4 D-300767

6. SYSTEM FUNCTIONAL TEST

6.1 Valve(s) Manual Closing/Opening Test

A. Valve(s) Manual Closing Test

1. Press the CLOSE button (see figure 6).

2. Verify that the water valve(s) will be closed within few seconds, during

which the red CLOSED LED (see figure 1) will flash. At the end of the

closing process, the red CLOSED LED will constantly light and the

valve(s) status indicator (see figure 8) should indicate "closed".

B. Valve(s) Manual Opening Test

1. Press the OPEN button (see Fig. 6).

2. Verify that the water valve(s) will be open within few seconds, during

which the red CLOSED LED (see figure 1) will flash. At the end of the

opening process, the red CLOSED LED will not light and the valve(s)

status indicator (see figure 8) should indicate "open".

6.2 Valve(s) Automatic Closing Test

1. Thoroughly clean the flood detectors' sensors (see figure 1) with a rag

and Immerse them in water (for example, by using a glass of water) and

verify that the water valve(s) will be closed within few seconds. During the

closing process, the red CLOSED LED (see Fig. 1) will flash.

At the end of the closing process, the red CLOSED LED will light

steadily and the valve(s) status indicator (see Fig. 8) should indicate

"closed".

2. Press the OPEN button (see Fig. 6), and verify that the water supply is

restored.

3. Perform steps 1 and 2 for every system's flood sensor.

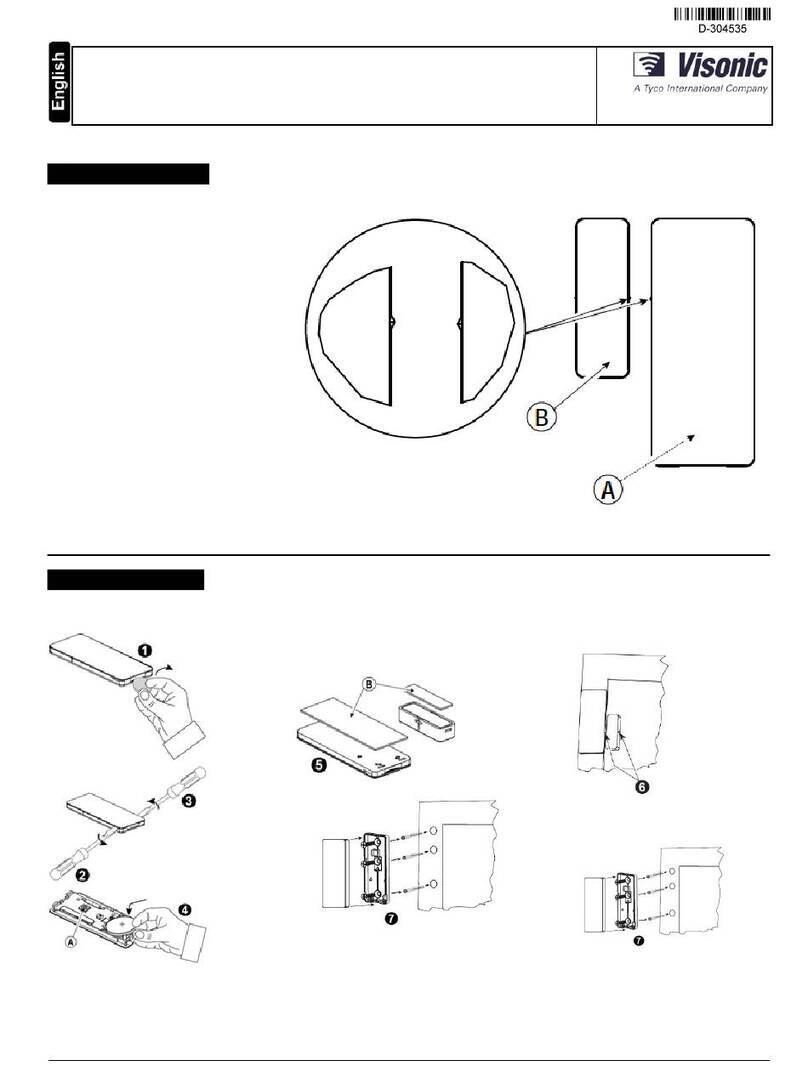

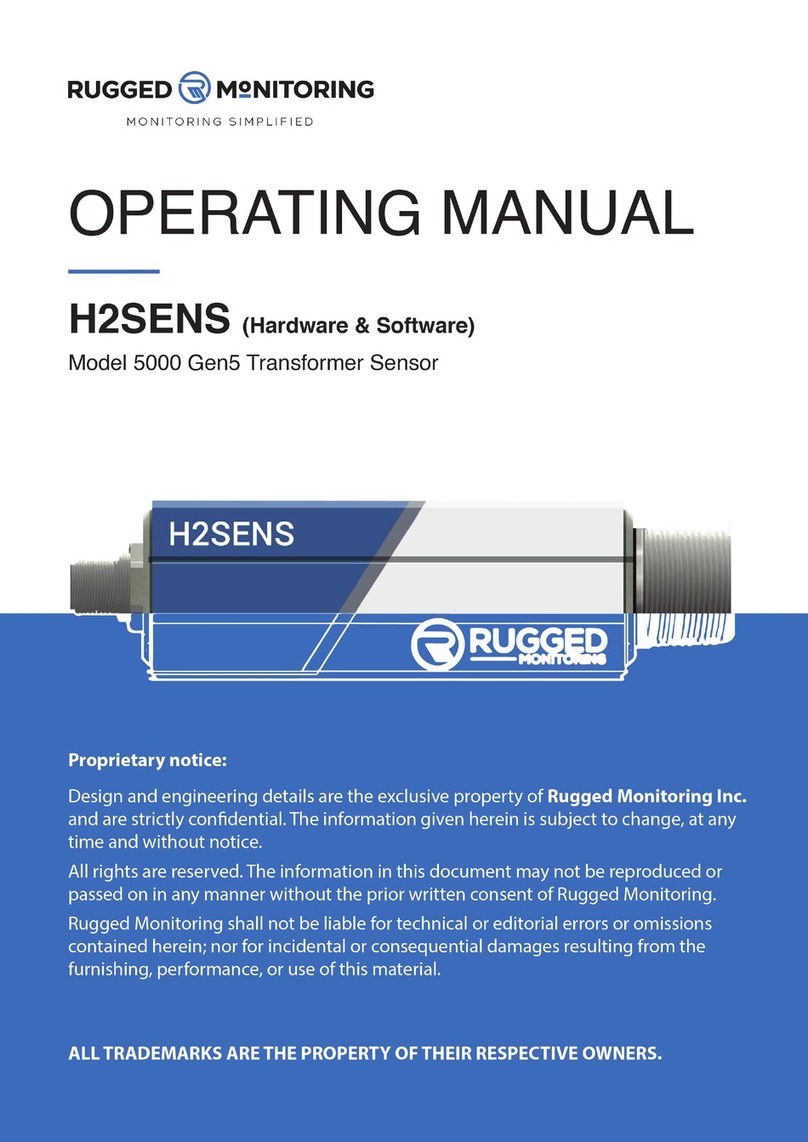

Figure 8 - Water Valve Status Indication

7. MAINTENANCE

System functional test must be performed every 3 months at least,

including thorough cleaning of the flood sensors, according to section 6. After the test turn the valve(s) to OPEN position (see par. 6.2.B).

8. SPECIAL NOTES

Although this system is a highly reliable system, it does not guarantee complete

protection against flood. Even the most sophisticated systems can sometimes

be defeated or may fail because of:

A. Incorrect or improperly connected power supply.

B. The ambient temperature of the protected site is outside the range

specified in the SPECIFICATION section.

C. Even the most reliable electrical systems, including this system, may go

wrong because of an unexpected failure of a component part and may

cause closing or opening of the water valve(s).

D. When the electric power fails, it is impossible to close/open the water

valve(s).

A protection system should not be regarded as a substitute for insurance.

Home and property owners or renters should be prudent enough to continue

insuring their lives and property, even though they are protected by the flood

protection system.

Due to low transmitting power and limited range (required by FCC and other

regulatory authorities), there are some limitations to be considered:

A. Receivers may be blocked by radio signals occurring on or near their

operating frequencies.

B. Wireless equipment should be tested regularly to determine whether there are

sources of interference and to protect against faults.

The user is cautioned that changes or modifications to the unit, not

expressly approved by Visonic Ltd., could void the user's FCC authority

to operate the equipment.

This device has been designed to comply with the European Council Directive

EMC 89/336/EEC & 92/31/EEC and bears the CE mark and certification.

This device has been designed to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in residential

installations. This equipment generates uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may

cause harmful interference to radio and television reception. However, there is

no guarantee that interference will not occur in a particular installation. If this

device does cause such interference, which can be verified by turning the

device off and on, the user is encouraged to eliminate the interference by one

or more of the following measures:

– Re-orient or re-locate the receiving antenna.

– Increase the distance between the device and the receiver.

– Connect the device to an outlet on a circuit different from the one which

supplies power to the receiver.

– Consult the dealer or an experienced radio/TV technician.

WARRANTY

Visonic Limited (the “Manufacturer") warrants this product only (the "Product") to the original

purchaser only (the “Purchaser”) against defective workmanship and materials under normal use of

the Product for a period of twelve (12) months from the date of shipment by the Manufacturer.

This Warranty is absolutely conditional upon the Product having been properly installed, maintained

and operated under conditions of normal use in accordance with the Manufacturers recommended

installation and operation instructions. Products which have become defective for any other reason,

according to the Manufacturers discretion, such as improper installation, failure to follow

recommended installation and operational instructions, neglect, willful damage, misuse or vandalism,

accidental damage, alteration or tampering, or repair by anyone other than the manufacturer, are not

covered by this Warranty.

The Manufacturer does not represent that this Product may not be compromised and/or

circumvented or that the Product will prevent any death and/or personal injury and/or damage to

property resulting from burglary, robbery, fire or otherwise, or that the Product will in all cases

provide adequate warning or protection. The Product, properly installed and maintained, only

reduces the risk of such events without warning and it is not a guarantee or insurance that such

events will not occur.

THIS WARRANTY IS EXCLUSIVE AND EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES,

OBLIGATIONS OR LIABILITIES, WHETHER WRITTEN, ORAL, EXPRESS OR IMPLIED,

INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE, OR OTHERWISE. IN NO CASE SHALL THE MANUFACTURER BE LIABLE TO

ANYONE FOR ANY CONSEQUENTIAL OR INCIDENTAL DAMAGES FOR BREACH OF THIS

WARRANTY OR ANY OTHER WARRANTIES WHATSOEVER, AS AFORESAID.

THE MANUFACTURER SHALL IN NO EVENT BE LIABLE FOR ANY SPECIAL, INDIRECT,

INCIDENTAL, CONSEQUENTIAL OR PUNITIVE DAMAGES OR FOR LOSS, DAMAGE, OR

EXPENSE, INCLUDING LOSS OF USE, PROFITS, REVENUE, OR GOODWILL, DIRECTLY OR

INDIRECTLY ARISING FROM PURCHASER’S USE OR INABILITY TO USE THE PRODUCT, OR

FOR LOSS OR DESTRUCTION OF OTHER PROPERTY OR FROM ANY OTHER CAUSE, EVEN

IF MANUFACTURER HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGE.

THE MANUFACTURER SHALL HAVE NO LIABILITY FOR ANY DEATH, PERSONAL AND/OR

BODILY INJURY AND/OR DAMAGE TO PROPERTY OR OTHER LOSS WHETHER DIRECT,

INDIRECT, INCIDENTAL, CONSEQUENTIAL OR OTHERWISE, BASED ON A CLAIM THAT THE

PRODUCT FAILED TO FUNCTION.

However, if the Manufacturer is held liable, whether directly or indirectly, for any loss or damage

arising under this limited warranty, the Manufacturer's maximum liability (if any) shall not in any case

exceed the purchase price of the Product, which shall be fixed as liquidated damages and not as a

penalty, and shall be the complete and exclusive remedy against the Manufacturer.

When accepting the delivery of the Product, the Purchaser agrees to the said conditions of sale and

warranty and he recognizes having been informed of.

Some jurisdictions do not allow the exclusion or limitation of incidental or consequential damages, so

these limitations may not apply under certain circumstances.

The Manufacturer shall be under no liability whatsoever arising out of the corruption and/or

malfunctioning of any telecommunication or electronic equipment or any programs.

The Manufacturers obligations under this Warranty are limited solely to repair and/or replace at the

Manufacturer’s discretion any Product or part thereof that may prove defective. Any repair and/or

replacement shall not extend the original Warranty period. The Manufacturer shall not be

responsible for dismantling and/or reinstallation costs. To exercise this Warranty the Product must

be returned to the Manufacturer freight pre-paid and insured. All freight and insurance costs are the

responsibility of the Purchaser and are not included in this Warranty.

This warranty shall not be modified, varied or extended, and the Manufacturer does not authorize

any person to act on its behalf in the modification, variation or extension of this warranty. This

warranty shall apply to the Product only. All products, accessories or attachments of others used in

conjunction with the Product, including batteries, shall be covered solely by their own warranty, if

any. The Manufacturer shall not be liable for any damage or loss whatsoever, whether directly,

indirectly, incidentally, consequentially or otherwise, caused by the malfunction of the Product due to

products, accessories, or attachments of others, including batteries, used in conjunction with the

Products. This Warranty is exclusive to the original Purchaser and is not assignable.

This Warranty is in addition to and does not affect your legal rights. Any provision in this warranty

which is contrary to the Law in the state or country were the Product is supplied shall not apply.

Warning: The user must follow the Manufacturer’s installation and operational instructions including

testing the Product and its whole system at least once a week and to take all necessary precautions

for his/her safety and the protection of his/her property. 1/08

W.E.E.E. Product Recycling Declaration

For information regarding the recycling of this product you must contact the company from which you orignially purchased it. If you are discarding this product and not

returning it for repair then you must ensure that it is returned as identified by your supplier. This product is not to be thrown away with everyday waste.

Directive 2002/96/EC Waste Electrical and Electronic Equipment.

VISONIC LTD. (ISRAEL): P.O.B 22020 TEL-AVIV 61220 ISRAEL. PHONE: (972-3) 645-6789, FAX: (972-3) 645-6788

VISONIC INC. (U.S.A.): 65 WEST DUDLEY TOWN ROAD, BLOOMFIELD CT. 06002-1376. PHONE: (860) 243-0833, (800) 223-0020. FAX: (860) 242-8094

VISONIC LTD. (UK): 7 COPPERHOUSE COURT, CALDECOTTE, MILTON KEYNES. MK7 8NL. PHONE: (0870) 7300800 FAX: (0870) 7300801

PRODUCT SUPPORT ( 0870) 7300830

INTERNET: www.visonic.com

©VISONIC LTD. 2008 MCW-570 Installation Instructions D-300767 (REV. 4, 11/08)

Open

Optional knob

Pull out and

rotate for

manual open /

close

Closed