7

7

General Information

Information – read carefully

Read and understand this manual before using this Product. The

manual must be available in the national language at all times. If

not available, then the vendor has to resolve this matter with

SKYLOTEC prior to sale. The instructions must be made available

to the user. The equipment may only be used by professional

users, who have received training in its safe usage and who

possess the required knowledge. A rescue plan must be available

for any eventuality. It must be possible to implement rescue

measures in a timely manner.

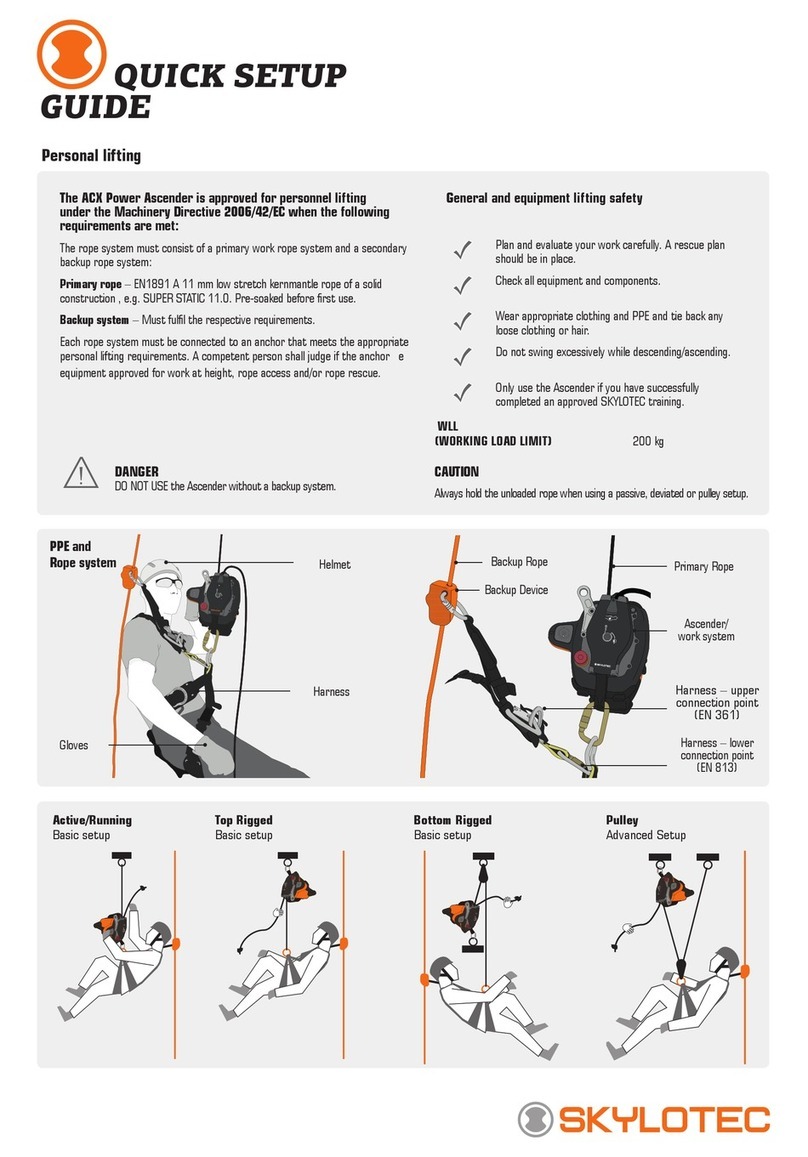

Rescue system

A rescue system consists of the illustrated individual components

and may only be used with tested and approved components under

the described application conditions; failure to comply represents a

risk of serious or fatal injury. Anchoring points should be selected/

positioned directly above the victim, if possible.The anchor point

must meet the requirements of EN 795 for the scope of application.

Also, the substructure to which the anchoring device is fastened,

and the connecting elements have to be able to withstand the load.

Prior to use

Check the complete personal protective equipment (PPE) and its

individual components for damage, cracks or wear (including

snaphooks, straps, textile and metal components, adjusting

devices, locks); complete function must be assured. If unsure the

component is in a safe condition, remove immediately.

The equipment must be immediately removed from service after a

fall and checked by an expert. If it can no longer be used, it must be

disposed.

Safety requirements

The instructions on protecting the user and the equipment must be

strictly complied with! The product label must be completely legible!

In order to avoid a suspension trauma in case of a fall, there must

be an rescue plan available that is designed to reduce the amount

of time suspended while wearing a harness, and consequently to

prevent a circulatory collapse. It is an important requirement for the

user to check all attachment and/or adjustment parts regularly

during use.

• Application temperature -35 to +40 °C

• Store dry and protected from light and transport correctly

• Avoid contact with corrosive substances

• Consider danger of suspension trauma

• Avoid edge loading and watch out for abrasive surfaces.

• Consider danger from electrical equipment

• Consider danger by moving machine parts

• Do not put on personal protective equipment in the location

where there is a risk of falling.