Vinotemp VT-45 User manual

Other Vinotemp Wine Cooler manuals

Vinotemp

Vinotemp VT-12TSMD-2Z User manual

Vinotemp

Vinotemp VT200 User manual

Vinotemp

Vinotemp VT-140TSBW User manual

Vinotemp

Vinotemp WINE-MATE WM-1500HZD User manual

Vinotemp

Vinotemp VT - 28TEDS User manual

Vinotemp

Vinotemp VT-15 TS User manual

Vinotemp

Vinotemp VT-32SN User manual

Vinotemp

Vinotemp WM-3520HZD Instructions for use

Vinotemp

Vinotemp VT-12TEDS-2Z User manual

Vinotemp

Vinotemp WINE-MATE WM-1500HZD User manual

Vinotemp

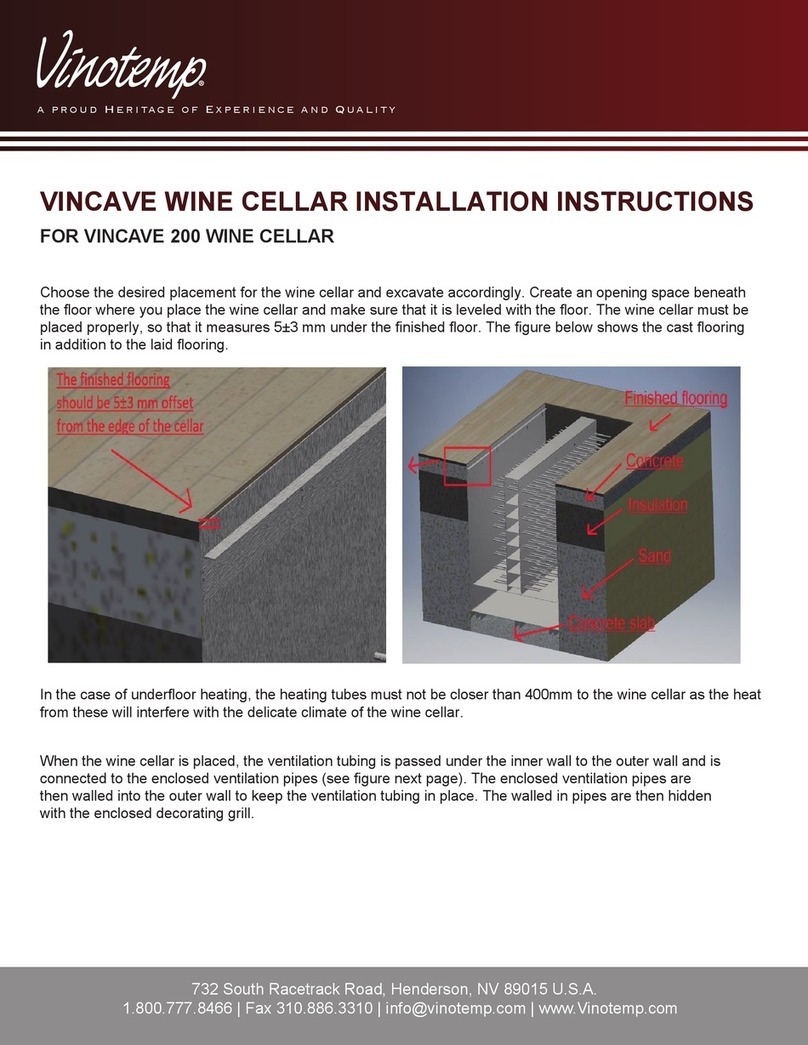

Vinotemp VINCAVE 200 User manual

Vinotemp

Vinotemp VT-6TED-WB User manual

Vinotemp

Vinotemp small VinoCellier User manual

Vinotemp

Vinotemp WINE-MATE VINO3500HZD User manual

Vinotemp

Vinotemp Wine-Mate WM-2500SSDWC User manual

Vinotemp

Vinotemp VT-32TS-FE User manual

Vinotemp

Vinotemp VT-16TEDS User manual

Vinotemp

Vinotemp VT-52SN User manual

Vinotemp

Vinotemp cavanova Romanzo IL-OW006 - 2Z User manual

Vinotemp

Vinotemp VT-24PR125 User manual