APPLICATIONS

The VIPCOLOR VP485 Rewinder is used to rewind labels onto a 76mm (3”) core holder. The

rewinder can handle labels up to 220mm (8.6”) wide and rewind rolls with external diameter up

to 250mm (10”).

POWER SUPPLY

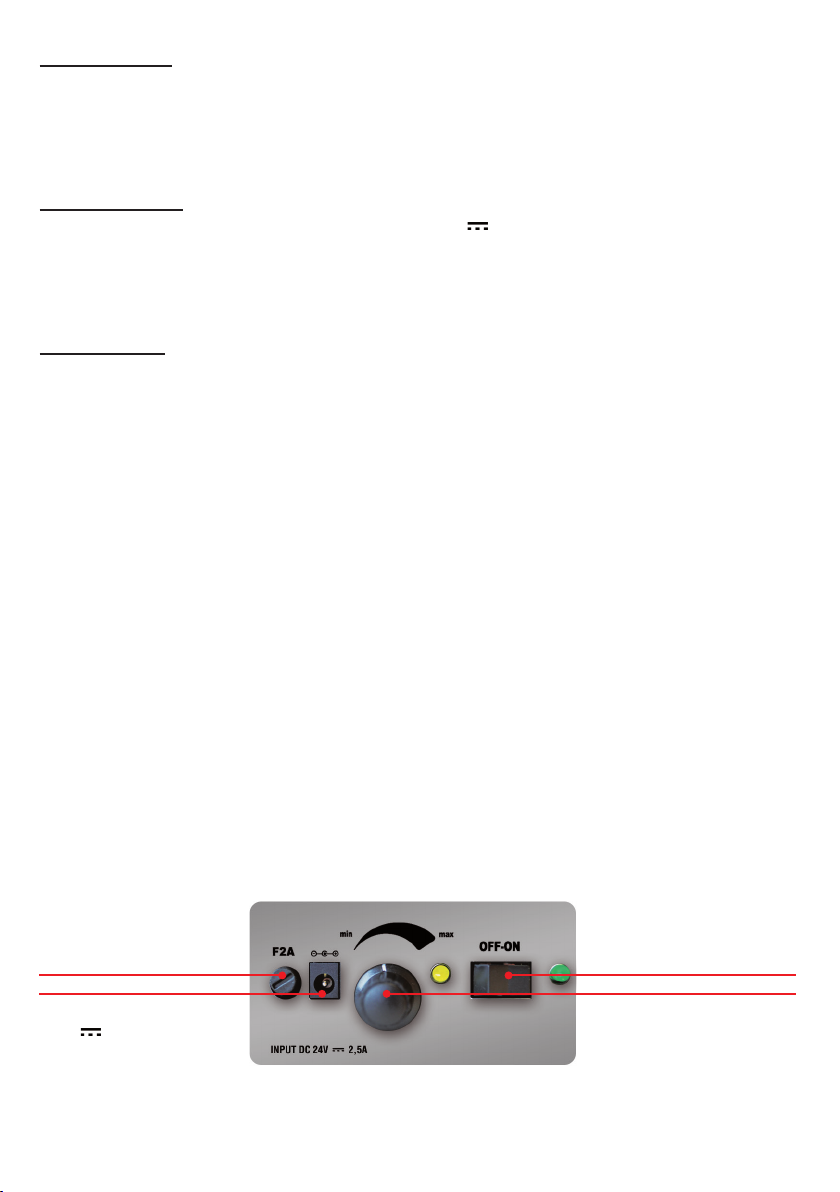

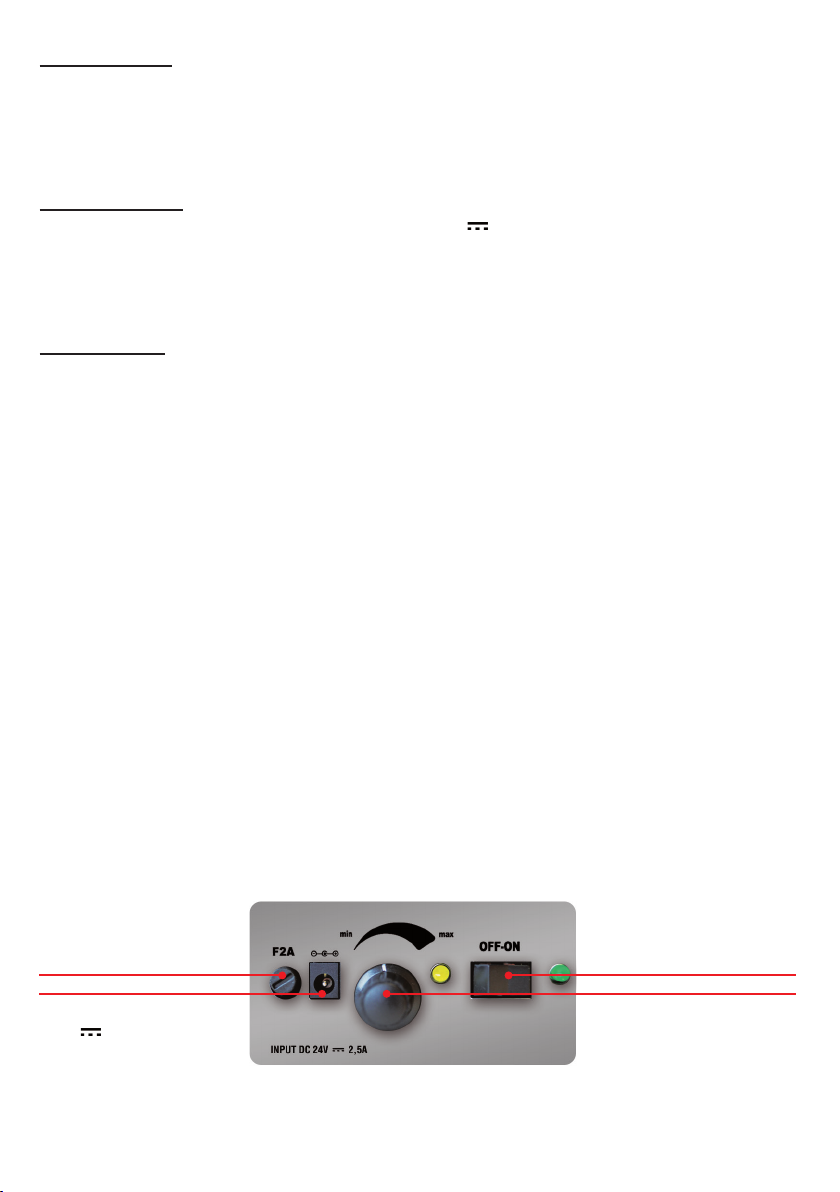

An external power supply 100/240VAC - 2.5A at 24V allows an electronic circuit to provide,

through the tension arm, the adjustment of the rotation’s speed and rotation’s direction. A 2A fuse

is used as protection.

FUNCTIONING

The feet of the printer must be placed into the slits of the base named “R” (for the model

RV1234-S4 only). In this way the correct rewinding operations are guaranteed and the rewinder

is safely fastened to the printer.

The VIPCOLOR VP485 rewinder has two types of speed adjustment: it is possible to set the

main speed through a knob and the tension arm automatically adjusts the speed from zero up

to the selected speed.

The position of the tension arm is calibrated as follows:

- When the printer forwards the media for printing, the tension arm goes down and the device

rewinds the media.

- When the tension arm is in the middle position, the device is idle.

- When the printer pulls back the media, the tension arm goes up and the device unwinds it.

When the rewinding operations are nished, the rewinder stops, thanks to the contact between

the tension arm and the base and an acoustic signal sounds to let you know that the rolls of

labels are ready.

2A Fuse

Input DC:

24V 2.5A

ON-OFF

Speed control