vision microsystems VM 1000 Manual

1

VM 1000

Operator’s Guide

(Excerpts from the VM 1000 Installation, Maintenance, and Operations Manual)

2

PURCHASER / USER AGREEMENT

The purchaser and/or user, by accepting this equipment, agrees to hold

VISION MICROSYSTEMS INCORPORATED, its owners, assigns, heirs and

employees, free and harmless from all loss, liability or damage resulting from claims

brought by any reason of alleged failure or defect of any parts supplied by

VISION MICROSYSTEMS INCORPORATED.

VISION MICROSYSTEMS INCORPORATED has made every effort to document

this product accurately and completely. However, VISION MICROSYSTEMS

INCORPORATED assumes no liability for errors or for damages that result

from the use of this manual or the equipment it accompanies. VISION

MICROSYSTEMS INCORPORATED reserves the right to make changes to this

manual and the product at any time without notice.

VISION MICROSYSTEMS INCORPORATED

4151 Mitchell Way

BELLINGHAM, WASHINGTON 98226

PHONE (360) 714-8203 FAX (360) 714-8253

www.visionmicrosystems.com

3

TABLE OF CONTENTS

1.0 VM1000 QUICK REFERENCE……………..………….....4

1.1 TACHOMETER OPERATION………………………….… 5

1.2 MANIFOLD PRESSURE OPERATION……………..……5

1.3 OIL SYSTEM OPERATION…………………………..……6

1.4 FUEL COMPUTER SYSTEM OPERATION….………....6

1.5 ADDING FUEL TO THE FUEL COMPUTER…………... 7

1.6 FUEL COMPUTER NORMAL OPERATION MODES… 8

1.7 CYLINDER ANALYZER SYSTEM OPERATION…….... 8

1.8 ELECTRICAL MONITORING SYSTEM OPERATION….10

1.9 ‘AUTOTRACK’ ™ SYSTEM OPERATION……………...10

1.10 FLIGHT DATA RECORDER SYSTEM OPERATION… 12

1.11 INDICATOR CARE AND MAINTENANCE……………..12

4

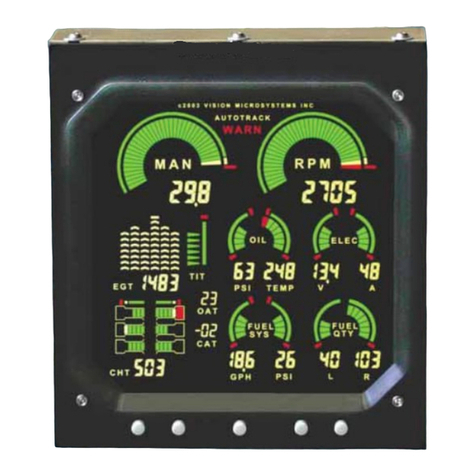

1.0 FIGURE 1: VM1000 QUICK REFERENCE

1 2 3 4 5

BUTTON 1: 'SELECT EGT/TIT GRAPHIC MODES'

BUTTON 2: 'SELECT EGT/TIT & CHT DIGITAL MODES'

BUTTON 3: 'SELECT AUTOTRACK ON / OFF'

BUTTON 4: 'SELECT FUEL COMPUTER MODES'

BUTTON 5: 'SELECT FLIGHT DATA RECORDER INFO'

5

1.1 TACHOMETER OPERATION

The tachometer system provides both a full sweep graphic analog display and four place

digital display. When you start the engine you will see the analog graph rise in proportion

to the engine speed. Full color range marks provide you with a quick reference to monitor

normal, caution and red line engine RPM.

RPM:

The digital readout provides you with exact RPM information. The resolution (or

incremental steps) of the digital display is 10 RPM. For example, the display might read

'2400' and after you make a slight increase in power, it would read '2410'. This is a

definite advantage over other digital tachs that read in less than 10 RPM steps. They

change so frequently that it becomes very distracting and annoying to the pilot. We

recommend using the digital display for RPM checks and letting the engine stabilize for a

minimum of three seconds during the checks. The high accuracy of the tach will allow

you to follow long-term performance trends of your engine and prop, such as static

maximum rpm, carb heat effectiveness, and typical mag drops. These can be important

indicators of engine and accessory condition.

Engine Operating Hours:

Another feature is the 'engine hours counter'. When the engine is off, the digital display

reads the total accumulated engine hours to a maximum of '5999.9'. Engine hours are

accumulated any time RPM is greater than 1500.

RPM Alert:

A warning alert activates whenever the engines redline is reached. The RPM display will

flash until this condition is corrected.

1.2 MANIFOLD PRESSURE OPERATION

The manifold pressure system provides both a full sweep graphic analog display and

three place digital display.

The full sweep graphic display resolution is 1" IN. HG. The full color range marks provide

you with a quick reference to manifold pressure when making fast power changes.

The digital readout provides you with precise manifold pressure information. This allows

very precise power settings to be achieved.

You can, for example, in stabilized conditions, watch for small changes in pressure that

can indicate throttle creep or induction problems.

For new induction system designs, or modifications to existing designs, this repeatability

is extremely valuable to judge the performance of the design or design changes.

Manifold Pressure Alert:

A warning alert activates whenever the engines redline is reached (typically only for

turbocharged engines). The display will flash until this condition is corrected.

6

1.3 OIL SYSTEM OPERATION

Both oil pressure and oil temperature are displayed continuously in two separate full

sweep graphic and digital areas.

Oil Pressure:

As oil pressure rises, the graph size increases proportionately. The full color range marks

let you see at a glance how close to red line oil pressure you are.

The digital display reads out in 1 PSI increments to a maximum of 99. This is very useful

for monitoring typical engine oil pressure trends. Because of the high accuracy and

repeatability of this system, the oil pressure can be closely monitored for unusual trends.

For example, if you are cruising in a stabilized condition, and the oil pressure starts to

count down, and oil temp is counting up, this could help you to identify impending oil-loss

or cooling problems.

Oil Pressure Alert:

A warning alert activates whenever the engines redline is reached. The display will flash

until this condition is corrected.

Oil Temperature:

Oil temperature is displayed both graphically and digitally. As oil temperature rises, the

graph size increases proportionately. This is consistent with the oil pressure display and

makes it very easy to determine relationships between the two parameters.

The full color range marks let you see at a glance how close to red line oil temperature

you are.

The digital display reads out in 1 degree Fahrenheit increments to a maximum of 300

degrees. This is very useful for monitoring typical engine oil cooling system performance.

For new engine installations, you can take advantage of the high accuracy and

repeatability for analyzing the engine oil cooler system efficiency. If the cooling does not

seem to be effective enough, you can make changes and repeat your tests with the

confidence that the next test data will reflect the results of your changes.

Oil Temperature Alert:

Your oil temp system also provides you with built-in warning annunciators. If the oil

temperature rises above redline, the system captures the event and the display is flashed

until the problem is corrected. This is a real advantage in the busy cockpit.

1.4 FUEL COMPUTER SYSTEM OPERATION

Fuel Pressure:

Fuel Pressure is displayed both digitally and graphically. As fuel pressure rises, the graph

rises proportionately. Full color operating range marks are provided that indicates the

normal operating range of fuel pressure for your engine at a glance. The digital display

allows you to see small variations and make notations of typical fuel pressure behavior.

7

Fuel Pressure Alert:

The system has a built-in warning system and will flash should fuel pressure move

outside of the limits for your particular engine.

Fuel Flow:

Fuel Flow is displayed both digitally and graphically. As fuel flow increases, the graph

increases proportionately. The digital display provides tenth gallon resolution.

There are four additional features that the fuel computer provides:

'REM' - Fuel remaining onboard

'BRN' - Fuel burned since last power-up

'HRS' - Hours of fuel remaining

'ADD' - Add fuel to computer memory.

An exclusive feature of our fuel flow computer is its ability to 'damp out' the wide

variations in displayed fuel flow normally seen on other fuel flow digital readouts. Our

system will smooth these short term flow variations to give you a steady flow indication

with NO sacrifice in accuracy.

Fuel Remaining Alert:

Your fuel computer has a built-in 'Low Fuel Remaining' warning annunciator. When the

computed fuel total is less than a factory programmed amount (10 gallons standard), the

display will flash.

1.5 ADDING FUEL TO THE FUEL COMPUTER

***************************** WARNING *********************************

IMPROPER USE OF THIS FEATURE WILL GIVE YOU INCORRECT FUEL 'REM' AND

‘HRS’ INFORMATION. INSURE THAT YOU UNDERSTAND THE OPERATION OF

THIS SYSTEM BEFORE USING IT INFLIGHT. AFTER INSTALLATION AND

PERIODICALLY THEREAFTER, VERIFY THAT THE SYSTEMS ACCURACY IS

ACCEPTABLE FOR YOUR INTENDED USE.

****************************************************************************

Your fuel computer has a unique feature that allows you to 'ADD' fuel according to how

much has been pumped into the tank(s). You are not required to calculate the new total

fuel level after adding fuel, as on many other fuel computers. This system does it for you.

Follow the steps below to 'ADD' fuel to the computer, referring to 'Error! Reference

source not found.’:

STEP 1. Press 'BUTTON 4' until the 'ADD' indicator activates

STEP 1. Press 'BUTTON 3 to add tens and 'BUTTON 5' to add ones to match the fuel

that was pumped into the tank(s).

NOTE: To 'top off' the tank(s) just press 'BUTTON 3' to run up a number more

that your max capacity. The system will only add what is needed to 'fill' the

computers electronic tank to its max capacity as set up in 'Error! Reference

source not found.'.

8

STEP 2. If you made a mistake just leave everything alone for more than 20 seconds

and the computer will automatically cancel the ‘ADD’ mode. If you are happy

with the entered value, then press 'BUTTON 4' and the new fuel will be

automatically added to the prior fuel ’REM’ total. Double check this new total

by pressing 'BUTTON 4' until the ‘REM’ fuel is shown.

NOTE: In the event you want to ‘zero’ the current fuel remaining value, press Button 4

until ‘REM’ is displayed and continue holding it in. Simultaneously press Button 3 and the

‘REM’ value will be cleared to zero.

1.6 FUEL COMPUTER NORMAL OPERATION MODES

Press 'BUTTON 4' to select the desired fuel computer operating mode. The mode is

displayed below the permanent words 'FUEL FLW' on the display:

‘FUEL FLW’: Fuel Flow is the default mode after powering up. This mode displays the

fuel flow in the appropriate Units Per Hour both digitally and graphically. The digital

section provides 0.1 unit resolution. The graphic section provides you with a quick

reference of the current fuel flow.

‘REM’: This mode displays the current fuel total remaining in gallons. It is digitally

displayed in 0.1 gallon increments. This mode is ONLY usable, if you have kept the

computer's memory updated with fuel information corresponding to the actual aircraft

usable fuel and have always had the computer operational when fuel is being burned.

The graphic display is shut off as it has no relationship to this parameter.

‘HRS’: This mode displays the calculated hours of fuel remaining (sometimes referred

to as endurance), as a function of the current flow rate and current fuel total in the

computer's memory. It is digitally displayed in 0.1 hour increments. This mode is ONLY

usable, if you have kept the computer's memory updated with fuel information

corresponding to the actual aircraft usable fuel and have always had the computer

operational when fuel is being burned. The graphic display is shut off as it has no

relationship to this parameter.

‘BRN’: This mode displays the gallons of fuel burned in flight since system power up. It

is digitally displayed in 0.1 gallon increments. The graphic display is shut off as it has no

relationship to this parameter.

‘ADD’: This mode allows you to add fuel to the fuel computers 'electronic tank' after fuel

has physically been added to the aircraft's tank(s). See section on 'ADDING FUEL TO

THE COMPUTER'.

1.7 CYLINDER ANALYZER SYSTEM OPERATION

The engine analyzer system displays all cylinder information both graphically and

digitally. Full color reference marks are provided for cylinder head green, yellow and

redline temperatures.

9

‘DIAMOND GRAPH‘ DISPLAY MODES:

'GRAPHIC MODE 1' (ABSOLUTE EGT): Press 'BUTTON 1' once (if in GRAPHIC MODE

1) to activate. All four graphs in the upper area come on and display absolute EGT

temperature. This mode is most useful to spot plug / injector or valve problems. Each bar

equals +50 deg. F with the base beginning at 1300 deg. F.

'GRAPHIC MODE 2' (RELATIVE EGT MODE) Press 'BUTTON 1' again (if in GRAPHIC

MODE 2) to activate. All four graphs, plus two brackets, in the upper area come on and

display RELATIVE EGT temperatures. This mode is most useful to watch short-term

behavior of EGT to spot plug / injector or valve problems or when leaning to peak EGT.

Each bar equals +20 deg. F with the bases normalized when the mode was activated.

DIGITAL DISPLAY MODES:

The digital displays shows individual temperatures for EGT and CHT. Periodically

messages such as 'E1 C1' appear to show which probes you are viewing digitally

(ex.1: 'E1 C1' means 'E'GT 1and 'C'HT 1are in view; ex. 2: 'P1 H4' means 'P'eak

EGT 1(hottest) and 'H'ottest CHT 4 are in view).

The digital display defaults to the hottest CHT. For example, if CHT 1 is the hottest, the

digital display will show H1 periodically. Pressing button 2 will cycle through each CHT

and the hottest and allow you to select a different CHT by choosing C1, C2 etc. After

the unit is turned on, the digital display defaults to show the hottest CHT. Temperature

is displayed in Fahrenheit units.

Additionally, warning messages are shown if a cylinder has reached 'red line'

temperature (ex: 'H2' for hot cylinder 2), or is being 'shock cooled' (ex: 'C3' for cold

cylinder 3).

You can select a digital view by successively pressing 'BUTTON 2' :

Digital Mode # Digital View Cyl. Numbers

1 Cyl. 1 EGT & CHT 'E1' 'C1'

2 Cyl. 2 EGT & CHT 'E2' 'C2'

3 Cyl. 3 EGT & CHT 'E3' 'C3'

4 Cyl. 4 EGT & CHT 'E4' 'C4'

5 Hottest EGT & CHT 'Pn' 'Hn'

After powering up the unit, the EGT digital display defaults to EGT 1 Periodically the

digital display will identify which EGT you are seeing by showing and E followed by the

EGT number, such as E1 for EGT 1. After you have successfully leaned the engine (as

an example, lets assume it was EGT 2), the digital readout is locked to that EGT and E1

will change to P2 signifying that it peaked on EGT 2. Tap button 2 to select a different

EGT by choosing E1, E2, E3 etc. (Note: not available when in the peak mode).

Temperature is displayed in Fahrenheit units.

10

LEANING YOUR ENGINE:

*************************** WARNING ******************************

REFER TO YOUR ENGINE OPERATING MANUAL FOR THE PROPER

TECHNIQUES, TEMPERATURE AND PRECAUTIONS FOR LEANING. STEPS

BELOW ARE SUGGESTED ONLY !

************************************************************************

STEP 1: STABILIZE; the aircraft engine temps, throttle, rpm and insure mixture is on

the rich (cooler) side temperature (approximately 100 Deg F cooler ) of max EGT.

To verify this, enrichen mixture to see that ALL EGT values decrease.

STEP 2: LEAN; the engine mixture smoothly to start the EGT bars climbing (about one

bar per 2 seconds). Lean so as not to exceed max EGT. (See your engine manual

for proper recommended operation). The digital readout should be showing either

'P1' or 'P2' indicating which EGT is hottest. Use this digital display to monitor and

fine tune the EGT temperature according to your engine operating manual.

1.8 ELECTRICAL MONITORING SYSTEM OPERATION

VOLTAGE is displayed both graphically and digitally. Full color range marks provide a

quick reference for fast analysis of voltage levels. As voltage rises, the graph size

increases proportionately.

Additionally your system has a built-in warning system that flashes the graph when

system voltage is out of nominal range (either too low or too high) .

AMPERAGE is displayed both graphically and digitally. Full color range marks provide a

quick reference for fast analysis of amperage levels. As amperage rises, the graph size

increases proportionately.

The digital readout displays amperage at 1 amp resolution. This is useful for

troubleshooting.

The amp system functions as an 'alternator load meter' displaying current flow FROM the

alternator TO the aircraft electrical system allowing you to see if a load (such as pitot

heat) is really drawing current when turned on. You should see an increase on the amp

display when you turn on a load, such as pitot heat for example. This tells you that the

pitot heater is drawing power and is probably OK. By verifying that voltage remains the

same, then it can be assumed that the alternator is supporting the additional load. A very

handy feature for in-flight testing / verification of electrical loads and the alternator

charging system.

Additionally your system has a built-in warning that flashes the graph and triggers the

audio/visual annunciator system (if installed) when the alternator does not produce power

for the electrical system. This occurs at low amperage levels of approximately less than 2

amps.

1.9 ‘AUTOTRACK’ ™ SYSTEM OPERATION

The 'Autotrack' system is a breakthrough in modern engine monitoring technology.

Designed to reduce the pilot's workload by assisting in the tedious and often overlooked

11

job of monitoring engine parameters for deviations from one minute to the next,

'Autotrack' adds a new level of safety to engine management.

Subtle changes may occur in engine parameters that can precede major problems.

These changes are often missed by even the most attentive of pilots. 'Autotrack' alerts

you to these changes allowing you to analyze the situation and take appropriate action.

WHEN TO USE 'Autotrack':

•Climb - Activate during climb to alert you periodically as CHT increases and to a

decrease in manifold pressure.

•Cruise - Activate during cruise to alert you if any parameter begins to drift from your

selected starting point.

•Descent - Activate during descent to alert you to increasing manifold pressure and

rising EGT due to a leaning mixture.

HOW TO USE 'Autotrack':

STEP 1. STABILIZE the aircraft. Set up your desired power and mixture condition. Allow

the engine time to stabilize (i.e., engine temps and pressures, etc.).

STEP 2. Press 'BUTTON 3'. The 'Autotrack' indicator will activate in the display and the

system will begin tracking the engine's performance from this point.

The 'Autotrack' system is now armed and watching for engine deviation from the point you

picked. To cancel, simply press 'BUTTON 3' again to extinguish the 'Autotrack' indicator.

Re-arm again at any time.

NOTE: Any important alert condition, (i.e., low fuel pressure, high CHT, etc.)

automatically cancels 'Autotrack' mode.

'Autotrack' ALERT INDICATIONS:

If any engine parameter deviates beyond the initial set point, the system will flash the

corresponding graphic display and the 'AUTOTRACK' indicator.

If the deviation is large enough, a graphic pointer (circular sweep displays only) will

show where the parameter was before the deviation occurred. This gives you a chance

to evaluate the magnitude of the deviation and take the appropriate action.

To shut off the alert condition, return the parameter to its previous value (example:

adjusting manifold pressure due to a climb) or simply press 'BUTTON 3' to shut off the

'AUTOTRACK' system.

If optionally equipped, an audible and visual alert will activate in the EC100 caution

advisory system.

12

1.10 FLIGHT DATA RECORDER SYSTEM OPERATION

The Flight Data Recorder System comes standard with your VM1000 and is designed to

allow you to review / record the performance of the engine and systems during each flight.

This is extremely valuable during initial flight testing and for subsequent trend analysis.

You may retrieve data using the Flight Data Recorder at any time during the flight or even

after the aircraft has been shut down for a prolonged period of time.

Minimum and maximum values are automatically recorded during the flight and can be

reviewed at any time before the next flight. Taxi data is automatically omitted, as this info

is generally not important. Actual time of flight is also recorded.

HOW TO USE 'Flight Data Recorder':

STEP 1. Press 'BUTTON 5'. The first set of data are flight minimums encountered (i.e.,

lowest fuel pressure, lowest voltage, amperage, etc.). Also the RPM digital

display now shows the actual flight hours and tenths.

STEP 2. Press 'BUTTON 5' again. The next set of data are flight maximums encountered

(i.e., max CHT, max Oil Temp, max RPM, etc.).

STEP 3. Press 'BUTTON 5' again. The Flight Data Recorder is shut off. The recorder

data will automatically shut off in approximately 20 seconds if no button is

pressed.

1.11 INDICATOR CARE AND MAINTENANCE

The indicators require no scheduled care or maintenance. However, you probably will

want to clean them occasionally. We recommend the use of diaper flannel. NEVER use

paper towels or tissues, as they can have a high abrasive content.

To properly clean your indicator, remove surface dust and abrasives by blowing on the

indicator face or brushing with a soft bristle brush. Next, 'fog' the indicator with your

breath and gently rub the indicator. NEVER use any solvents or cleaning fluids on

the indicators.

Other manuals for VM 1000

1

Table of contents

Other vision microsystems Measuring Instrument manuals