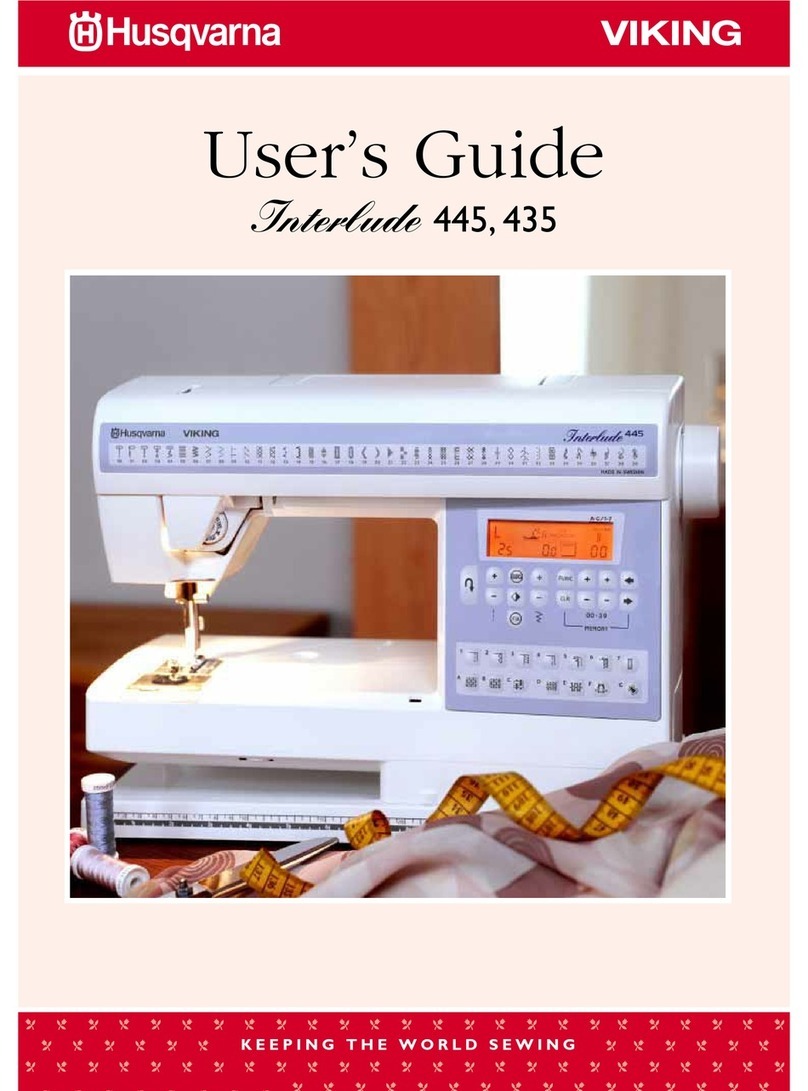

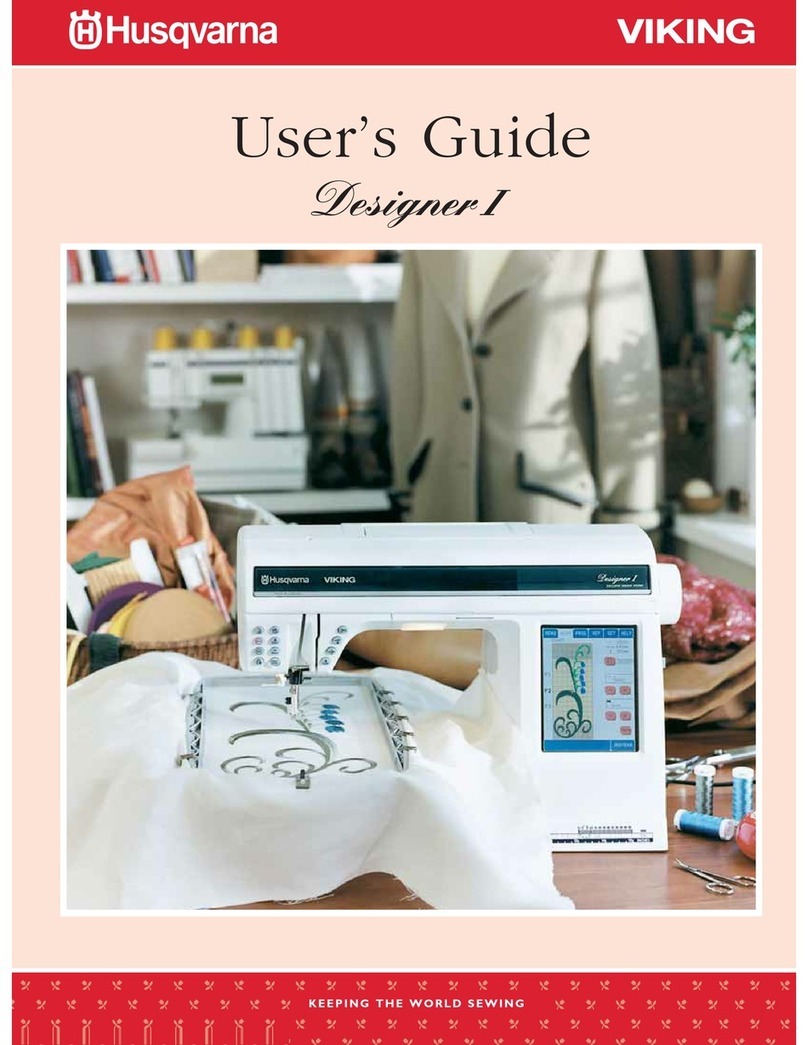

GET TO KNOW YOUR MACHINE

Machine overview.........................................................................................2

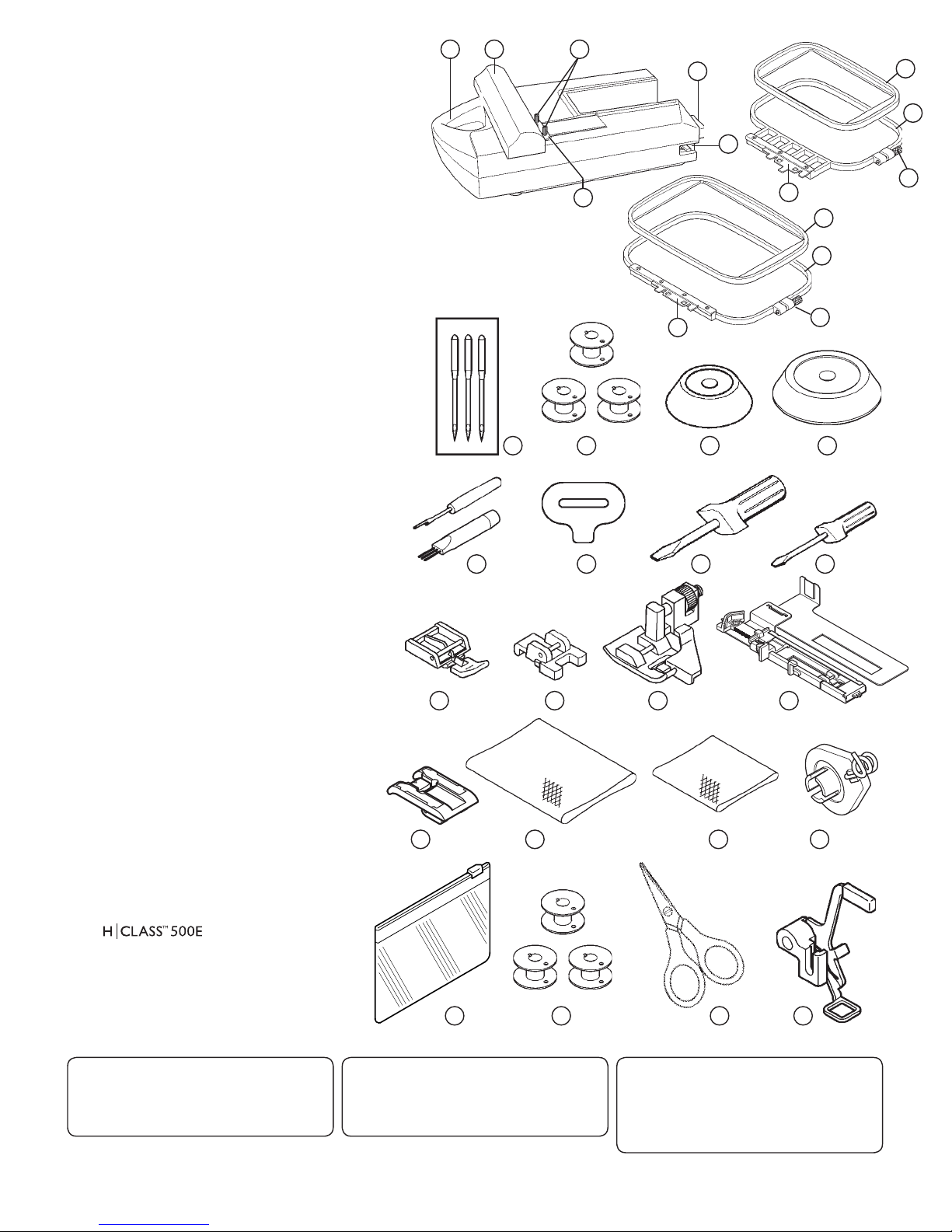

Accessories .......................................................................................................3

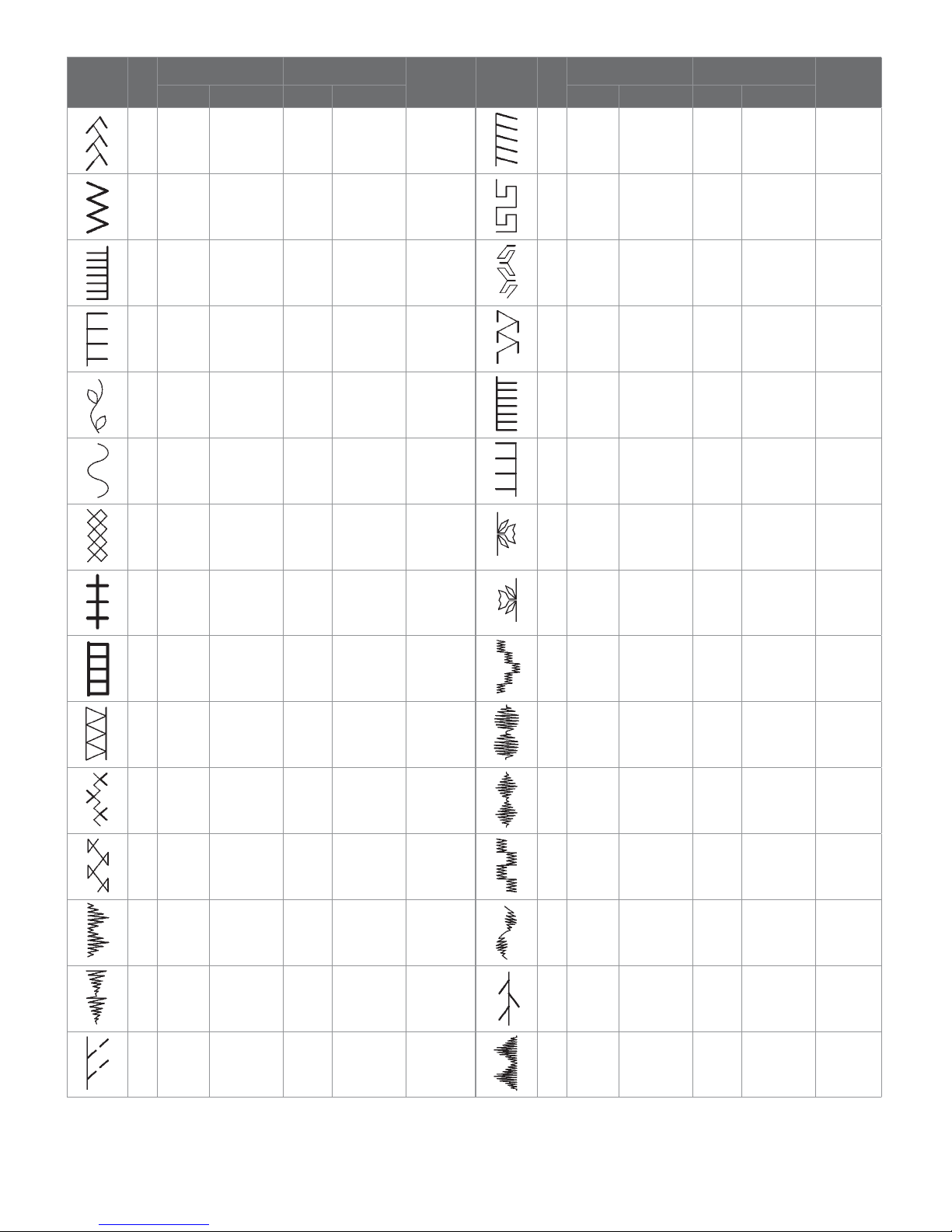

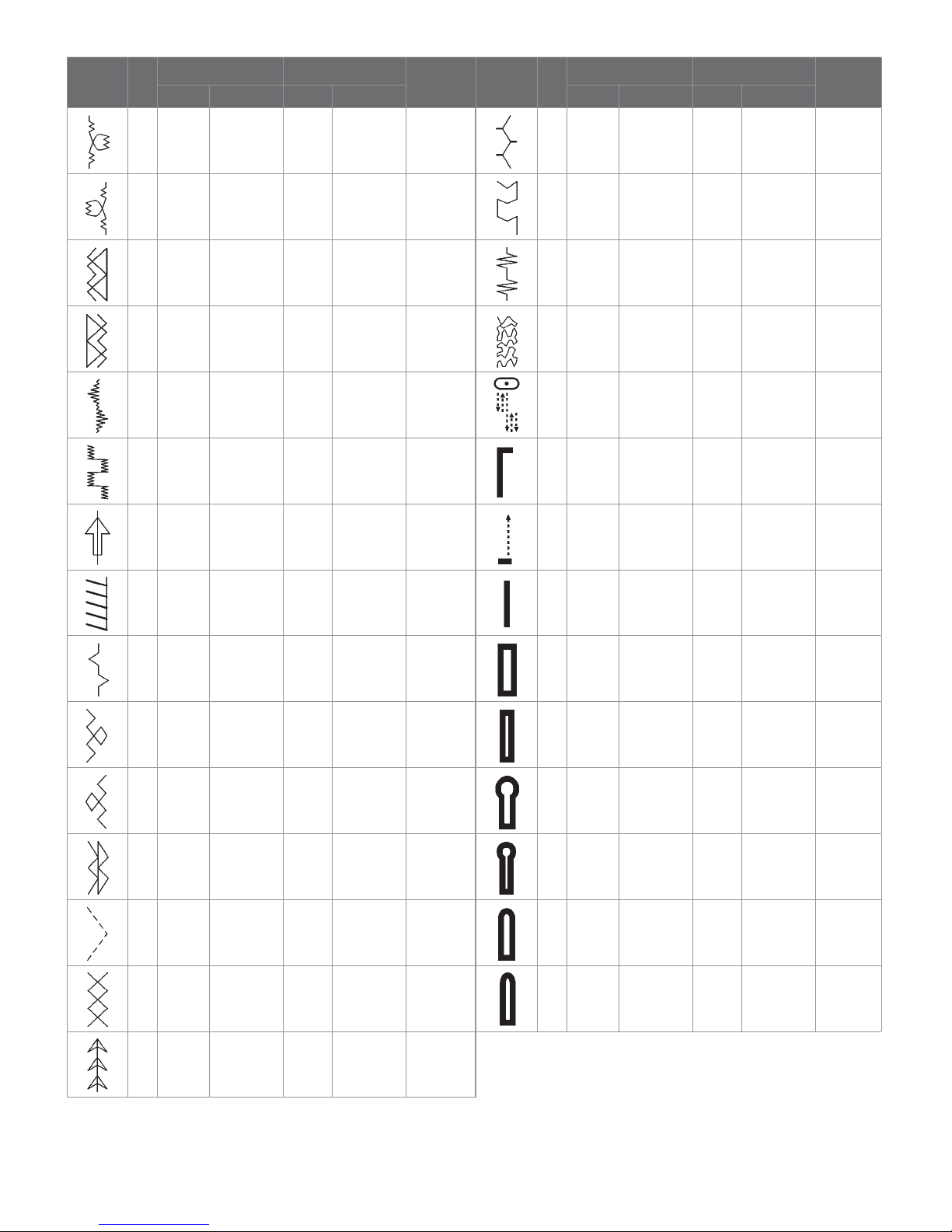

Stitch overview ...............................................................................................4

SET UP YOUR MACHINE

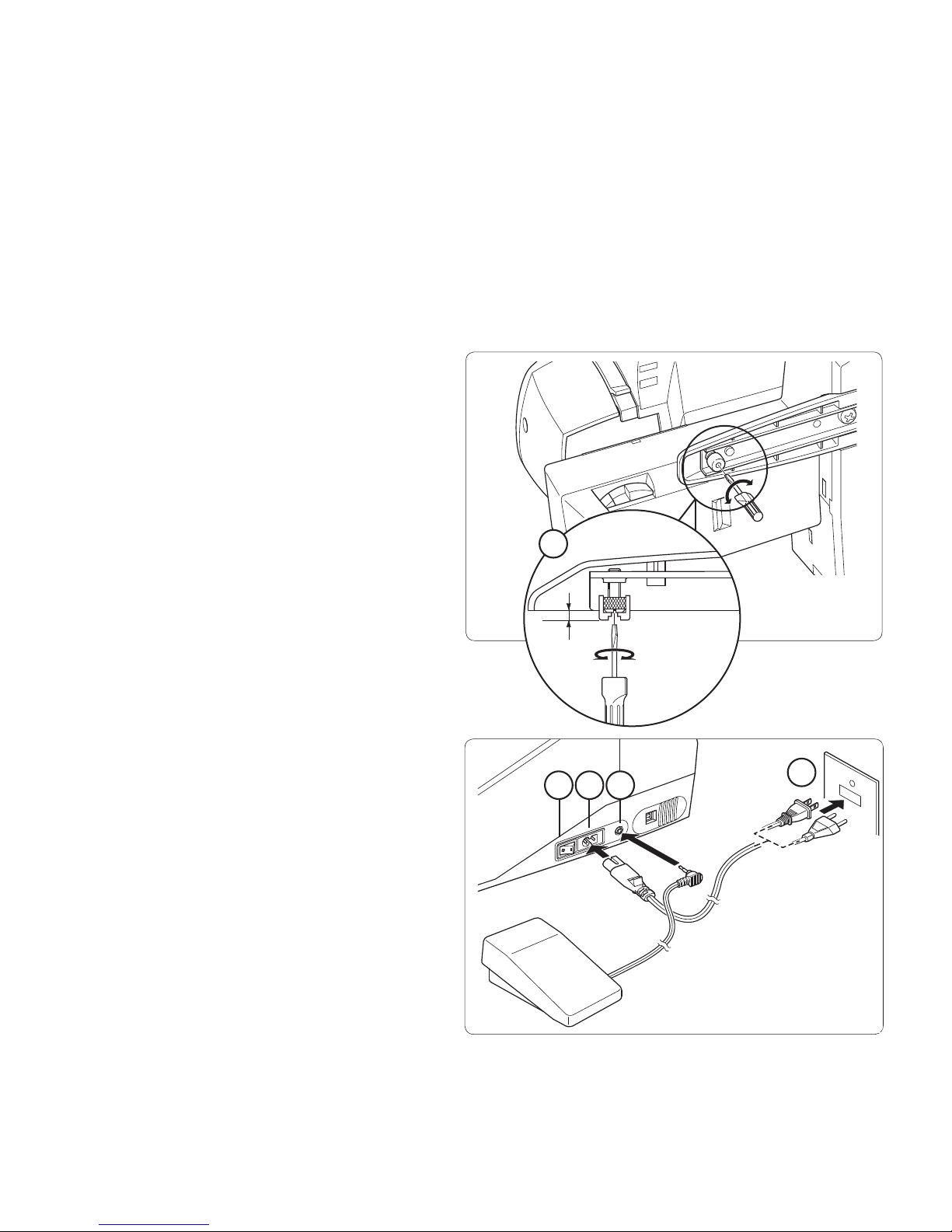

Unpack the machine....................................................................................8

Connect the power cord and foot control....................................8

Pack away after sewing .............................................................................9

Using the free arm........................................................................................9

Lower/raise the feed teeth.......................................................................9

Presser foot lifter ...........................................................................................9

Spool pins........................................................................................................10

Horizontal spool pin.................................................................................10

Vertical spool pin........................................................................................10

Thread the top thread.............................................................................11

Needle threader..........................................................................................12

Threading for twin needle.....................................................................13

Bobbin winding ............................................................................................14

Insert the bobbin........................................................................................15

Pull up the bobbin thread......................................................................16

Adjust top thread tension......................................................................17

Bobbin tension .....................................................................17

Change presser foot.................................................................................17

Changing the needle.................................................................................18

Needles............................................................................................................18

MACHINE FUNCTIONS

Function buttons.........................................................................................19

Needle Stop Up/Down ......................................................19

Reverse...................................................................................19

Start/Stop..............................................................................19

LED indicator.......................................................................19

Control panel functions .........................................................................20

Direct Selection buttons ....................................................20

Numerical Selection buttons .............................................20

Stitch length and width/needle position controls...........21

Twin needle safety................................................................21

Stitch reference guide..............................................................................21

SEWING

Utility Sewing .........................................................................................22-36

Decorative Sewing..............................................................................37-39

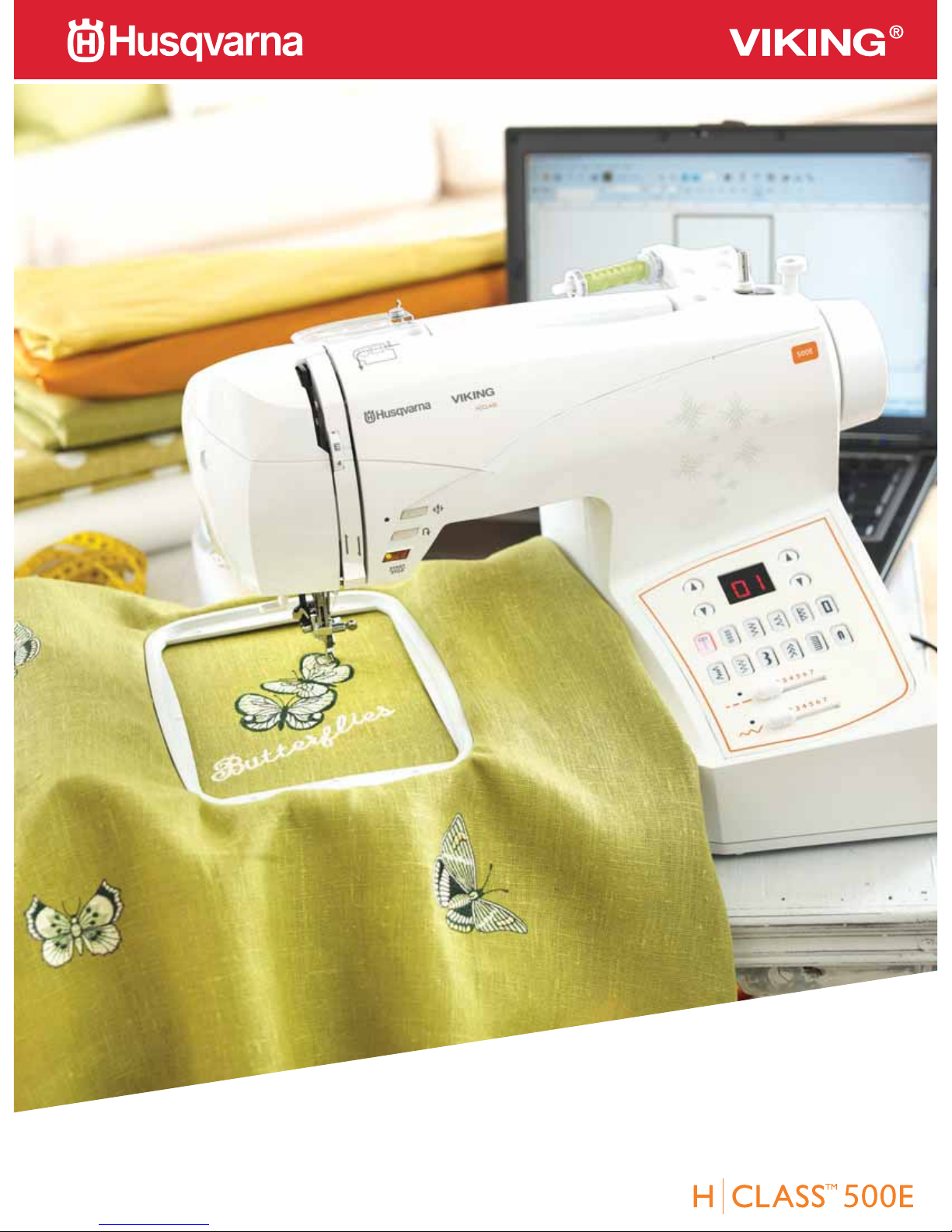

EMBROIDERY

Thread and stabilizer ................................................................................40

Attach the embroidery foot.................................................................41

Thread your machine...............................................................................41

Remove the accessory box..................................................................42

Feed teeth lever..........................................................................................42

Attach the embroidery unit .................................................................42

Remove the embroidery unit..............................................................43

Hoop the fabric...........................................................................................43

Attach and remove the embroidery hoop..................................44

Start embroidering ....................................................................................45

Installation of software.............................................................................45

Function buttons when embroidering............................................47

Start/Stop..............................................................................47

Needle Stop Up/Down .....................................................47

Reverse...................................................................................47

LED indicator.......................................................................47

Thread tension dial .............................................................47

Helpful information when embroidering......................................48

CARE OF YOUR MACHINE

Cleaning and oiling hook area and feed teeth...........................51

Oiling behind the sewing head cover ............................................52

Trouble Shooting ........................................................................................53

Display messages..................................................................53

Sewing....................................................................................55

Embroidery ...........................................................................56