2 3

vinylrecordcleaningsystem.com

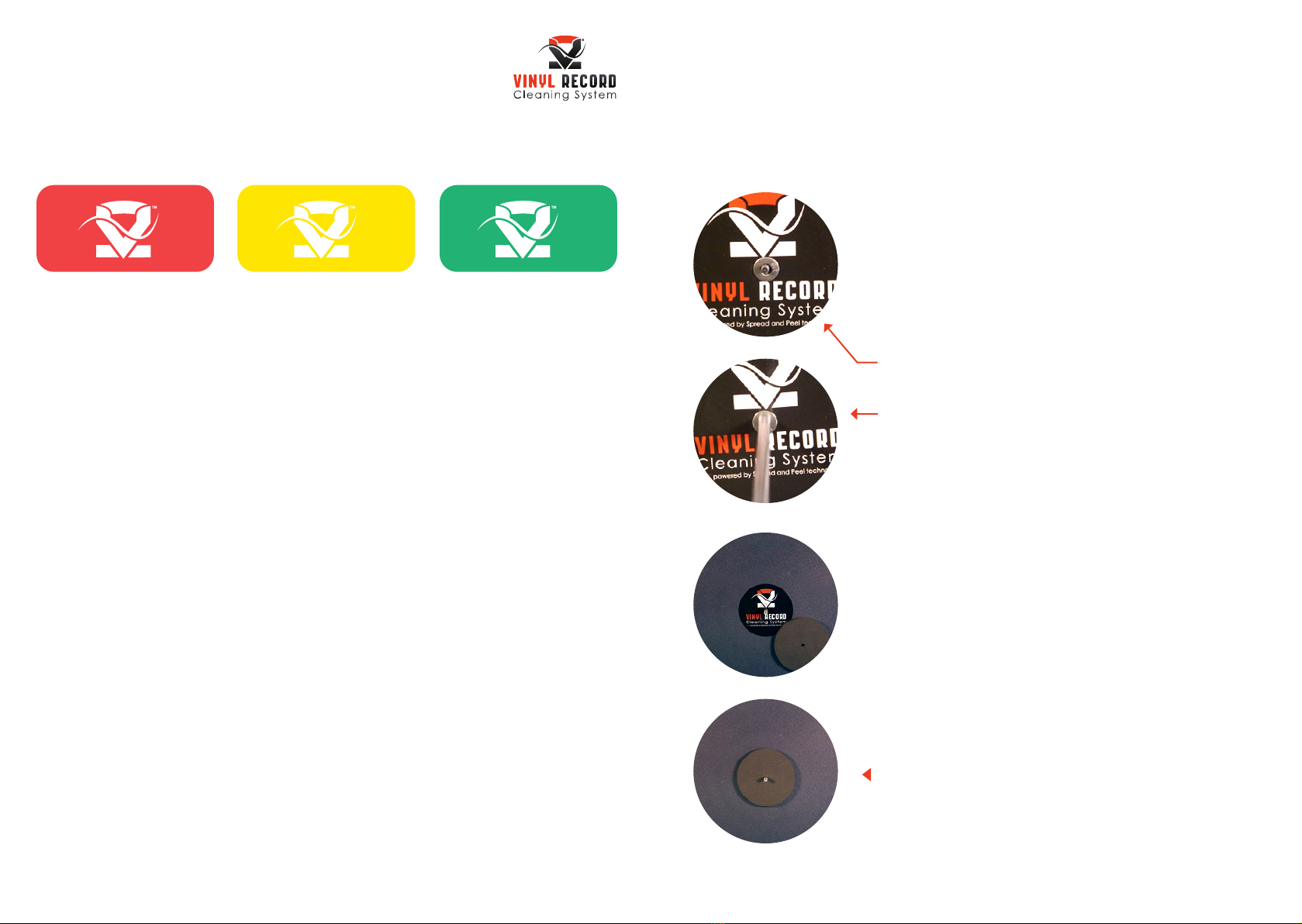

· VRC Platter: features a low friction bearing for

spinning the record during fluid application; table

also doubles as a convenient work platform for

peeling dried film

· Two (2) 90mm VRC Record Support Pucks (RSP)

for use with 12” records and 7” singles: one puck

is used to raise the record o the table surface for

double sided treatment; the second puck is used to

hold the record during cleaning and peeling, also to

protect the label from cleaning fluid

· One (1) 110mm VRC Record Support Pucks (RSP) for

clamping 12” records and protecting the lable

· VRC Easy Spread ‘n’ Peel (ESP)

· Measuring & pouring cup: accurately measure the

recommend quantity of fluid

· VRC Stack Rack base (recycled vinyl)

· 285mm Spindle and mounting screw

· 75mm Stack Rack spacer disks (suitable for all size

records)

· Application brush

· Adhesive tape (for removal of dried film)

· VRC Stylus Tip Cleaner (STC) including STC-Tak

· VRC mini sticker labels (handy for marking the

covers of treated LPs)

IN The BoX BENEFITS

01 02

· Deep cleaning of

record grooves

· An 11db increase in overall

signal to noise ratio and an

8db improvement to the

peak noise floor (over 50%)

· Fast drying

· Easy application and

removal

· Ecient: Ten x 12” LPs

per 100ml

· Film is peeled by first lifting

with adhesive tape

· Elimination of static

electricity

· Original playback for

decades to come*

*with regular maintenance

VRC Easy Spread n’ Peel (ESP) is unique.

It achieves total removal of all unwanted

contaminants in the record groove by

suspending this material in solution which

then dries to a pliable film. Peeling o

the dried film removes all the suspended

matter from the record groove. At the

same time ESP eliminates static electricity

and stops it reoccurring.

All liquid record cleaning methods create

slurry. Failure to fully remove the slurry

means a coating is left on the groove

walls. Comprised of the tiniest particulate

matter this will manifest itself as dullness

in playback sound rather than the clicks

and pops usually associated with a dirty

record groove. It will also be abrasive to

the stylus.

No static electricity. The original cause

of noise is static electricity, either through

its discharge into the cartridge or its

anchoring of airborne dust to the record.

A vinyl record is easily charged unless it

is protected. ESP leaves behind an inert,

anionic film about a molecule thick, an

eective shield against static.

ESP Features

Important:

Do not dilute VRCESP