Vislink AFD120 Ku User manual

TECHNICAL OPERATION HANDBOOK

For

The Document is supplied on the express terms that it is to be

treated as confidential and that it may not be copied, used or

disclosed to others for any purpose except as authorised by

Vislink.

ADVENT COMMUNICATIONS

Vislink House

27 Maylands Avenue

Hemel Hempstead

Hertfordshire

HP2 7DE

England

Telephone: National 01442 431 300

Fax: 01442 431 301

24 Hour Support +44 (0)1442 431 410

Advent Communications is a brand name of Vislink International

ADVENT FLYDRIVE 120-150 ANTENNA

Document No. 209293 Rev. A

VISLINK

Flydrive 120-150 Antenna

This page left intentionally blank

VISLINK

Flydrive 120-150 Antenna i

CONTENTS

AMENDMENT RECORD SHEET 1

EMC DECLARATION 2

WARNINGS AND HAZARDS 3

ADDITIONAL SAFETY INFORMATION 4

STOWAGE WARNING 4

1.ANTENNA 5

1.1INTRODUCTION 5

2.SPECIFICATION 6

2.1RF 6

2.2DRIVE CONTROL UNIT 7

2.3MECHANICAL 8

2.4ENVIROMENTAL SPECIFICATION 9

3.OPERATING PROCEDURE 10

3.1ANTENNA ASSEMBLY – FLYAWAY CONFIGURATION 10

3.2ANTENNA ASSEMBLY – ROOF RACK MOUNT CONFIGURATION 12

3.3MANUAL OPERATION 13

3.4ANTENNA STOW CONFIGURATIONS 14

3.5OFFSET SATELLITE ADJUSTMENT 18

3.6DRIVE CONTROL UNIT 18

4.FLYDRIVE MAINTENANCE 19

4.1DISH 19

4.2AZIMUTH WORM GEAR 19

4.3POLARISATION DRIVE 19

4.4CABLES 19

4.5FEEDHORN WINDOW 19

4.6FLEXIBLE WAVEGUIDE 19

4.7ALL SCREWS/BOLTS 20

4.8RADIATION CHECK 20

5.ASSEMBLY IMAGES 21

6.WARRANTY 32

6.1WARRANTY INFORMATION 32

6.2CLAIM FOR DAMAGE IN SHIPMENT 32

6.3FIELD SERVICE 32

6.4SHIPMENT OF REPAIR PARTS TO FIELD 32

6.5RETURN PROCEDURES 32

6.6TRANSPORTATION AND PACKAGING 33

6.7AUTHORISATION FOR EVALUATION 33

7.FIGURES 34

FIGURE 1 – FLYDRIVE 120 CONFIGURATION – 402693 34

FIGURE 2 – FLYDRIVE 120 ROOF RACK MOUNT CONFIGURATION – 402692 34

FIGURE 3 – FLYDRIVE 120 PETAL CASE IN SUB 32 KG CONFIGURATIONS – 402690 35

FIGURE 4 – FLYDRIVE 150 FLYAWAY CONFIGURATION - 403080 36

FIGURE 5 – FLYDRIVE 150 ROOF RACK MOUNT CONFIGURATION - 403080 36

FIGURE 6 – FLYDRIVE 150 PETAL CASE IN SUB 32 KG CONFIGURATIONS 402691 37

FIGURE 7 – FLYDRIVE 150 ANTENNA STOWED - 403080 37

FIGURE 8 – SATELLITE GEOMETRY 38

VISLINK

Flydrive 120-150 Antenna ii

This page left intentionally blank

VISLINK

Flydrive 120-150 Antenna 1

AMENDMENT RECORD SHEET

ISS DATE ECR DESCRIPTION OF CHANGE AUTHOR

1 02/2007 N/A New N/A

2 03/2007 N/A Add assembly images. N/A

3 07/2007 N/A Add Flydrive 150 details. N/A

4 08/2008 N/A Add 150 petal assembly order. N/A

5 09/2008 N/A Revised elevation limit. N/A

6 07/2009 N/A Add DC brake input details, change first aid

notes. JM

7 09/2009 N/A Page 41 added. JM

8 25/11/2013 N/A Updated SC

A 16.04.14 N/A Documents RD000431 & 209349

incorporated, case content photos added FGL

VISLINK

Flydrive 120-150 Antenna 2

EMC DECLARATION

VISLINK

Flydrive 120-150 Antenna 3

WARNINGS AND HAZARDS

FAILURE TO OPERATE AND USE THE EQUIPMENT OTHER THAN INSTRUCTED IN

THE MANUAL MAY RESULT IN ELECTRIC SHOCK.

HAZARDOUS WARNING LABELS

NON-IONISING RADIATION

CAUTION – HEAVY ITEMS

CAUTION – MOVING PARTS

TEST/ALIGNMENT OF UNITS FITTED WITH AC/DC POWER SUPPLY

UWARNINGUHazardous voltages are present with lid removed

Diagnostic work on AC powered units or PCBs must be carried out in a test area designated

and equipped for live testing. If units have recently been in operation, time must be allowed

for the discharge of capacitors before handling the unit.

Hazardous AC voltages present

Possible source of radiation hazard, normally

located at waveguide connections, waveguide

joints and antennas.

During operation of the antenna

there will be moving parts; do not

touch whilst in motion

Some items of equipment may weigh

in excess of 25kg, do not attempt to

move or lift without assistance

VISLINK

Flydrive 120-150 Antenna 4

ADDITIONAL SAFETY INFORMATION

Most of the microwave energy

is contained within this beam

Close Up View

Far View

The European Standard that defines power levels is ETS300327.

The microwave power density limit is 10w/m sq.

For a 125w amplifier and 1.2m antenna, the shaded area represents power levels above the

limit. Outside of this area, the power level is below the limit.

This example shows the beam at 21 deg elevation.

The distance R (m) is approximately

R = antilog (eirp/20 - 1.05) where eirp is dBw.

STOWAGE WARNING

If the Flydrive antenna is fitted to a vehicle, ensure that it is stowed when the vehicle is in

motion. The antenna has not been designed to be deployed in this condition and the

resulting forces may exceed the design criteria.

Care should be taken that nothing obstructs the antenna when it is moving as injury or

damage to the antenna or its surroundings may result.

VISLINK

Flydrive 120-150 Antenna 5

1. ANTENNA

1.1 INTRODUCTION

The Flydrive Motorised Antenna System is a highly compact satellite earth terminal, capable

of operating with most of the geostationary C, X, Ku, DBS and Ka band satellites, which are

currently in orbit or are planned.

Its function is to transmit TV programming and communications and to be capable of

monitoring its own transmissions from many sites around the world.

The system has been designed to be used as a flyaway antenna or is able to be fitted to a

standard vehicle roof rack without any modifications to either the antenna or vehicle.

The antenna may be packed in two configurations to allow either quick deployment or case

weights to be under 32kg to comply with the IATA weight restrictions for air travel.

The Antenna Control Unit allows the operator to deploy or stow the antenna with minimum

effort from within the operator’s environment.

The elevation and azimuth backup handle is stowed within the main antenna cases.

VISLINK

Flydrive 120-150 Antenna 6

2. SPECIFICATION

2.1 RF

Type Segmented circular

Diameter 1.2m or 1.5m

Configuration Offset

Mount Elevation over Azimuth

Frequency

Tx C-Band 5.85-6.650 or 6.725-7.025 GHz

X-Band 7.9-8.4 GHz

Ku-Band 13.75-14.50 GHz or 12.75-13.25 GHz

DBS-Band 17.3-18.1 GHz (optional 18.4GHz)

Ka-Band 27.5-30.0 GHz or 30.0 to 31.0 GHz

Rx C-Band 3.7-4.2 or 4.5-4.8 GHz

X-Band 7.25-7.75 GHz

Ku-Band 10.70-12.75 GHz

DBS-Band 10.70-12.75 GHz

Ka-Band 18.0-22.0 GHz

1.2m 1.5m

Gain dBi Tx C-Band

Tx X-Band

Tx Ku-Band

Tx DBS-Band

Tx Ka-Band

-

-

Defined at

the OMT

flange

Rx C-Band

Rx X-Band

Rx Ku-Band

Rx DBS-Band

Rx Ka-Band

WG loss C-Band 0.35 dB

Ku-Band 0.65 dB

Off-axis gain Tx 29-25 log100/D < 0 < 20°.

-3.5 20 < 0 < 26.4°.

32-25 log26.4 < 0 < 48°.

Rx

32-25 log100/D < 0 < 48°.

Polarisation Linear-orthogonal (C, Ku, DBS and Ka)

Circular (C, X and Ka)

Cross polar isolation -35 dB rel co-polar gain within 0.2deg

(Ku and DBS)

VISLINK

Flydrive 120-150 Antenna 7

VSWR

Tx Rx

C 1.2:1 1.3:1

X 1.4:1 1.35:1

Ku 1.2:1 1.3:1

DBS 1.3:1 1.5:1

Ka 1.3:1 1.3:1

Port/Port isolation

C TX/RX: 40 dB (110dB incl filter)

RX/TX 30 dB

X TX/RX 20 dB (100dB incl filter)

Rx/Tx 20 dB

Ku TX/RX 40 dB (110dB incl filter)

Rx/Tx 30 dB

DBS TX/RX 40 dB (110dB incl filter)

Rx/Tx 30 dB

Waveguide Flanges Advent Q/R Flange and:

C-Band CPR137

X-Band UBR84/CPR112

Ku-Band UBR120

DBS-Band UBR140

Ka UBR320/UBR220

Feed 2 port (3,4 port optional)

Power (RF) 500w cw

2.2 DRIVE CONTROL UNIT

Antenna Limits

Polarisation ± 95°

Azimuth -200° to +200°

Elevation 6° to 92°

Display

Resolution 0.1°

Power

Power Connector 3 Pin IEC plug with dual fusing

AC Supply 90-264V AC. (47-63Hz)

Consumption < 100VA

VISLINK

Flydrive 120-150 Antenna 8

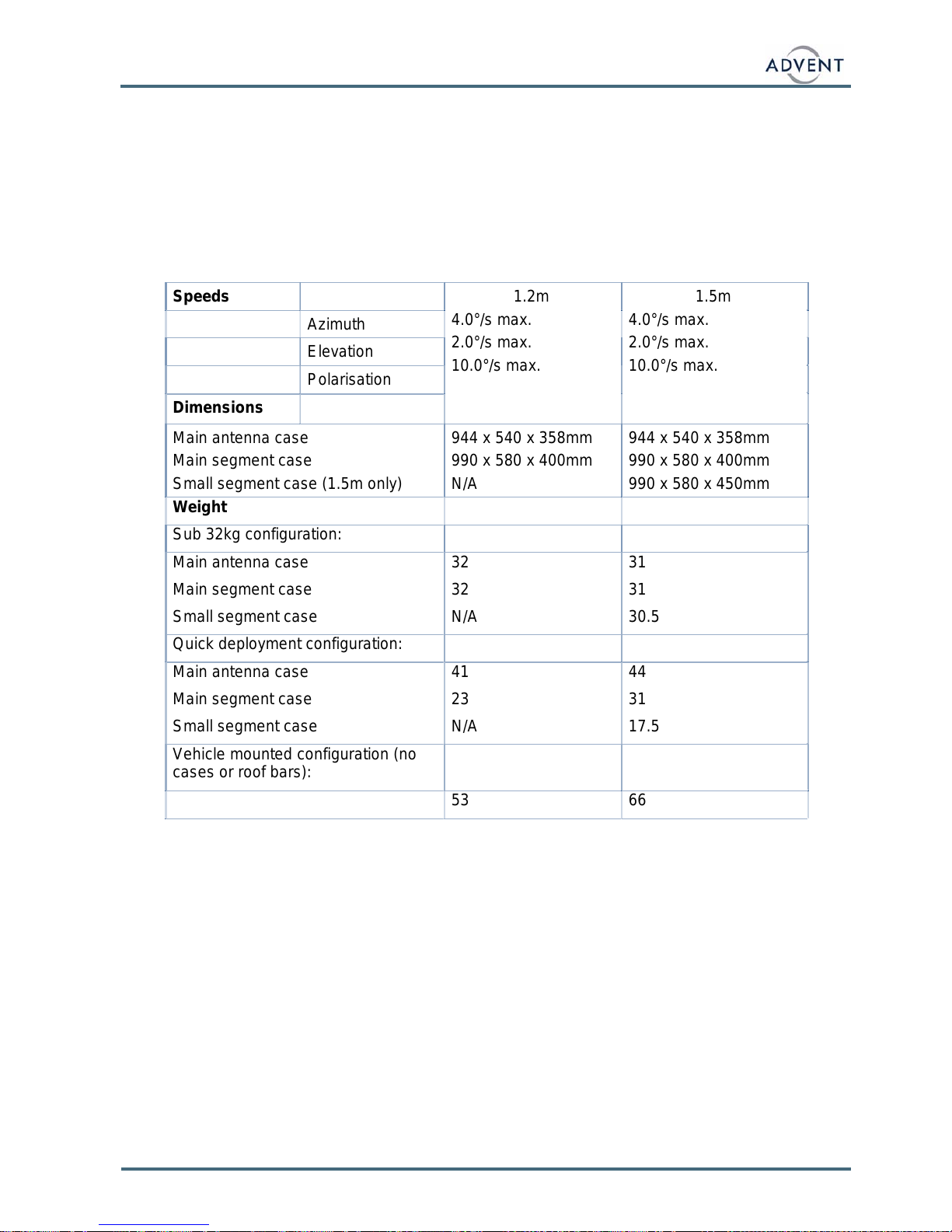

2.3 MECHANICAL

Azimuth adjustment ± 200°

Elevation adjustment 6° to 92°

Pol. Adjustment ± 95°

Motorisation Azimuth

Elevation

Polarisation

Speeds 1.2m

4.0°/s max.

2.0°/s max.

10.0°/s max.

1.5m

4.0°/s max.

2.0°/s max.

10.0°/s max.

Azimuth

Elevation

Polarisation

Dimensions

Main antenna case

Main segment case

Small segment case (1.5m only)

944 x 540 x 358mm

990 x 580 x 400mm

N/A

944 x 540 x 358mm

990 x 580 x 400mm

990 x 580 x 450mm

Weight

Sub 32kg configuration:

Main antenna case

Main segment case

Small segment case

32

32

N/A

31

31

30.5

Quick deployment configuration:

Main antenna case

Main segment case

Small segment case

41

23

N/A

44

31

17.5

Vehicle mounted configuration (no

cases or roof bars):

53 66

VISLINK

Flydrive 120-150 Antenna 9

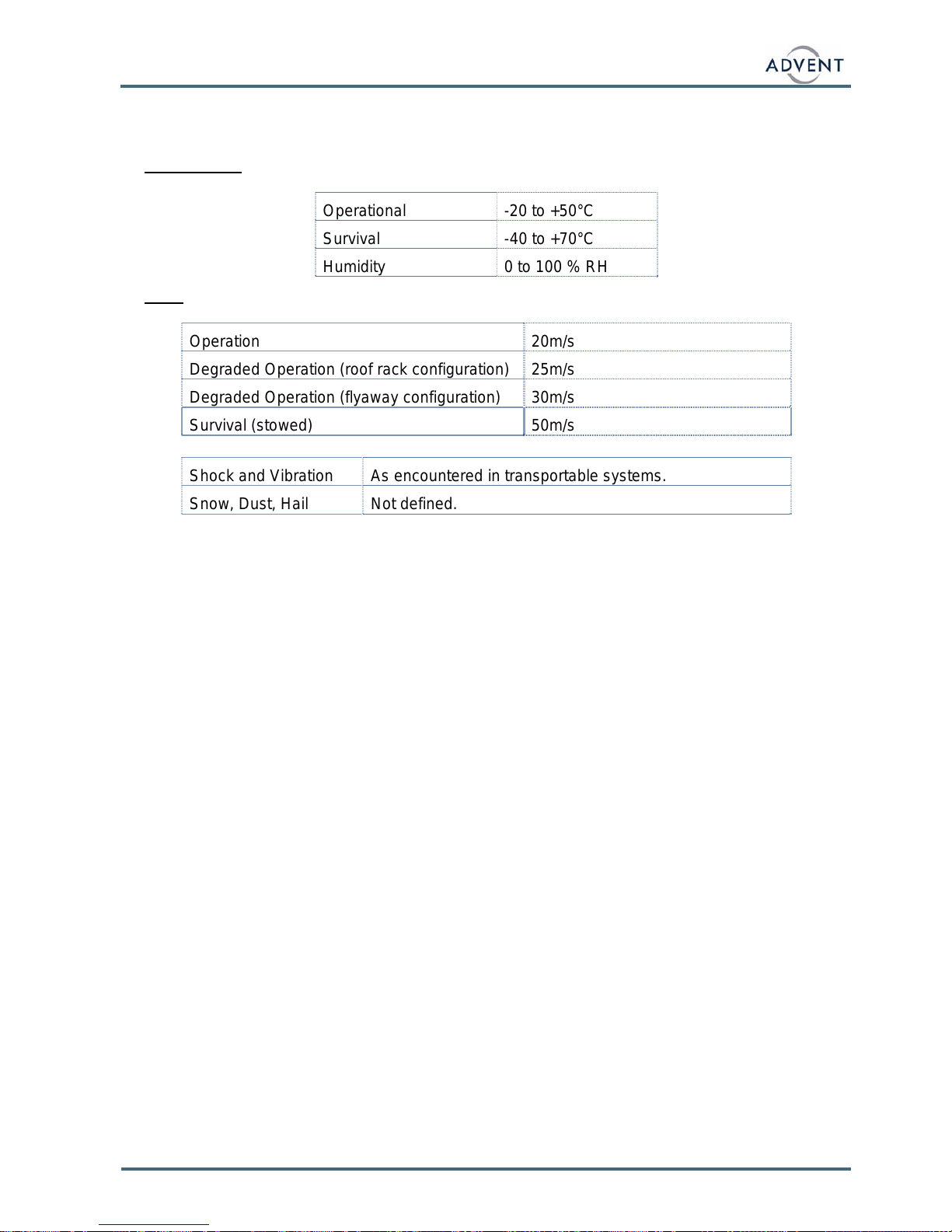

2.4 ENVIROMENTAL SPECIFICATION

The system will be used outdoors, exposed to the prevailing ambient conditions.

Temperature

Operational -20 to +50°C

Survival -40 to +70°C

Humidity 0 to 100 % RH

Wind

Operation 20m/s

Degraded Operation (roof rack configuration) 25m/s

Degraded Operation (flyaway configuration) 30m/s

Survival (stowed) 50m/s

Shock and Vibration As encountered in transportable systems.

Snow, Dust, Hail Not defined.

VISLINK

Flydrive 120-150 Antenna 10

3. OPERATING PROCEDURE

See Section 5 for the relevant assembly images.

3.1 ANTENNA ASSEMBLY – FLYAWAY CONFIGURATION

Open up the main antenna case.

If the antenna was stowed in its sub 32kg configuration (see section 3.4), remove the

four elevation arm fasteners from the main azimuth base. If the antenna was stowed in

its quick deployment configuration then go to the 6th bullet point. See section 3.4 for the

different case configurations.

Remove the reflector centre section from the segment case and place on top of the

azimuth base, in front of the azimuth cable interface. Connect up the cables from the

elevation axis to the azimuth cable interface panel (elevation motor cable, inclinometer

cable, elevation sensor cable, feedarm limit switch cable and the compass cable - when

supplied).

Place the reflector centre section onto the turntable using the dowels to aid location.

Care should be taken to make sure that the lower feedarm is released when locating the

reflector centre section. If necessary the lower feedarm can be released by gently

pushing up the two retaining clips on the side of the feedarm and lifting the feedarm.

Also ensure that the elevation sensor wire does not get trapped under the pivot leg.

Replace the four elevation axis bolts.

Place the main antenna case lid on the ground and place the main antenna base back

on top of the case.

Fasten the latches that secure the base onto its case.

Fit the front and rear antenna stabilising legs and adjust so that the antenna base is

level.

Connect the power and control cables to the main base cable interface panel.

Repetitively select the deploy command from the front panel of the ACU. On each deploy

command the elevation will raise up a few degrees then stop. Continue the deploy

commands until the elevation axis continues moving up at a higher rate once the

elevation stow sensor has been cleared.

Connect the upper feedarm to the lower feedarm.

Fasten the cartridge to the upper feedarm.

Fit the flex twist waveguide to the lower feedarm and cartridge RF ‘in’ port using the

quick release flange.

Place the flex twist waveguide over the waveguide support half way up the upper

feedarm.

Connect the polarisation motor control cable to the azimuth cable interface panel.

Connect the L band cable between the LNB and azimuth cable interface panel. Care

should be taken to pass both cables over the feedarm as shown. Use the Velcro straps

to hold the polarisation motor cable and L band cable to the flex twist waveguide and

other cables.

On the Flydrive 120, fit the three outer reflector segments, fitting the two side segments

first and the top segment last. On the Flydrive 150, fit the top centre section first, then

the lower outer sections, then the upper outer sections.

VISLINK

Flydrive 120-150 Antenna 11

Ensure that the polarisation drive is in its stowed position by looking at the polarisation

scale. If it is not in it’s stow position then rotate the feed to it’s stow position by pushing

the LNB to move the back section of the feedhorn. Select the stow command from the

front panel of the ACU. Once stowed, re-deploy the antenna and confirm that the

polarisation axis deploys and calibrates successfully.

The segment case may be used as a platform for any HPA or control electronics that are

being used with the system.

To stow the antenna remove the reflector segments, feedarm and cartridge, and select

the stow command from the front panel of the ACU. The antenna will stow with the

elevation axis stopping in its high stow position. If the elevation axis is required to be put

into its lower elevation stow position, to fit the unit in its flight case, selecting the stow

command from the front panel of the ACU will command the Flydrive to move to its lower

elevation stow position.

If the antenna is to be stowed in its sub 32kg configuration also removes the reflector

centre section. The two case configurations are shown in section 3.4.

VISLINK

Flydrive 120-150 Antenna 12

3.2 ANTENNA ASSEMBLY – ROOF RACK MOUNT CONFIGURATION

Warning:

The antenna should be fitted with the reflector facing the rear of the vehicle to

reduce wind loads during transit and protect the feedhorn assembly.

All fasteners and fitting that hold the antenna onto the vehicle and hold parts of

the antenna together should be checked before every journey. If any fasteners

are damaged then the vehicle should not be driven with the antenna fitted to

the roof rack. Try to push and pull the antenna out of its locked position. If any

movement is seen then the roof rack fittings should be tightened.

All checks associated with the roof rack should also be carried out.

If you are in any doubt that the antenna and all its parts are not securely held in

place then do not drive the vehicle with the antenna fitted to the roof rack.

The load capacity for the roof rack and vehicle should not be exceeded and

Advent recommends the use of higher load capacity roof rack components. For

example, a set of Thule 755 feet have a rated maximum load capacity of 100kg

compared to 75kg for standard feet. The increased load capacity will improve

the system stiffness and so reduce any RF losses.

Fit the roof rack (not supplied) to the vehicle if not already present. The roof rack bars

and feet and vehicle should be capable of supporting the antenna weight including any

amplifier and/or RF options. If there is an option for a high strength/stiffness rack, then

this should be fitted (for example, Thule supply reinforced load bars and higher load

capacity feet).

As with the flyaway configuration, fit the reflector centre section if the antenna was

stowed in its sub 32kg configuration.

Fit the antenna base front roof rack rails onto the main antenna base. The rear roof rack

rails are permanently fitted to the antenna base.

Slide the roof rack feet onto the rails and fit the end caps. Ensure that the end caps are

pushed fully into the roof bars. Use the end caps with the short extensions on the rear

bars and the end caps with the long extensions on the front bars.

Open up the roof bar feet sufficiently so that they may be slid over the roof rails on the

vehicle.

Lift the antenna base onto the roof rack bars and slide the roof rack feet so that they are

positioned at the correct width to fit the roof rack. Engage the roof rack feet over the roof

rack bars and tighten the roof rack feet and push the end cap fully in.

Partially deploy the antenna as with the flyaway configuration. Fit the lower and upper

feedarm and connect all cables and flex/twist waveguide. Fit the outer reflector

segments.

Note: - Consideration should be given to the vehicle suspension movement during

operation. Ideally jacks should be used to lock the vehicle suspension during operation

and may be necessary for operation at the higher end of the specified operational wind

speeds. If the vehicle does not have its suspension locked off and the wind loads do not

affect the antenna performance, movement due to people entering or leaving the vehicle

can be significant and may result in a temporary reduction in RF performance. Steps

should be taken to reduce the chance of this happening.

If the optional HPA mounting kit is supplied, fit the mounting brackets onto the HPA and

VISLINK

Flydrive 120-150 Antenna 13

lift the amplifier onto the roof rack next to the antenna base.

Fasten the inner HPA mounting bracket onto the main antenna base.

Fasten the outer clamp around the roof bar.

Fit the cross site waveguide between the HPA and feedarm base waveguide interface.

Care should be taken in operation that the flex/twist waveguide can run freely between

the amplifier and antenna. An antenna movement of between +90 and –180 degrees in

azimuth should not cause problems, but it may be necessary to either point the antenna

without the cross site waveguide fitted or move the vehicle for full 360 degrees azimuth

movement.

Select the deploy command from the front panel of the ACU. The Flydrive will deploy

automatically, calibrating the elevation, azimuth and polarisation axis on each deploy

sequence. Select the stow command from the front panel of the ACU. The Flydrive will

stow automatically.

To remove the roof rack feet from the antenna, remove the end cap completely from the

end cap housing and push the inner release latch in and pull the end cap housing out of

the roof bar.

3.3 MANUAL OPERATION

The antenna may be moved manually if there is a problem with the control circuit.

The azimuth axis is moved by inserting the manual drive a handle into the azimuth adjust

slot in the side of the antenna base and turning.

Apply power to the antenna using the main power cable. The elevation axis is moved by

releasing the brake using the switch on the main antenna cable interface panel and

inserting the manual drive handle into the elevation adjust slot in the side of the antenna

base and turning.

The polarisation axis is moved by rotating the rear section of the feedhorn.

If AC power is not available a 12V DC input may be used to release the brakes. Insert

the supplied brake override DC input cable, apply a 12V DC battery and use the brake

release switch as with the AC input. The cable pin outs are shown below.

VISLINK

Flydrive 120-150 Antenna 14

3.4 ANTENNA STOW CONFIGURATIONS

The antenna may be stowed in its cases in one of two configurations. The first configuration

keeps the cases below the 32kg IATA requirement for air travel, but requires more setup

time. The second quick deployment configuration allows the antenna to be assembled in less

time but results in one case that exceeds 32kg.

Flydrive 120 sub 32 kg configuration

Main antenna case contents:

Antenna base

Antenna stabilising legs and levelling feet

Upper feedarm

Reflector left section

Reflector right section

Segment case contents:

Reflector centre section (with lower feedarm and elevation axis attached)

Reflector top section

Accessory case contents:

Feedhorn cartridge

Roof rack runners and feet (when supplied)

Flydrive 120 quick deployment configuration

Main antenna case contents:

Antenna base

Reflector centre section (with lower feedarm and elevation axis attached)

Segment case contents:

Antenna stabilising legs and levelling feet

Upper feedarm

Feedhorn cartridge

Roof rack runners and feet (when supplied)

Reflector top section

Reflector left section

Reflector right section

VISLINK

Flydrive 120-150 Antenna 15

MAIN ANTENNA CASE FLYDRIVE 120

QUICK DEPLOYMENT

SUB 32Kg

SEGMENT CASE FLYDRIVE 120

QUICK DEPLOYMENT

SUB 32Kg

ACCESSORY CASE

VISLINK

Flydrive 120-150 Antenna 16

Flydrive 150 sub 32kg configuration

Main antenna case contents:

Antenna base

Upper feedarm

Feedhorn cartridge

Segment case contents:

Lower:- Reflector centre top section

Reflector left top section

Reflector right top section

Upper:- Reflector left bottom section

Reflector right bottom section

Feedarm flex/twist waveguide (1.3m)

Front roof bars

Thule feet with adjusters x 4

Antenna levelling feet and tool kit

Small segment case contents:

Lower:- Reflector centre section (with lower feedarm and elevation axis attached)

Antenna stabilising legs

Upper:- Cross site waveguide (1.1m)

AC power cable

Rx L band cable

Flydrive 150 quick deployment configuration

Main antenna case contents:

Antenna base

Reflector centre section (with lower feedarm and elevation axis attached)

Segment case contents (this is the same as the quick deploy configuration):

Lower:- Reflector centre top section

Reflector left top section

Reflector right top section

Upper:- Reflector left bottom section

Reflector right bottom section

Feedarm flex/twist waveguide (1.3m)

Front roof bars

Thule feet with adjusters x 4

Antenna levelling feet and tool kit

Small segment case contents:

Lower:- Antenna stabilising legs

This manual suits for next models

6

Table of contents

Other Vislink Antenna manuals

Popular Antenna manuals by other brands

True

True Jiuzhou JZDTS5418 How to set up

Taco

Taco Y102B-150V Instruction booklet

M2 Antenna Systems

M2 Antenna Systems 7-10-30LP8 Assembly instructions

Hirschmann

Hirschmann GLONASS 9 M Mounting instructions

Applied Satellite Engineering

Applied Satellite Engineering ASE AA511 quick start guide

Mopar

Mopar 82210940AD manual