2

www.vintageair.com

900194 REV B 09/16/19, PG 2 OF 42

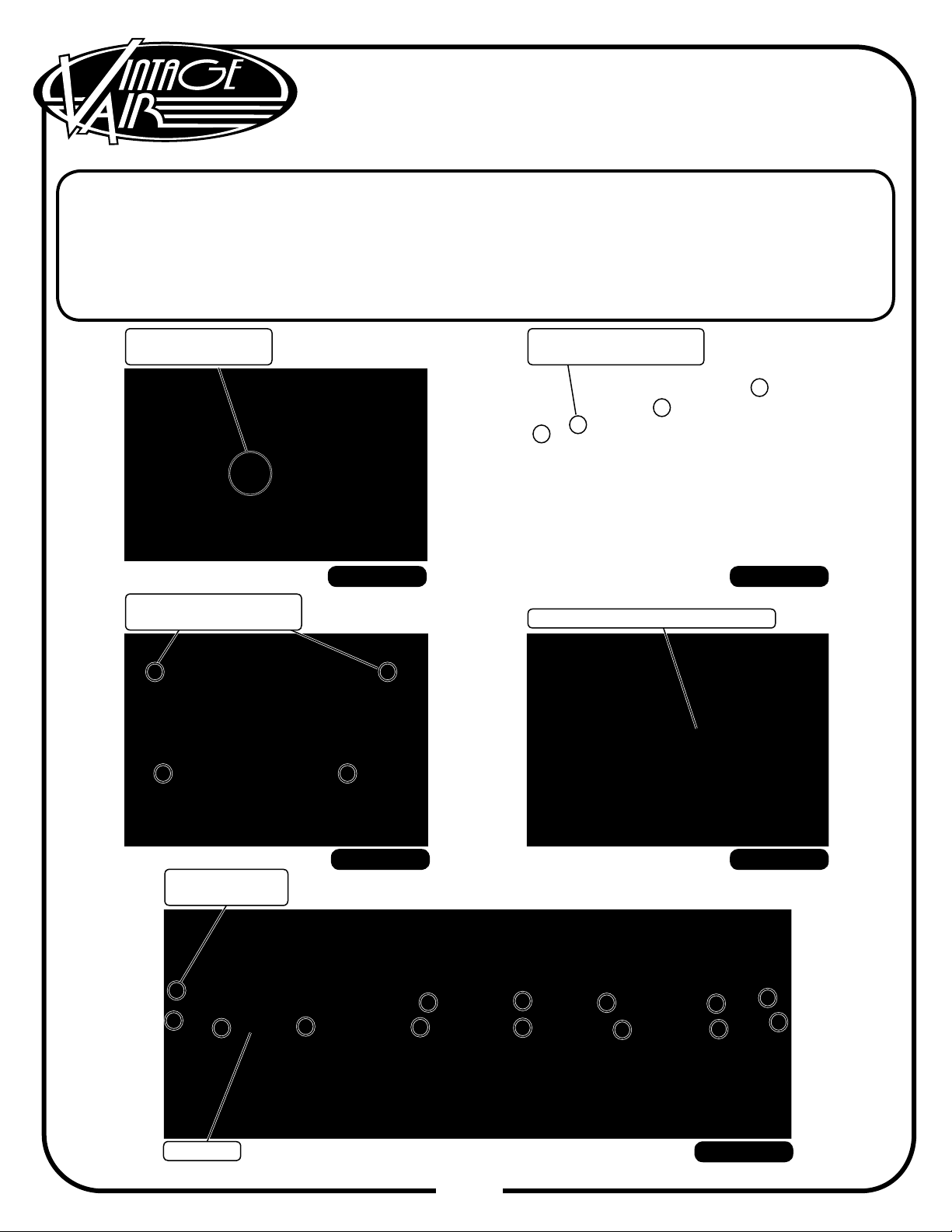

Cover..................................................................................................................................

Table of Contents.................................................................................................................

Packing List/Parts Disclaimer..................................................................................................

Information Page..................................................................................................................

Wiring Notice.......................................................................................................................

Engine Compartment Disassembly..........................................................................................

Passenger Compartment Disassembly ....................................................................................

Condenser Assembly and Installation, Compressor and Brackets, Pulleys, Defrost Duct

Installation........................................................................................................................

Passenger Side Wheel Well and Firewall Modication...............................................................

Engine Compartment, Passenger Side Inner Fender Modication...............................................

Firewall Insulation.............................................................................................................

Lubricating O-rings, A/C Hose Routing & Kick Panel Cap Installation..........................................

Wiring Installation..............................................................................................................

Evaporator Firewall Bracket & Heater Hardline Installation.......................................................

Evaporator Installation........................................................................................................

Evaporator Unit Leveling.....................................................................................................

Radio and Control Panel Installation......................................................................................

Radio and Control Panel Installation with Heater Mounted OEM Controls.....................................

Passenger Side Plenum Assembly Louver Bezel Installation......................................................

Duct Hose Installation.........................................................................................................

Driver Side Underdash Louver Installation.............................................................................

Drain Hose Installation........................................................................................................

ECU Wiring Harness Installation...........................................................................................

Glove Box Installation.........................................................................................................

Heater Control Valve Installation..........................................................................................

A/C Hose Installation..........................................................................................................

Wiring Final Steps..............................................................................................................

Final Steps........................................................................................................................

Wiring Diagram..................................................................................................................

Gen IV Wiring Connection Instruction....................................................................................

Operation of Controls..........................................................................................................

Troubleshooting Guide.........................................................................................................

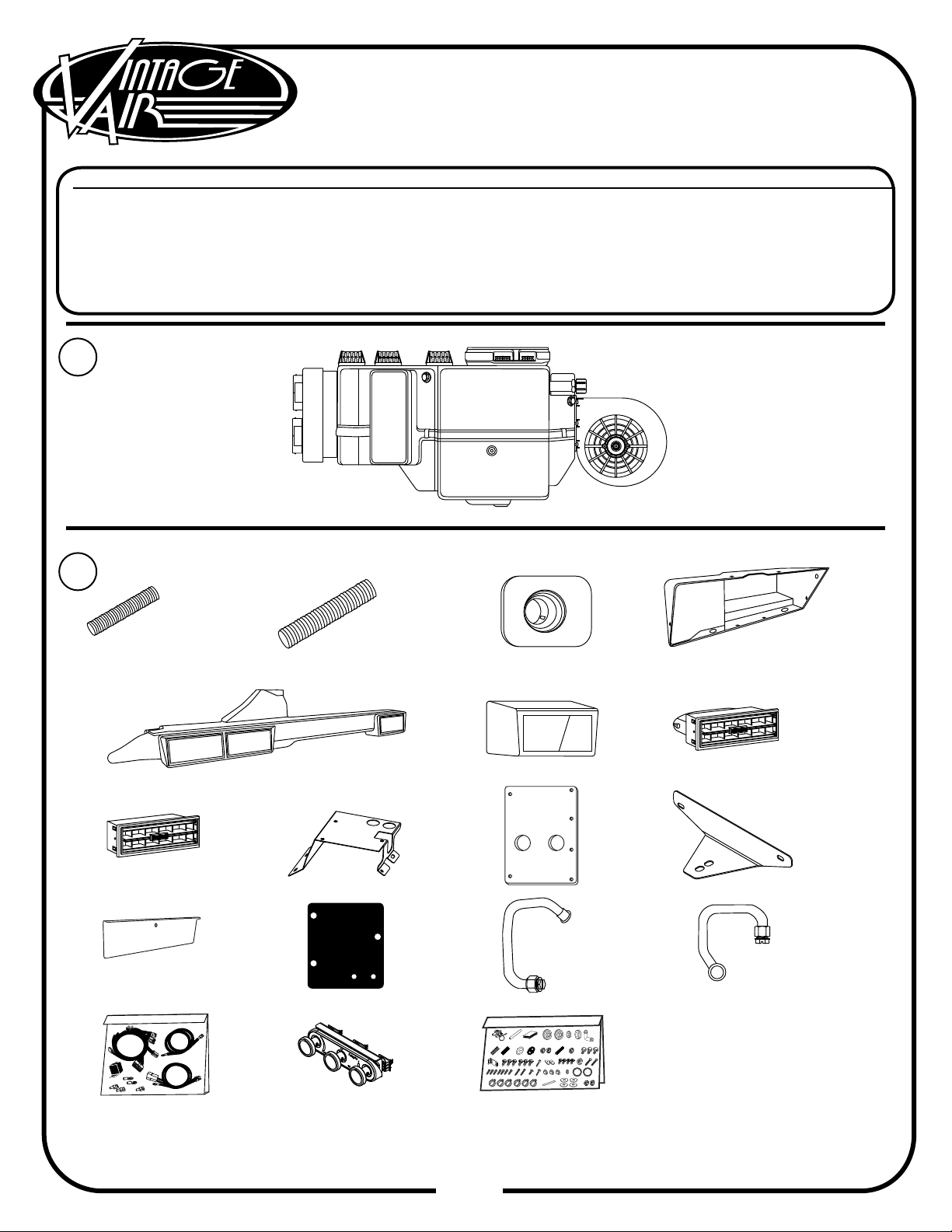

Packing List.......................................................................................................................

1

2

3

4

5

6

7-9

10

11-12

12

13

14-17

17-19

20-21

21-23

24

25

26

27-28

28

29

30

31

32

33

34

35

36

37

38

39

40-41

42

Table of Contents

A detailed tech video outlining the installation process

is available on Vintage Air’s YouTube channel at

http://bit.ly/2kyHG5C.

Viewing the tech video along with the written

instructions will provide the installer the most detailed

installation procedure.