2-7

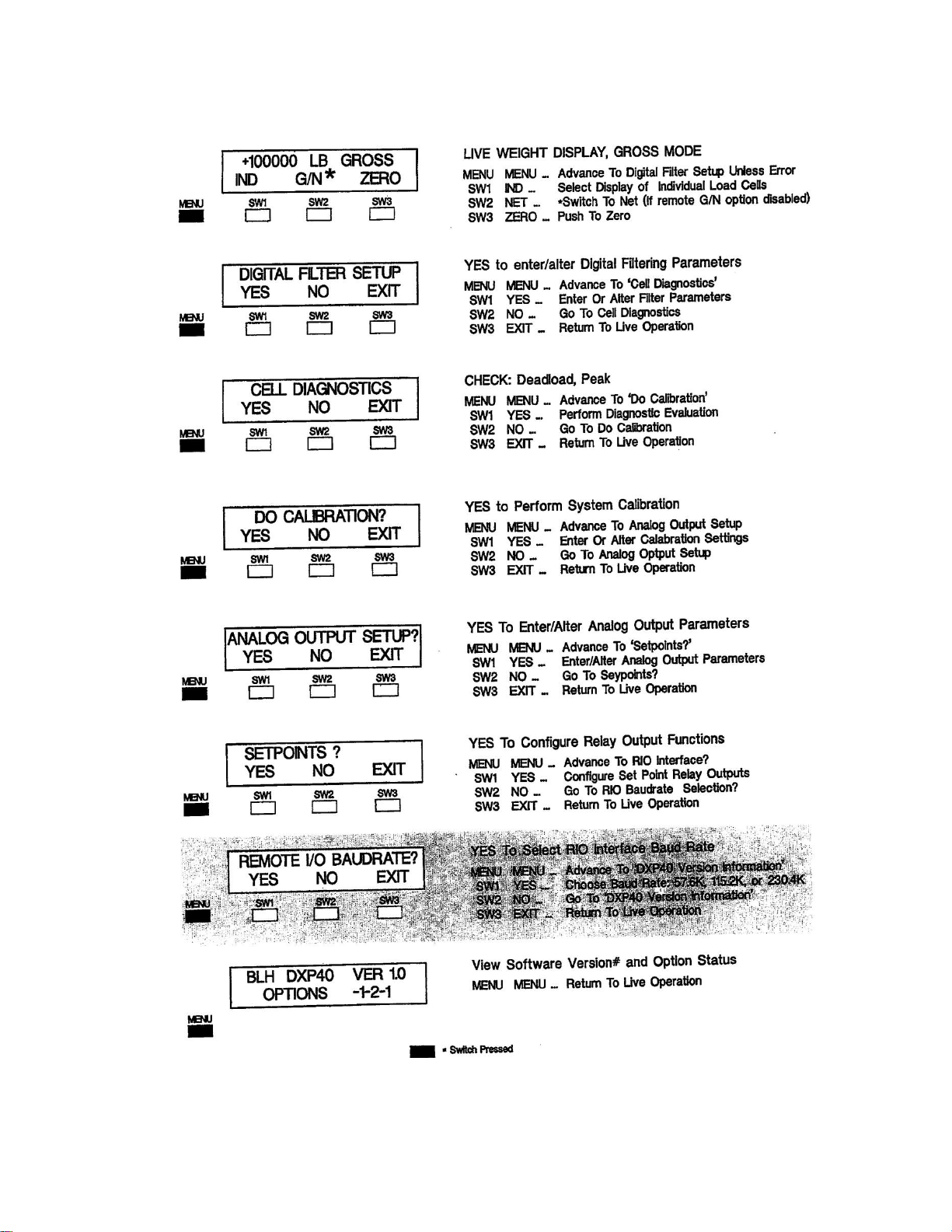

2.4 BLOCKDATATRANSFERS

2.4.1 INTERFACE BASICS

Block data transfers are initiated by the ladder

logic program write (BTW) and read (BTR)

commands. The transfer sequence begins when

the PLC sends the DXp40 a one word (16 bit

integer) write command containing a register

location pointer. This pointer is the 16 bit integer

value of the first register the PLC wishes to read

(factory default upon shipment is register 1).

Table 2-1 presents all available single and

double word register locations. After establishing

the starting register location, the PLC then

transmits a read transfer block command telling

the DXp--40 how many words of information are

needed.

2.4.2 TRANSFER READS (BTRS)

Once

the register location pointer value is

established, the PLC logic program must issue a

block transfer read command to obtain DXp-40

information. A BTR can request up to 64 words

of DXp-40 information (see Table 2-1). The

DXp-40 will respond to the BTR by transmitting

the number of words requested, starting at the

pointer location. NOTE: The first word

transmitted by the DXp-40 will be the register

pointer value. The DXp-40 adds this word at the

beginning of the transmission to 'echo' the

pointer value prior to transmitting requested

data. Therefore, the BTR command MUST add

1 to the number of words requested. If the PLC

needs four words of DXP information, the BTR

request must be for five words (Figure 2-5).

2.4.3 BLOCK TRANSFER WRITES (13-

1111S)

Some of the DXp-40 registers may be written to

by the PLC (indicated by an '" in table 2-1). This

allows parameters such as filter, set point, and

diagnostic values to be down loaded on-the-fly

by the PLC ladder logic program. When writing

to the DXp-40, the first word must be the register

location pointer. Therefore, the program MUST

always add 1 to the BTW command length

(Figure 2-6). For example, to change a set point

value, the BTW length must equal 2 with the first

word being the set point register location pointer

and the second word being the new set point

value. Parameter guidelines for writing data to

the DXp-40 are presented in Table 2-2.

2.4.4 A PERPETUAL POINTER

One advantage to DXp-40 block transfers is that

the register pointer is retained in DXp-40

EEPROM. When a write block selects (points to)

a register location, that location may be

accessed (read) repeatedly without having to re-

write the register location word. Of course the

register pointer can be changed as often as

needed, but the last written location will always

be remembered, even during power down. This

feature saves a lot of BTWs when the PLC is

monitoring a particular register or block of

registers over a period of time.

2.4.5 FAULT EVALUATION

Three status words, register locations 1, 2, and

3, provide detailed explanations of error

conditions encountered by the DXp. When a

fault is detected, either bit 6 (fault) or bit 11

(diagnostic fault) in word 2 of the input image ta-

ble is set to a '1' to alert the PLC of an error

condition. The PLC must then perform a BTR of

the appropriate status register to evaluate and

correctthe error. If bit six (fault) is set, check

status word 3 for the error explanation. If bit 11

(diagnostic fault) is active, check status word 2

and status word 1 bits 12 - 15 for the error

explanation. Table 2-3 gives the status word bit

definitions.

2.4.6 REMOTE FILTER CONFIGURATION

DXp-40 transmitters equipped with the optional

Dynamic Digital Filter can be instructed by the

PLC to change filter settings on-the-fly. This

unique feature allows optimal, pre-determined

filtering parameters to be implemented at critical

moments during a dynamic weigh process.

Changing filter parameters throughout the

process ensures data stability and maximum

system response to actual weight changes.

Filter parameters are stored at register locations

59-70 (Table 2-1). Table 2-2 defines the filter

parameters that can be written to these registers

in the DXp-40. Request BLH technical note TD-

071 for a detailed description of Dynamic Digital

Filtering.