4DE1805

3. Increase the range gradually, until detection is assured when

you walk straight towards the detector, across the detector's

field of view and diagonally within the protected area.

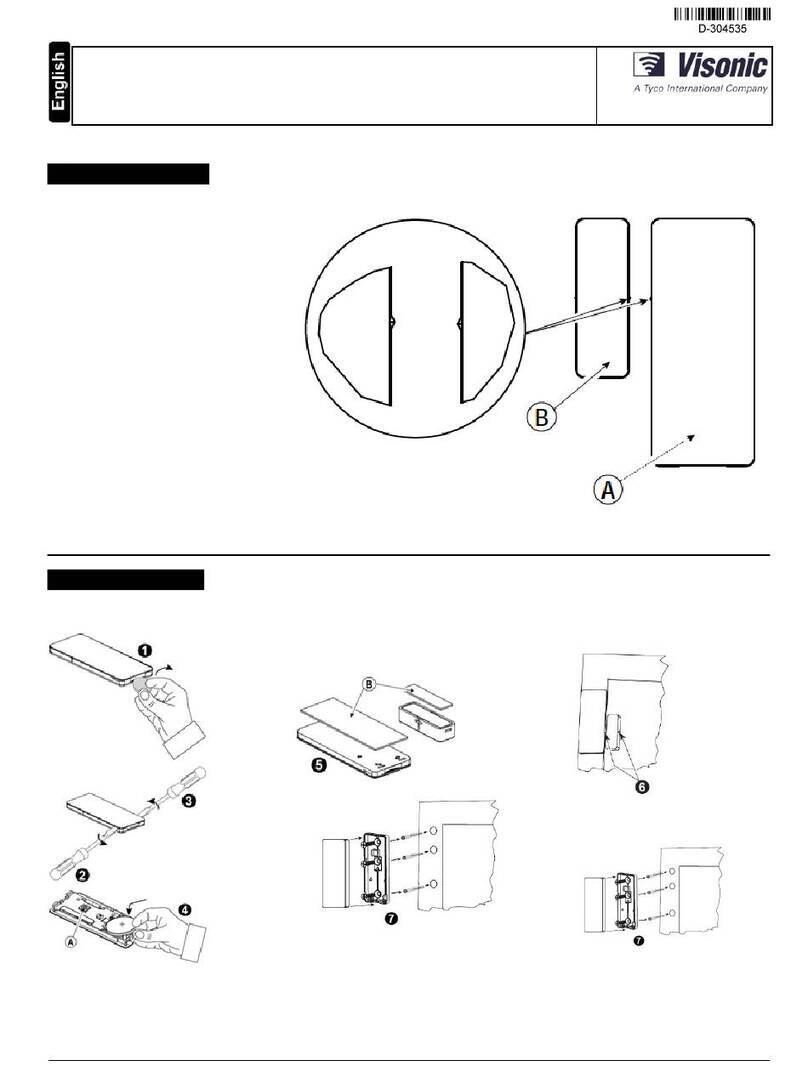

3.4 Changing the Lens

A. Remove the DUET's front cover.

B. Insert a screwdriver blade beneath one of the lens retainer's

flexible sides, lever the edge free of the restraining tabs and

remove the lens.

C. Insert the new lens with its smooth surface outside. Observe

its trapezoidal shape and fit the lens into place with the

longest side along the bottom of the cover (toward the 'creep

zone' lens).

Note: Since the lens retainer matches the shape of the lens,

position it correctly before performing the next step.

D. Insert one edge of the lens retainer below the restraining tabs

of the cover and force the other side inward with your fingers

until it snaps into place.

Coverage patterns for the interchangeable lenses are shown

in Section 2. Lens No. 15D is UL-approved.

3.5 Setting the Jumpers

Three jumper selectors control 3 different functions of the DUET

detector. Each jumper is set to ON by mounting it on the top and

middle pins, and set to OFF by mounting it on the bottom and

middle pins (Fig. 6). Before testing the DUET, set all 3 jumpers

according to your specific requirements.

PULSE – Pulse Count Selector

When this jumper is set to OFF, the PIR operates in the single-

pulse mode. When set to ON, the PIR operates in the 2-pulse

Alternate Polarity mode. (refer to Para. 3.2).

WALK – Alarm Indicator ON/OFF

When the WALK jumper is set to

ON, the walk-test indication of the

red LED is enabled. When the

switch is set to OFF, the walk test

indication is disabled. Figure 6. Jumper Selectors

DIAG – Diagnostic Indications ON/OFF

When the DIAG jumper is set to ON, the diagnostic indications of

the two technologies are enabled. The green LED indicates a PIR

trip and the yellow LED indicates a Microwave trip. When the

switch is set to OFF, the diagnostic indications are disabled.

3.6. Powering Up the Detector

Connect the system to its power source. Since the DUET

requires about 100 seconds to stabilize, the relay is maintained

energized throughout this period, and the red LED flashes

indicating that stabilization is in progress. Normal operation

begins after the 100-second delay.

3.7 General Testing Information

The DUET enables the installer and the user to check the dual

detector combined area coverage (Walk Test) as well as each

individual technology (Diagnostic Test).

The UL and other authorities require to switch off the walk test

and diagnostic indication after installing the alarm system, to

prevent potential intruders from discovering the precise detection

pattern of the detector. The WALK jumper, when set to OFF,

disables the Walk Test indication. The DIAG jumper, when set to

OFF, disables the Diagnostic indications.

3.8 Walk Test

When the PIR and Microwave technologies detect motion at the

same time, the relay is activated for 3 to 5 seconds and

simultaneously the RED LED indicates an alarm condition. This

enables the installer and the end-user to check the coverage

pattern of the detector and its proper function.

A. Set the WALK jumper to ON, to enable the Walk Test

indication (red LED).

B. Walk test the entire range and coverage area by walking

across the field of view of the detector. Observe the red LED.

It will light up whenever you are detected by both technologies.

Allow two seconds between each test for the unit to stabilize.

C. After completing the walk test, disable the red LED by setting

the WALK jumper to OFF.

Attention: The range and complete coverage area should

be checked at least once a year. To assure proper

continuous function, the user should be instructed to

perform a walk test at the far end of the coverage pattern to

assure an alarm signal prior to each time the alarm system

is armed.

3.9 Diagnostic Test

If required, you can walk-test each technology separately, using

the DIAGNOSTIC indication via the GREEN LED (PIR) and the

YELLOW LED (MW), to determine the exact detection areas of

the PIR and MW detectors. The results of such individual walk

tests are helpful in analyzing a detection or false alarm problem

and making corrections or adjustments accordingly.

A. Set the DIAG jumper to ON, to enable the diagnostic

indications (green and yellow LEDs).

B. Test the entire range and coverage area by walking across

the field of view of the detector in various directions. Observe

the yellow and green LEDs. Each will light for 3 to 5 seconds

whenever you are detected by the corresponding technology.

C. After completing the test, disable the diagnostic indications by

setting the DIAG jumper to OFF.

WARRANTY

WARRANTYWARRANTY

WARRANTY

Visonic Ltd. and/or its subsidiaries and its affiliates ("the Manufacturer") warrants its

products hereinafter referred to as "the Product" or "Products" to be in conformance with

its own plans and specifications and to be free of defects in materials and workmanship

under normal use and service for a period of twelve months from the date of shipment by

the Manufacturer. The Manufacturer's obligations shall be limited within the warranty

period, at its option, to repair or replace the product or any part thereof. The Manufacturer

shall not be responsible for dismantling and/or reinstallation charges. To exercise the

warranty the product must be returned to the Manufacturer freight prepaid and insured.

This warranty does not apply in the following cases: improper installation, misuse,

failure to follow installation and operating instructions, alteration, abuse, accident or

tampering, and repair by anyone other than the Manufacturer.

This warranty is exclusive and expressly in lieu of all other warranties, obligations or

liabilities, whether written, oral, express or implied, including any warranty of

merchantability or fitness for a particular purpose, or otherwise. In no case shall the

Manufacturer be liable to anyone for any consequential or incidental damages for breach

of this warranty or any other warranties whatsoever, as aforesaid.

This warranty shall not be modified, varied or extended, and the Manufacturer does not

authorize any person to act on its behalf in the modification, variation or extension of this

warranty. This warranty shall apply to the Product only. All products, accessories or

attachments of others used in conjunction with the Product, including batteries, shall be

covered solely by their own warranty, if any. The Manufacturer shall not be liable for any

damage or loss whatsoever, whether directly, indirectly, incidentally, consequentially or

otherwise, caused by the malfunction of the Product due to products, accessories, or

attachments of others, including batteries, used in conjunction with the Products.

The Manufacturer does not represent that its Product may not be compromised and/or

circumvented, or that the Product will prevent any death, personal and/or bodily injury

and/or damage to property resulting from burglary, robbery, fire or otherwise, or that the

Product will in all cases provide adequate warning or protection. User understands that a

properly installed and maintained alarm may only reduce the risk of events such as

burglary, robbery, and fire without warning, but it is not insurance or a guarantee that such

will not occur or that there will be no death, personal damage and/or damage to property

as a result.

The Manufacturer shall have no liability for any death, personal and/or bodily injury

and/or damage to property or other loss whether direct, indirect, incidental,

consequential or otherwise, based on a claim that the Product failed to function.

However, if the Manufacturer is held liable, whether directly or indirectly, for any loss or

damage arising under this limited warranty or otherwise, regardless of cause or origin, the

Manufacturer's maximum liability shall not in any case exceed the purchase price of the

Product, which shall be fixed as liquidated damages and not as a penalty, and shall be the

complete and exclusive remedy against the Manufacturer.

Warning: The user should follow the installation and operation instructions and among

other things test the Product and the whole system at least once a week. For various

reasons, including, but not limited to, changes in environmental conditions, electric or

electronic disruptions and tampering, the Product may not perform as expected. The user

is advised to take all necessary precautions for his/her safety and the protection of his/her

property.

6/91

VISONIC LTD. (ISRAEL): P.O.B 22020 TEL-AVIV 61220 ISRAEL. PHONE: (972-3) 645-6789, FAX: (972-3) 645-6788

VISONIC INC. (U.S.A.): 10 NORTHWOOD DRIVE, BLOOMFIELD CT. 06002-1911. PHONE: (860) 243-0833, (800) 223-0020 FAX: (860) 242-8094

VISONIC LTD. (UK): UNIT 1, STRATTON PARK, DUNTON LANE, BIGGLESWADE, BEDS. SG18 8QS. PHONE: (01767) 600857 FAX: (01767) 601098

VISONIC LTD. 1998 DUET/UL D-1805-0 NEW: DE1805- (REV. 2, 4/98)