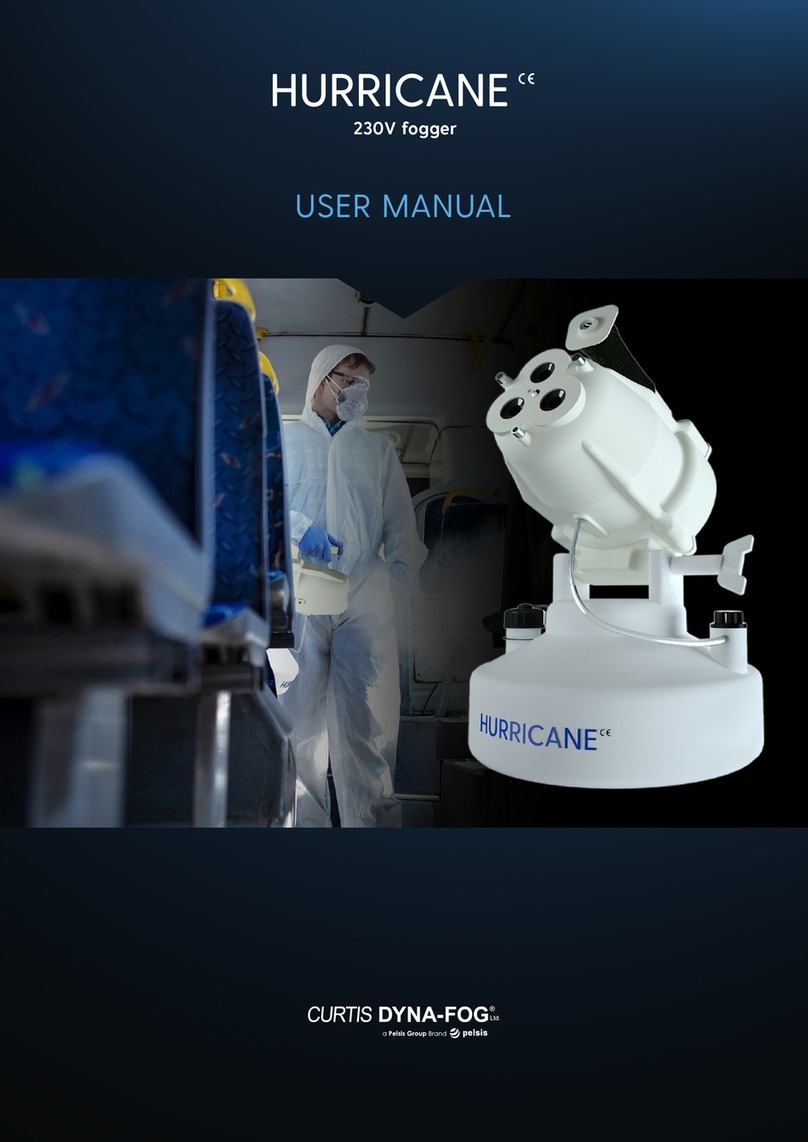

VIROSMART VS-500 ULV User manual

VS-500 ULV Device

User Manual

VS-500 ULV FOGGER USER MANUAL

PLEASE READ BEFORE USE

VIROSMART is a trading name of DARS Management Co Ltd

Company Registrtion Number: 11947523

Tel: +44 1452 865255 Email: [email protected]

www.virosmart.co.uk

VS-500 ULV Device

User Manual

Safety Precautions

•You must ensure the machine is connected to the correct power

supply. Connecting the machine to the wrong voltage could cause

the motor to overheat and cause a fire.

•Always use a 13A RCD Adaptor plug between the fogging machine

and your 230v power supply.

•Only connect to 220 - 230v power supply.

•Do not connect to a 110v power supply.

•Never move the machine by pulling on the power cord.

•In case of any exposed wiring, damage to the machine or any of its

components, turn off immediately at the wall socket and do not use.

Take to an authorised centre for repair.

•Do not modify the machine –this will void the warranty and

compromise the safety of the machine.

•Do not Inhale the fog/mist when spraying. The mircro-

droplets are quickly absorbed into the lungs. Depending on the

chemical being used this could result in serious injury or death.

•Do not fog a flammable liquid. The motor produces heat and could

be a source of ignition.

•You must wear protective equipment (face/breathing mask, gloves

and protective clothing). Ensure you have studied the safety data

sheet of the chemical you are using and protect yourself accordingly.

•Keep the machine away from children.

VS-500 ULV Device

User Manual

Warning! Please read all the necessary instructions before using the Device. The most important,

follow all the safety measures indicated in this user manual. Obey the maintenance rules. Following

the maintenance rules would extend the device’s life. Please contract with HSC makina technical

service about your questions.

Package and Environmental Health

Please keep your device in its original package for no damage to occur during shipment and

transport. If you no longer need the package, dispose or store it in accordance with the instructions

related to environmental health. Package material is recyclable. Dispose of the device at the end of its

lifetime in accordance with the related instructions.

VS-500 Overview

Use the VS-500 for disinfection, pest control, odour control and plant protection.

The VS-500 works by expelling a fine, almost invisible mist into the atmosphere which eventually

settles on all surfaces including those impossible to reach by conventional methods.

The machine is compact, lightweight and robust. The large 5 litre tank and powerful 1400w 240v

electric motor allow the covering of large areas with ease.

The ability to adjust the fogger output from a vapour of just 9 μm up to a fog 49 μm, and flow rate up

to 49 litres per hour makes this machine suitable for the application of disinfectants, biocides,

fungicides and pesticides.

Regular fogging with an approved disinfectant such a Virosol as will help prevent the cross-infection

of viruses such as MRSA, Covid 19 Coronavirus (human and feline), Strangles, Ringworm and many

more

VS-500 ULV Device

User Manual

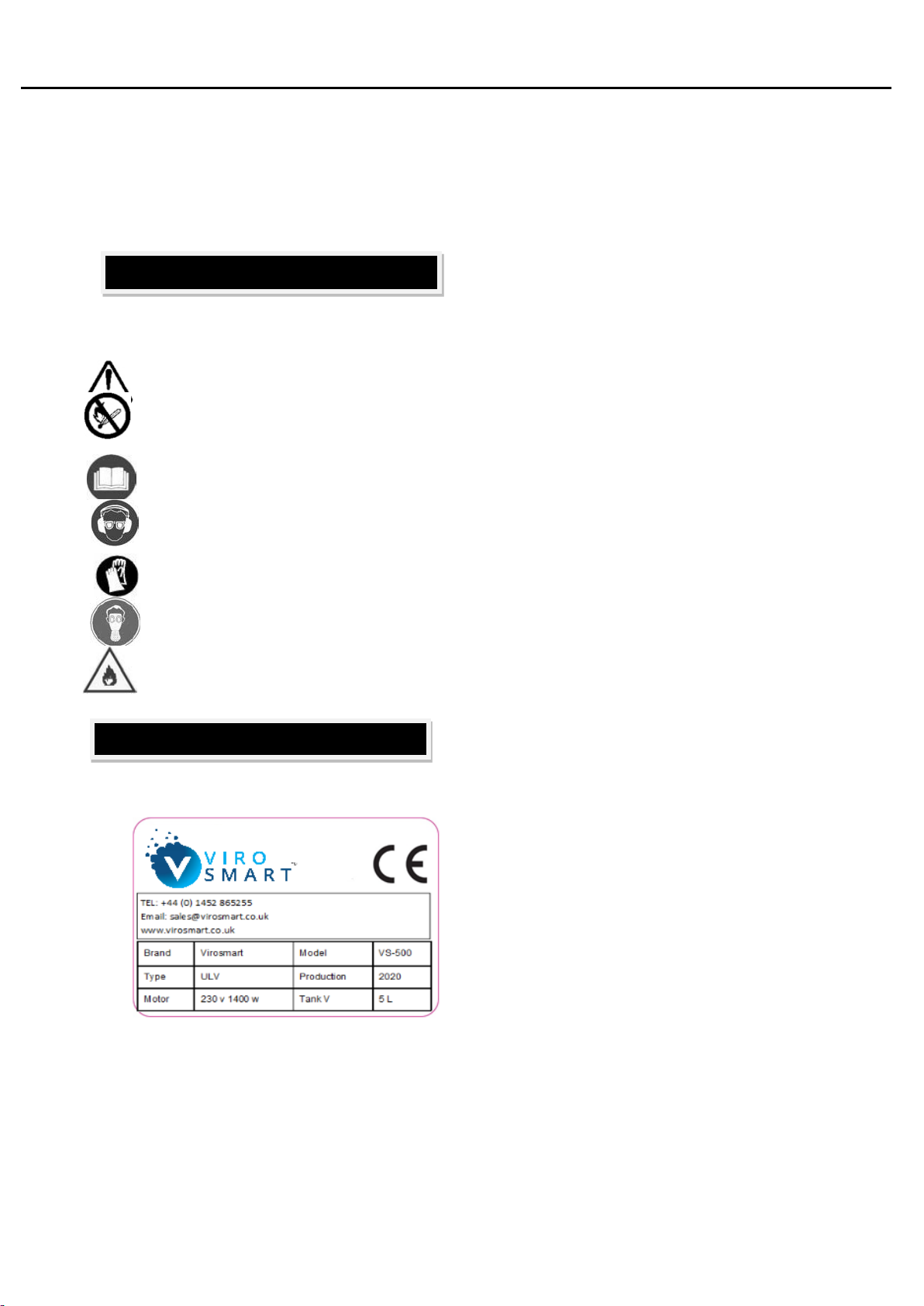

Below symbols have been used in this user and maintenance manual.

Danger –May cause accident and injuries.

Do not approach with flame to the solution store.

Please follow the instructions indicated in the user manual before starting, maintaining or

cleaning the device.

Wear a protective ear-muffs while using.

Wear a protective glove while using.

Wear a suitable mask while the device is running to avoid poisoning.

Chemical used can be inflammable.

Symbols

Labelling

VS-500 ULV Device

User Manual

The most used and given with the device hardware are as below.

2.1. Maintenance and Repair

Repair and maintenance of the VS-500 ULV device shall be performed by qualified and trained

personnel. If you own the ULV device and need your device to be repaired, please follow the

instructions stated in this manual. Please contact Virosmart technical service if you have any

problems or need additional parts, equipment and testing device for your device. Otherwise, your

device will be out of warranty if has a warranty coverage.

2.2. Spare Parts

Virosmart uses quality parts and raw materials for safe operation. Replace parts of the device that are

worn and have completed their lifetime only with equivalent parts. Spare parts you may need during

the warranty period are provided to you by Virosmart. The names and numbers of original parts are

indicated in this user manual. Use original parts for the safety of you and your device. Otherwise, note

that your device will be out of warranty.

2.3. Warranty Period and Conditions

The product you purchased has a year’s warranty against any disruption or dysfunction within the

warranty. Your device is either replaced or fixed within the scope of warranty for manufacturing

defects or faults of us. However, the following items are out of warranty.

- Not using the product in accordance with the instructions indicated in this user and

maintenance manual

- Performing wrong maintenance and repair

- Occurrence of tearing or fraction on device resulting from impact or droppings

- Overutilization of device in a manner to affect the performance limit without a break

- Misuse –Wrong tool use during an incident or maintenance

- Faults occurred due to overheating depending on high contamination at air suction parts

- Wrong use of power

- The maintenance and repair to be made by unqualified and untrained personnel

- Use of spare part other than the original spare part

- It is not suggested to rent out the device, the faults to be occurred due to this reason is also

out of warranty

1. Spare Part

Location

Fluid Tank

For the fluid to be used in the

implementation

Power Plug

Power plug used in countries

Air Filter

Spare of sponge air-suction filter

Manual

In the box

2. SERVİICE SPARE PART AND WARRANTY CONDITIONS

VS-500 ULV Device

User Manual

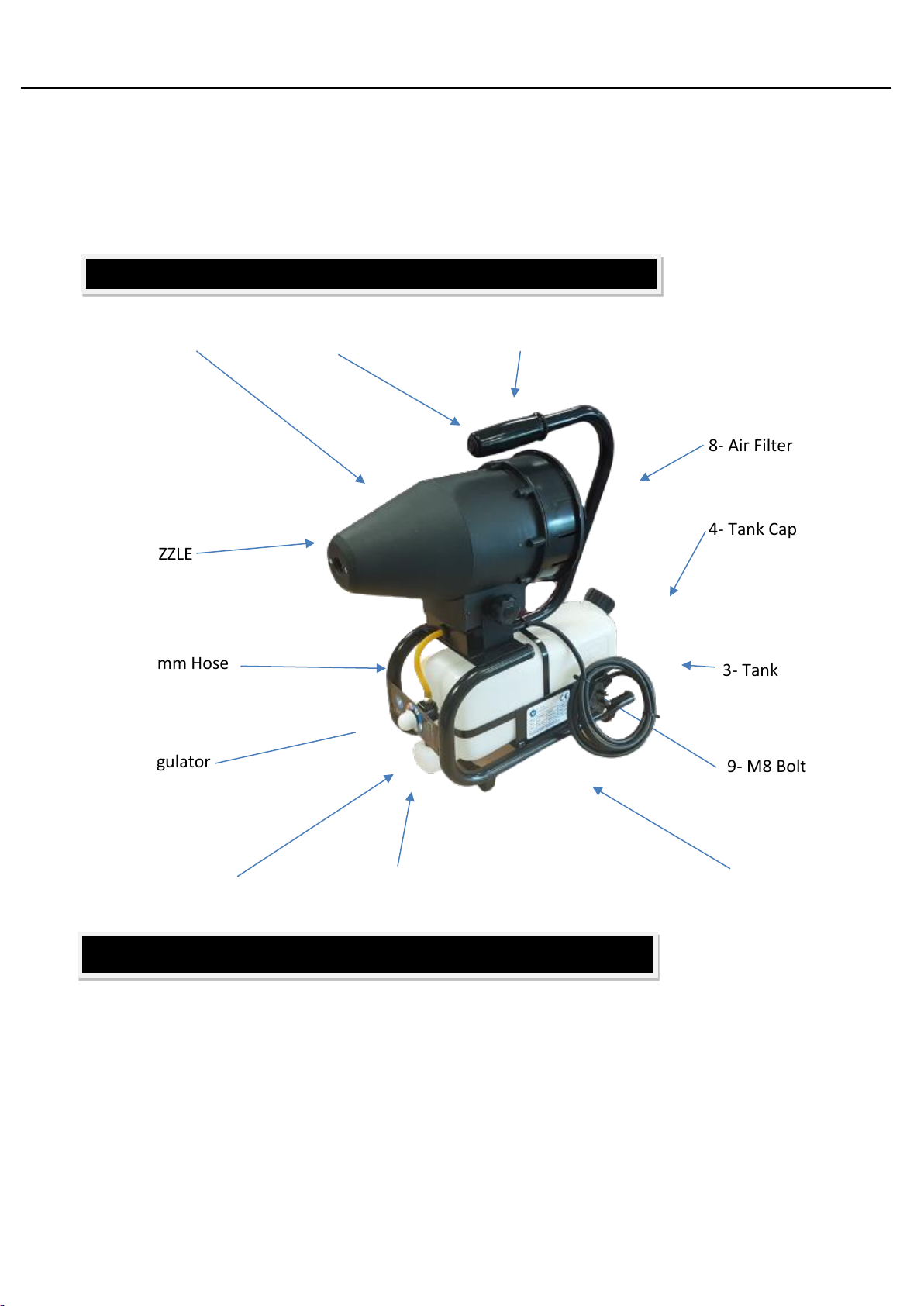

1- Chassis

3- Tank

4- Tank Cap

2- ULV CAP

5- ON-OFF Button

6- HANDLE

8- Air Filter

9- M8 Bolt

2.4. Maintenance Period

Below materials and spare parts need to be replaced periodically.

- Sponge air suction filter (after each use)

- Device cleaning must be performed after each use.

- Clean water must be discharged with a tank cleaning after each use.

4.1. Correct Use - Operation

The device shall only be used in below areas.

- VS-500 ULV device is suitable for air, surface disinfection and fighting against insecticide in

accordance with the regulations determined by international authorities. Follow criteria of fluid

manufacturers while using VS-500 device. Determine the amount to be used depending on the

7- NOZZLE

3. IMPORTANT HARDWARE

10- Regulator

11- 8 mm Hose

4. SAFETY RULES

12- Suction Tube

Suction Seal

VS-500 ULV Device

User Manual

fluid type and brand as suggested by ULV device can be freely used at hospitals, ambulances,

public transports, planes, schools and etc. Follow local provisions before use.

4.2. General Safety Rules

- Some parts of VS-500 ULV device might be disassembled in order to provide space saving

during transportation. For this reason, check if all the parts are available before use.

- Follow the instructions indicated in use-maintenance manual before use of device. Make sure

that the device is connected to a 220 V and earthed power current.

- Operator is responsible for other people while using the device. Do not use the device on

people and animals in public areas.

- Pay attention for no fluid to be poured on the device.

4.3. Protective Equipment for your Safety

While using the device, always use protective clothing and equipment.

- Wear a clothing in a way to cover your whole body, head, eyes and feet. Furthermore, a

protective mask must be used for easy breathing.

- Use gloves.

4.4. Environmental Health

Always care about environmental health.

- Always check for people and animals in the working area and do not use the device in such

case..

4.5. Operation Warnings

- Only one person can use the device, there should not be any other person within 15-20

square meters around the device.

VS-500 ULV Device

User Manual

When any maintenance is needed, please do not forget to stop the device. Please contact with

Virosmart in case of any fault occurred within this user manual. If any spare part replacement is

needed during maintenance, replace only with original parts. Do not ever keep any flame close to the

device during maintenance or assembly. Clean the surface of the device with a wet cloth after each

use.

5.1. Fluid Tank

- Regularly shake fluid tank with clean water and pour the water.

5.2. Air Filter

- Replace sponge air suction filter with the spare filter after each use and dry it after washing

(Only use water)

- Device maintenance should be performed annually in a regular basis and engine should be

checked. (service)

Use 220-230 V 50-60 hz power.

1. Chassis

2. ULV Cap

3. Tank (5 lt. & 10 lt.)

4. Tank Cap

5. On-Off Button

6. Handle

7. Nozzle

8. Air Filter

9. M8 Bolt

10. Regulator

11.8 mm Hose

12.Suction Tube

13.Suction Seal

Make sure all safety measures are taken before turning the device on.

TURNING ON

1. Before turning the device on, take the necessary measures.

2. Fill the fluid necessary for the implementation area to the tank.

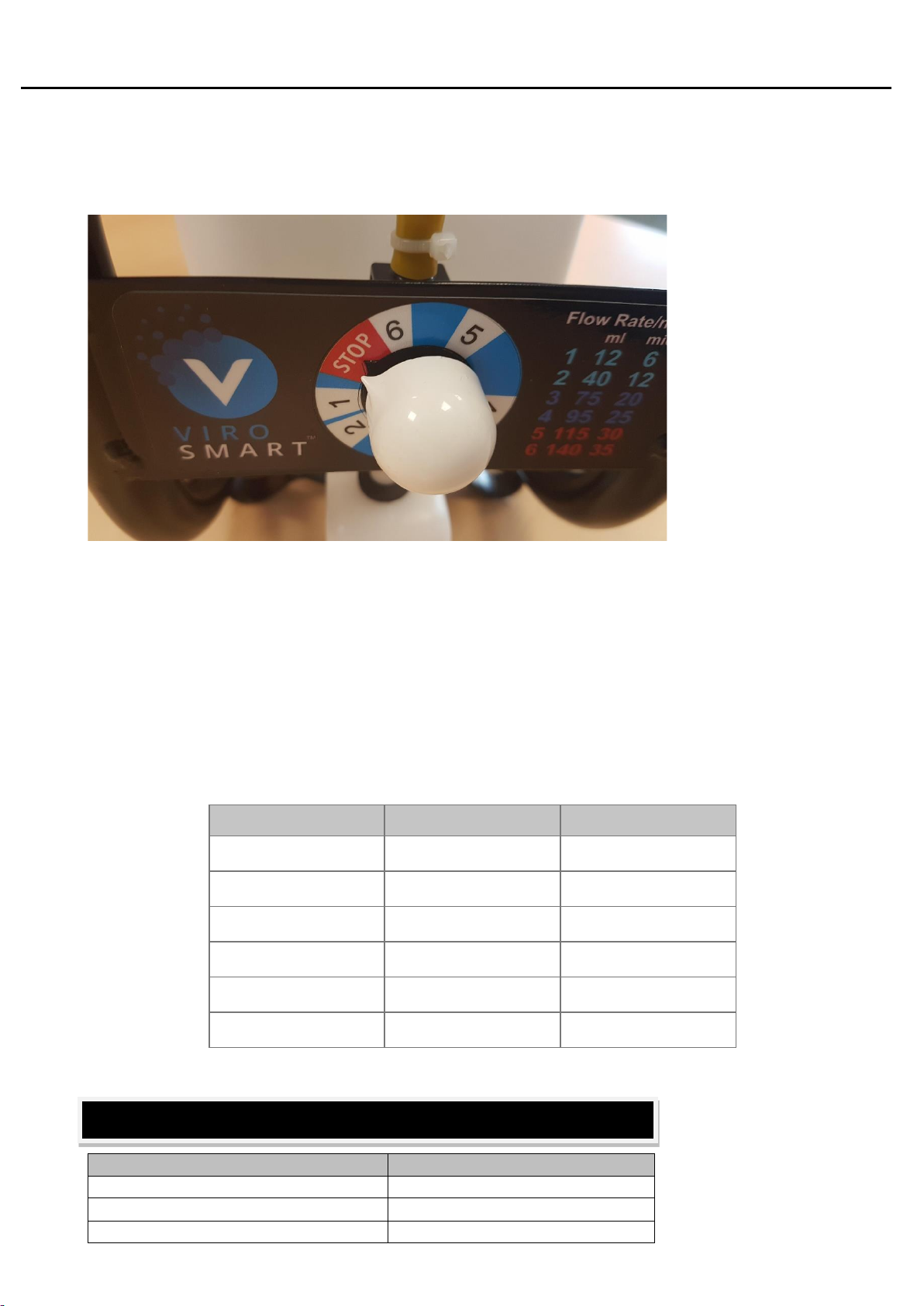

3. You should adjust regulator in accordance with the fluid amount to be used in the area. See

the chart on regulator for information.

4. Ensure you have the appropriate PPE.

5. Switch the On-Off button to “on” position.

6. The device will automatically start.

TURNING OFF

After use Switch the On-Off button to “off” position and turn off at the wall, before removing the plug.

Check the tank, If needed fill up the tank with the suitable disinfectant.

5. Maintenance and Cleaning

6. Power

7. Device Part List

8. Turning On/Off the Device

VS-500 ULV Device

User Manual

1. Use the Debi Regulator (Flow Valve) to set the required micron size –remember to always

return this to the “0” position after use.

•No other persons should be in the vicinity of the machine unless wearing appropriate

PPE. Keep away from children and animals. Objects carried by the air stream can

deflect and injure nearby persons.

•After fogging an additional period of 45 ‐60 minutes is required to allow the droplets to

settle and reduce the risk of operators inhaling thechemical droplets. This time may be

longer or shorter depending on the volume of fog and the particle size. You must

assess carefully before re-entering without PPE.

Be aware of your surroundings

• Watch out for animals which may be within your work area

• Be aware that noise is harmful to the environment. Inquire about and respect possible local rest

periods.

•After each process, add distilled water and start to device to rinse the lines. To Avoid

corrosion.arting/Stopping the de

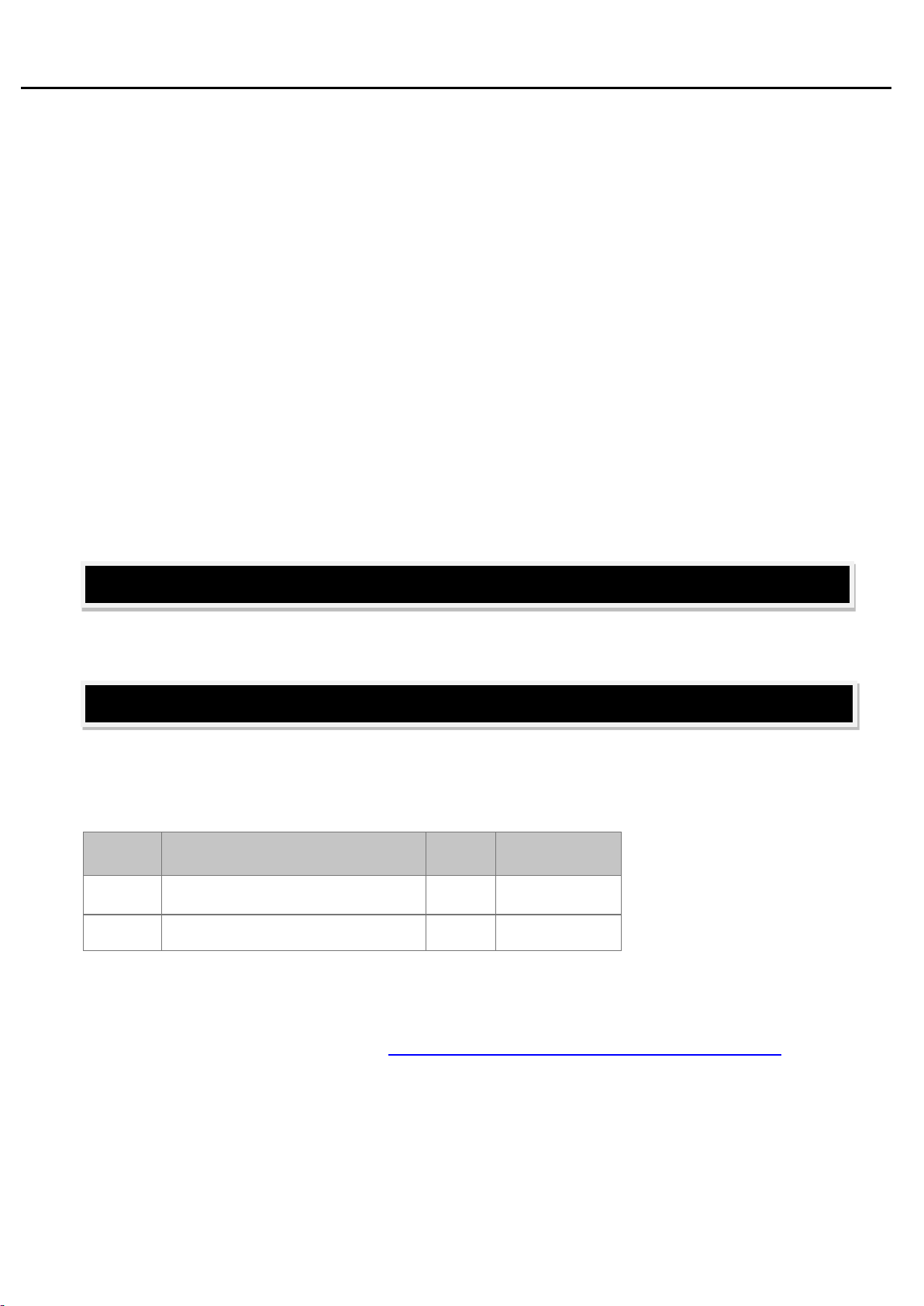

1. Preparing Your Sanitisation Fluid

Dilute Virosmart Virosol at 1:50 according to the table below;

If using an alternative to Virosol ensure you comply with the manufacture’s guidelines.

Use biocides safely. Always read the label and product information before use

For Government guideance on Fogging see http://www.coshh-essentials.org.uk/assets/live/sr03.pdf

Model

Instance

Virosol

Water

VS-500

Regular Fogging

100 ml

5000ml (5

Litres)

VS-300

Regular Fogging

60ml

3000ml (3

Litres)

5. Maintenance and care

7. Operating Guidelines

VS-500 ULV Device

User Manual

2. Setting the Fluid Particle Size and Flow Rate

For internal areas such as offices, domestic properties, and vehicles it is important to use a ‘dry fog’ so as not

to dampen or wet any surfaces or objects. The settings on the dial range between 1 and 6, with each number

corresponding to a micron size and flow rate. The lower the number, the smaller the particle size and the less

the flow rate. A particle size of 20 microns or less is termed as a ‘dry fogging’. However, in areas that are more

sensitive such as offices where there is electronic equipment it is recommended to use a particle size of 12

microns or less.

When fogging areas such as stables or other outdoor environments a larger particle size can be used,

producing a wetter fog. If precipitation occurs when sanitizing, then the particle size is too large –adjust as

necessary to ensure your disinfectant does not begin to drip or run-down surfaces.

Specifications

VS-500

Motor

1400 watt

Spray System

ULV

Fluid Tank

5 l

Dial Setting

Flow Rate (ml / min)

Droplet Size (Microns)

1

12

6

2

40

12

3

75

20

4

95

25

5

115

30

6

140

35

9. Technical Specifications

VS-500 ULV Device

User Manual

Spray Nozzle

1 pcs.

Regulator

Available

Weight

5,40 kg

Sizes (LXWXH)

50x18x50 mm

- Cleaning of fluid tank must be performed periodically after each use. If there is fluid remained, it is

transferred to some other container for the next use. Fluid tank is cleaned by washing with clean

water and made ready for the next use.

Problem

Reason of Problem

Solution Method

Device not working

No power

Check for power.

Power button is off

Turn on the power

button.

Faulty engine

Contact with the service.

Discontinuous Spray

Air intake from suction line

Check suction line and

contact with service.

Not spraying fluid

Regulator settings are off

Make settings.

Fluid suction tube is plugged

Clean the tube.

No fluid in tank

Check fluid.

Implementation ended early

Check settings.

Air filter is highly contaminated

Replace with spare

filter.

IMPORTANT WARNING:

VS-500 Electric ULV device is suitable for spreading fluids (disinfectant, pesticide, perfume, water and

etc.) in the form of aerosol droplets.

10. Discharging Fluid Tank and Cleaning

11. Possible Faults and Solution Methods

Table of contents