VISTEK V1623 Owner's manual

01/03/2005 V1623_2OM.DOC Page 1 of 15

V1623

V1623K

Video Analogue to Digital Converter

Module

Key Channel Analogue to Digital

Converter Module

INSTALLATION and OPERATION

© Vistek Electronics Ltd

Filename: V1623om.doc

Issue : 2

Date: June 2002

VISTEK Electronics Ltd

Wessex Rd

Bourne End

Buckinghamshire, SL8 5DT

ENGLAND

Tel. +44 1628 531221

Fax. +44 1628 530980

Web: www.vistek.tv

01/03/2005 V1623_2OM.DOC Page 2 of 15

01/03/2005 V1623_2OM.DOC Page 3 of 15

Video Analogue to Digital Converter Module

INSTALLATION AND OPERATION

1. DESCRIPTION

This manual covers both the V1623 video analogue to digital converter and the V1623K Key Channel

analogue to digital converter. The Key Channel module has reduced functionality from the other version,

as unnecessary controls and components have been removed. The V1623K uses the Y/G channel of

the unit for the Key signal and the Pb/B and Pr/R channels are fixed at black in the processing.

The V1623 is a video analogue to digital converter, which forms part of the Vistek V1600 range of

interface products. It is a 3U high card, which is fitted into either a V1601, V1603 or V1606 rack from

which it gets its power and control. A passive rear module, 16VR1H or 16VR3H, is required for all

signal interconnections.

The unit is fully dual standard for both 625/50 and 525/60 D1 signals. It can automatically detect the

input standard and operate accordingly, or it can also be forced into a standard regardless of the input.

The unit can handle the analogue component signals in various formats to produce the standard D1

digital output. The formats are: -

Y, Pb, Pr (standard levels, Beta levels or US MII levels), with or without set-up

GBR with or without set-up

The sync reference may be a separate signal 300mV – 4V, or extracted from the Y or G signals.

Levels and timing parameters can be adjusted, along with blanking controls. An internal test pattern

generator is also included for alignment purposes.

Video Gain + 6dB

Chroma Gain + 6dB

Black Level + 100mV

Green Gain + 6dB (GBR Mode only)

Blue Gain + 6dB (GBR Mode only)

Red Gain + 6dB (GBR Mode only)

Input Format Y/Pb/Pr, GBR, MII, Beta

Output Standard 525, 625

Reference select Y/G, External

Reference Fail Mode Free Run, Black, Mute

Test Pattern Bars, Black, Picture Edge, Ramp, Split screen

Monochrome mode Colour, Monochrome

Picture position + 2.3 us

Y/C Timing + 0.55 us

Output Delay 0 – ½ line

Vertical Blanking

Wide Screen Blanking 4:3, 14:9, 16:9, Key Level

Error Detection & Handling On, Off

Limiting Set-up ear removal (525 modes only)

Engineering Mode Enables extra test Patterns & Mono Modes

Alignment mode Module alignment set-up modes

In common with all Vistek V1600 modular units there is a local control panel, which lets the user adjust

most of the controls. In addition the module may be controlled remotely using the DART system. DART

is the general purpose control architecture supplied by Vistek and other manufacturers, and enables full

control and monitoring of this and all other V1600 units.

01/03/2005 V1623_2OM.DOC Page 4 of 15

01/03/2005 V1623_2OM.DOC Page 5 of 15

2. INSTALLATION

2.1 REAR PANEL CONNECTIONS

The V1623 rear module connections are shown below.

3U Rear Module (16VR3H)1U Rear Module (16VR1H)

O/P

A2

O/P

A3

O/P

A4

Sync

(loop)

I/P

Y/G

I/P

Pb/B

I/P

Sync

I/P

Pr/R

DART

O/P

A1

O/P

A1

O/P

A2

O/P

A3

O/P

A4

I/P

Y/G

I/P

Pb/B

I/P

Pr/R

I/P

Sync

Sync

(loop)

* The V1623K Module has the Y/G input labeled as Key and the Pb/B and

Pr/R inputs are not connected.

2.2 INTERFACING

SIGNAL COMMENTS

Power 7.5W Supplied from rack

Analogue

Inputs BNC Video ( 700mV nominal, but will handle 1.4V signals)

Sync Reference (300mV – 4V) (looping un-terminated)

SDI O/P 1,2,3,4 BNC Video to SMPTE 259M. Drive cable length up to 200m

2.3 INSERTION DELAY

Sync Reference to SDI Output 6.3µs

01/03/2005 V1623_2OM.DOC Page 6 of 15

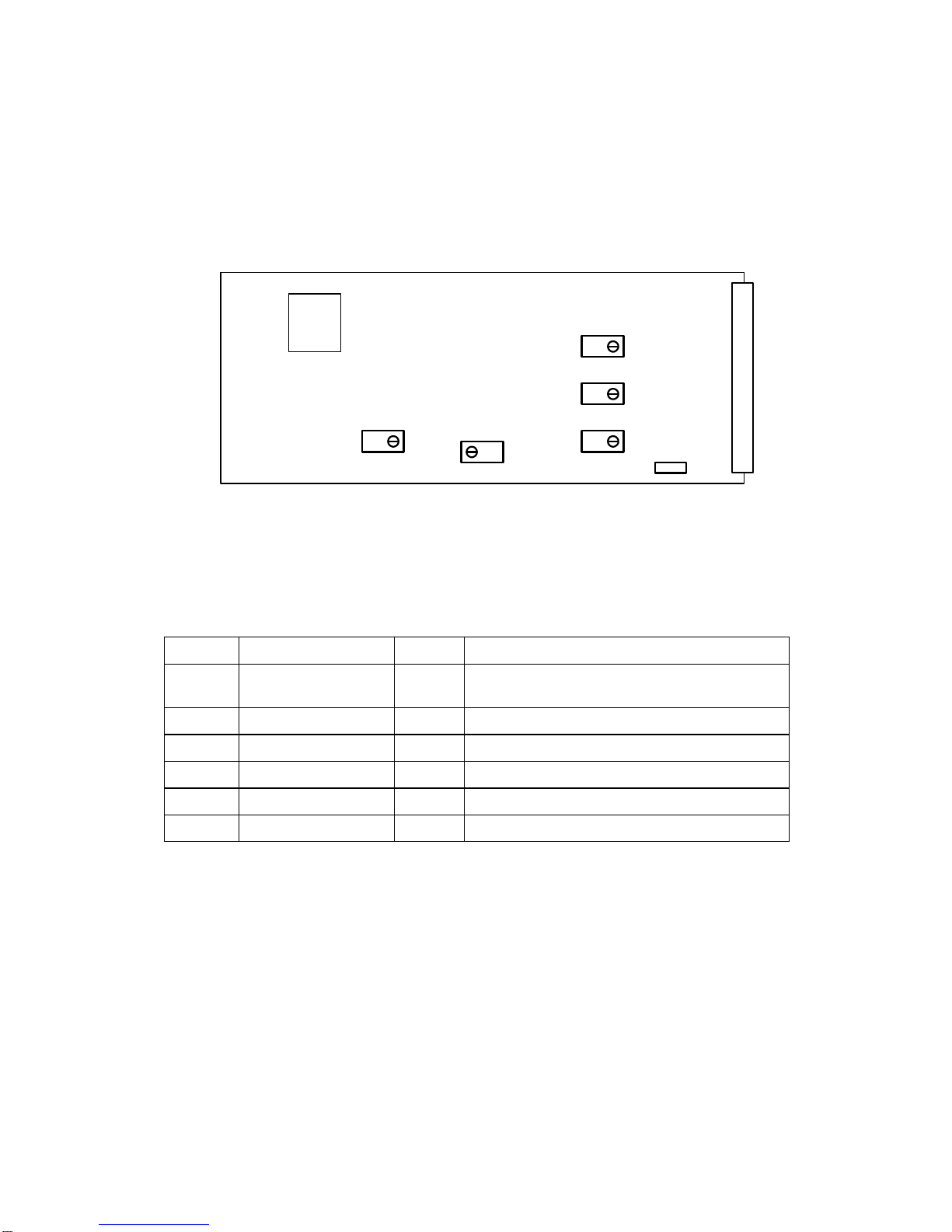

2.4 HARDWARE

The figure below shows diagrammatically the printed circuit board along with certain other components

of interest. In particular it shows the position and orientation of the controls and switches, which set up

the calibrated levels and External Reference level range.

The EPROM location is shown, as it is the component that would need to be changed as a result of any

software upgrade in the field.

Front Panel

Rear Connector

EPROM

SW5

VR1

VR2

VR3VR4 VR5

The purposes of the controls and switches are shown in the following table. Details of their operation

are described in later sections.

ITEM Title Section Comments

SW5 External Reference

input range Sets the reference input voltage range between

300mV - 1V and 1V - 4V

VR1 Y/G amplitude Calibrates the input analogue circuit

VR2 Pb/B amplitude Calibrates the input analogue circuit

VR3 Pr/R amplitude Calibrates the input analogue circuit

VR4 27MHz frequency Sets the freerun frequency of the oscillator

VR5 Fine phase Sets the clock edge to reference timing

01/03/2005 V1623_2OM.DOC Page 7 of 15

2.5 FRONT PANEL

REM +V

Local

Rem

V1623

Video

ADC

+-

DART Control Access and Power indicators

Local Control Page Selected

Local Control Parameter Selected

UP Button

Mode and Value LEDs (see below)

DOWN Button

REMOTE / LOCAL control selection

525 625 SDI Format Indicator

Ref

Local Control Selection

Select

V Gain A

C Gain B

G Gain C

B Gain D

R Gain E

Black F

321

The front panel shown above has three purposes:

Provide the user with the operating conditions

Offer Local control and indication of the primary controls

Select the control source

2.5.1 Operating Conditions

The LEDs at the top of the panel have these meanings

REM Short blinks to indicate access by the DART controller, if fitted. It does not

indicate that the unit is in one of its remote control modes.

+V Indicates that 5V is present on the board. This is derived from the +15V

distributed through the rack.

525 Indicates that a 525/60 format signal is being Output.

Green = Input. Amber = Test Pattern

625 Indicates that a 625/50 format signal is being Output.

Green = Input. Amber = Test Pattern

Ref Indicates that a valid Reference signal is being received.

Green = Locked Amber = Standard conflict Red = Failed

01/03/2005 V1623_2OM.DOC Page 8 of 15

2.5.2 Adjustments

The central section is used in Local control to select which of the four available pages and which of upto

6 available menus is to be adjusted and to make the adjustment. In remote mode or Page 0, menu 0,

the menu LEDs indicate by flashing if any of the gains are off their calibrated settings.

Selecting a page is done by holding down the select button and pressing the τbutton. The pages will

rotate around 0 – 1 – 2 – 3 – 4 – 0 etc.

Selecting a menu is done by pressing and releasing the select button. The menus will rotate A – B – C –

D – E – F – null – A etc. (Not all menus are available on each page, so non-available menus will be

skipped. Availability can also depend on operating modes.)

Once a control has been selected then it is changed by pressing the σand τbuttons.

Level and timing adjustments have rate laws on the σand τbuttons, so holding them down will increase

the speed of adjustment. Parameter adjustments are done in single steps, requiring button press and

release to step between them.

Any adjustment can be returned to its calibrated value by pressing the σand τbuttons simultaneously

for at least five seconds.

The three central LEDs give an indication of the parameter status. The exact meaning of each LED is

described in the following table. These LEDs will flash Amber on Page 0, menu 0 if the unit is left in

Engineering mode or Red if it is in Alignment mode.

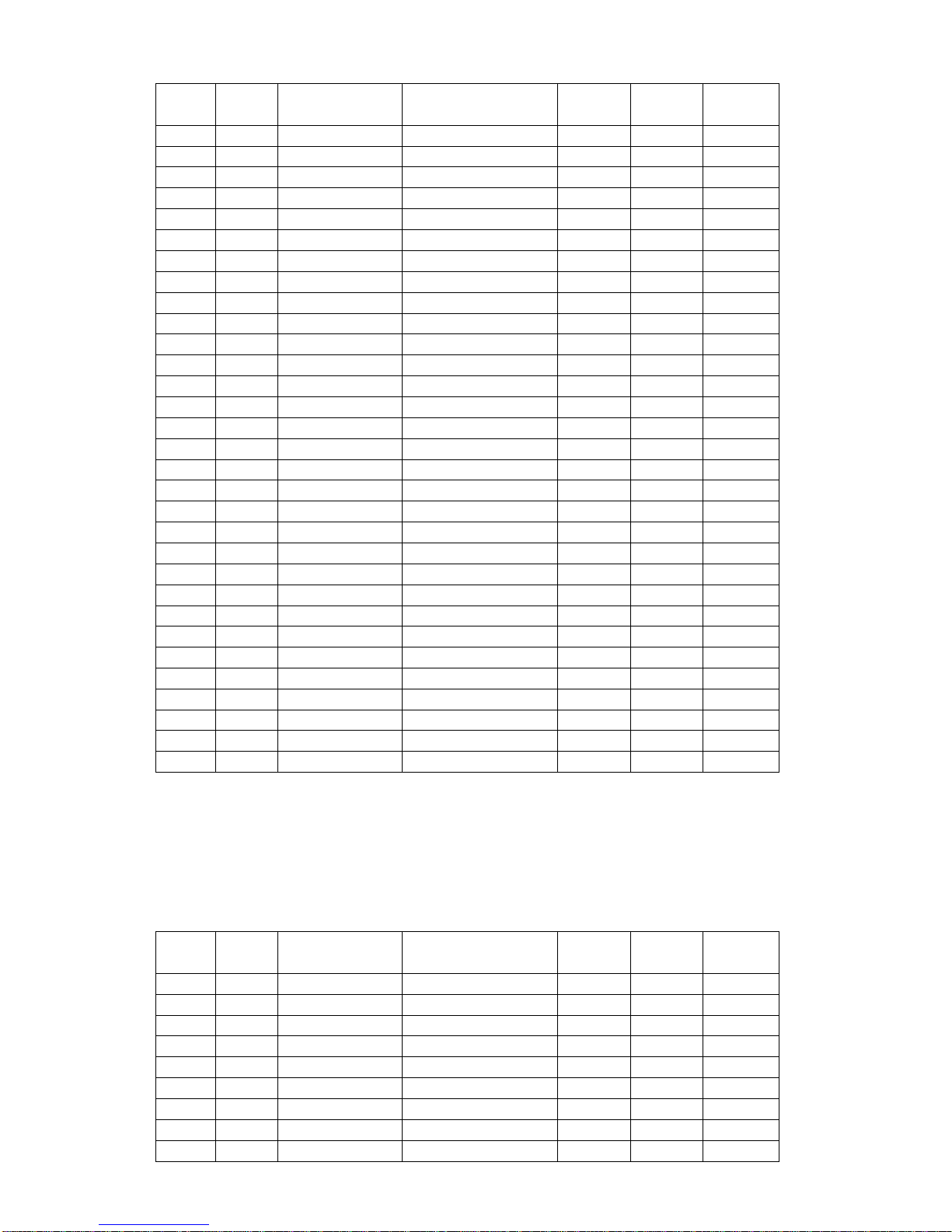

V 1623 Menu’s.

Page Menu Item Parameter /

Value ‘-‘ led ‘ ‘ led ‘+’ led

0 A Video Gain Calibrated Off Green Off

+ve gain Off Off Yellow

-ve gain Yellow Off Off

0 B Chroma Gain Calibrated Off Green Off

+ve gain Off Off Yellow

-ve gain Yellow Off Off

0 C *Green Gain Calibrated Off Green Off

(RGB Mode +ve gain Off Off Yellow

only) -ve gain Yellow Off Off

0 D *Blue Gain Calibrated Off Green Off

(RGB Mode +ve gain Off Off Yellow

only) -ve gain Yellow Off Off

0 E *Red Gain Calibrated Off Green Off

(RGB Mode +ve gain Off Off Yellow

only) -ve gain Yellow Off Off

0 F Black Level Calibrated Off Green Off

+ve gain Off Off Yellow

01/03/2005 V1623_2OM.DOC Page 9 of 15

-ve gain Yellow Off Off

01/03/2005 V1623_2OM.DOC Page 10 of 15

Page Menu Item Parameter /

Value ‘-‘ led ‘ ‘ led ‘+’ led

1 A I/P Standard YUV Off Off Off

RGB Off Off Green

RGB + Set-up Yellow Off Green

MII + Set-up Yellow Green Off

Beta + Set-up Yellow Green Green

Beta Off Green Green

1 B O/P Standard Last Used Off Off Off

Default 525 Green Off Off

Default 625 Off Green Off

Forced 525 Yellow Off Off

Forced 625 Off Yellow Off

1 C Reference I/P External Off Off Off

Y/G Off Off Green

1 D Ref Fail Free run Off Green Off

Mode O/P Black Off Yellow Off

O/P Mute Off Red Off

1 E Test Patterns Off Off Off Off

Colour Bars Off Off Yellow

Split Bars Yellow Off Yellow

Black Off Yellow Off

1 F Mono Mode Colour Green Green Green

Mono Green Off Off

2 A Picture Calibrated Off Green Off

Position Sync’s late Off Off Yellow

(wrt picture) Sync’s early Yellow Off Off

2 B *Y/C Timing Calibrated Off Green Off

(YUV Mode Chroma late Off Off Yellow

Only) Chroma early Yellow Off Off

2 C O/P Delay Minimum Off Green Off

Delay Off Off Off

2 D Vertical Normal Off Green Off

Blanking Narrow Yellow Off Off

2 E Widescreen Off Off Off Off

Blanking 14:9 Off Off Green

16:9 Off Green Off

14:9 + Key Yellow Off Green

16:9 + Key Yellow Green Off

01/03/2005 V1623_2OM.DOC Page 11 of 15

Page Menu Item Parameter /

Value ‘-‘ led ‘ ‘ led ‘+’ led

2 F EDH On Off Green Off

Off Off Off Off

3 A Limiting Off Off Off Off

Set-up ear limit Off Yellow Off

3 B Operating Normal Off Off Off

Mode Engineering Yellow Yellow Yellow

Alignment Red Red Red

3 C Test Off Off Off Off

Patterns Colour Bars Off Off Yellow

Split Bars Yellow Off Yellow

Black Off Yellow Off

(* Eng. Mode Edge of picture Off Off Red

Only) Split Edge Yellow Off Red

SDI Ramp Off Red Off

Split Ramp Yellow Red Off

3 D Mono Modes Colour Green Green Green

Y Only Green Off Off

(* Eng. Mode U Only Off Green Off

Only) V Only Off Off Green

**1 **A **Alignment Y to Y O/P only Off Off Off

B to Y O/P only Off Off Green

R to Y O/P only Yellow Off Green

Y/Pb to Y/Pb O/P Yellow Green Off

Y/Pr to Y/Pr O/P Off Green Off

Normal Off Green Green

V1623K Menu’s.

Page Menu Item Parameter /

Value ‘-‘ led ‘ ‘ led ‘+’ led

0 A Video Gain Calibrated Off Green Off

+ve gain Off Off Yellow

-ve gain Yellow Off Off

0 F Black Level Calibrated Off Green Off

+ve gain Off Off Yellow

-ve gain Yellow Off Off

01/03/2005 V1623_2OM.DOC Page 12 of 15

Page Menu Item Parameter /

Value ‘-‘ led ‘ ‘ led ‘+’ led

1 B O/P Standard Last Used Off Off Off

Default 525 Green Off Off

Default 625 Off Green Off

Forced 525 Yellow Off Off

Forced 625 Off Yellow Off

1 C Reference I/P External Off Off Off

Y Off Off Green

1 D Ref Fail Free run Off Green Off

Mode O/P Black Off Yellow Off

O/P Mute Off Red Off

1 E Test Patterns Off Off Off Off

Staircase Off Off Yellow

Split Staircase Yellow Off Yellow

Black Off Yellow Off

2 A Picture Calibrated Off Green Off

Position Sync’s late Off Off Yellow

(wrt picture) Sync’s early Yellow Off Off

2 C O/P Delay Minimum Off Green Off

Delay Off Off Off

2 D Vertical Normal Off Green Off

Blanking Narrow Yellow Off Off

2 E Widescreen Off Off Off Off

Blanking 14:9 Off Off Green

16:9 Off Green Off

14:9 + Key Yellow Off Green

16:9 + Key Yellow Green Off

2 F EDH On Off Green Off

Off Off Off Off

01/03/2005 V1623_2OM.DOC Page 13 of 15

Page Menu Item Parameter /

Value ‘-‘ led ‘ ‘ led ‘+’ led

3 A Limiting Off Off Off Off

Set-up ear limit Off Yellow Off

3 B Operating Normal Off Off Off

Mode Engineering Yellow Yellow Yellow

Alignment Red Red Red

3 C Test Off Off Off Off

Patterns Staircase Off Off Yellow

Split Staircase Yellow Off Yellow

Black Off Yellow Off

(* Eng. Mode Edge of picture Off Off Red

Only) Split Edge Yellow Off Red

SDI Ramp Off Red Off

Split Ramp Yellow Red Off

2.5.3 Control Source

The lowest switch has three positions and selects the control source:

Rem Control is from the DART system. This requires the use of an external

controller running a suitable programme, which communicates with multiple

racks using the Dartnet protocol.

Local Control is from the front panel itself.

01/03/2005 V1623_2OM.DOC Page 14 of 15

2.6 INITIALISATION

When the unit powers up it will be reset to the same conditions as when power was removed until it is

changed. In the Remote control mode any changes will be made by the control system, but in Local

they will be made on the front panel.

In Local mode the control panel will start up at page 0, menu 0. This is also the case when it is switched

into remote mode.

There are separate stores for adjustments and parameters on the module for Local and Remote modes,

so the unit may change its settings when switched between the control modes.

3. OPERATION

3.1 ADJUSTMENT RANGES

The adjustment ranges on the main parameters are:

PARAMETER RANGE

Video Gain ±6dB (aggregate)

Chroma Gain ±6dB (aggregate)

Green Gain ±6dB (aggregate)

Blue Gain ±6dB (aggregate)

Red Gain ±6dB (aggregate)

Black Level ±100 levels (~100mV)

Since the gain components are subject to both the video, chroma and individual colour gains the applied

gains are compounded. However the overall gain limit is still ±6dB.

Since the control system does the gain compounding, there is no loss of signal integrity. For example a

video gain of +3dB and a chroma gain of -3dB will have no effect on the chrominance components at all,

so there will be no limiting or loss of resolution.

3.2 FUNCTION ORDER

The Black Level offset is applied before the gain stages. This is considered the best arrangement when

the offset is used to correct for an incorrect input, such as may occur with poor quality input signals.

3.3 INPUT FORMAT

The input format may be selected to be either Y,Pb,Pr or GBR. In addition to these formats variations

can be selected to handle set-up on luminance and GBR signals, or amplitude variations encountered

from certain video tape formats.

3.4 OUTPUT STANDARD

The output standard of the unit can be controlled in several ways. The module can be left to decide

automatically what standard to use according to the input reference signal, or forced to always produce

a certain standard.

When the reference fails the unit can be set to default to the last used standard or default to a given

standard. The output can also be selected to freerun, output Black or mute if the reference fails.

01/03/2005 V1623_2OM.DOC Page 15 of 15

3.5 Y/C DELAY AND PICTURE POSITION

The Y/C delay control will allow adjustments to be made for timing errors between the component

signal. It is only operational in the Y,Pb,Pr modes.

The Picture position allows timing adjustments to be made to align the Reference input with the video

inputs.

3.6 VERTICAL AND WIDE SCREEN BLANKING

Vertical Blanking is nominally set to blank all the lines during the vertical interval. It can however be

adjusted to allow extra lines through, removing a line of blanking per field with each adjustment, upto the

standards maximum.

Standard Field 1 Field 2

625 Line 6 - 22 Line 318 - 335

525 Line 10 - 19 Line 273 - 282

Wide screen blanking can be added to reduce the picture height to a 14:9 or 16:9 aspect ratio. The

value of the blanking level can also be set to Key mode, which will put the luminance channel to a digital

value of 63 during the active picture blanking section and change any other occurrence of 63 in the

active picture luminance channel to 64.

3.7 TEST PATTERN GENERATOR

The internal test pattern generator produces Colour Bars and Black, which are legal signals for

transmission plus, when in Engineering mode, Edge + centre of picture markers and SDI Ramp. All the

test patterns, except Black can also be put into Split screen mode, so half the picture is test pattern and

the other half Input video.

3.8 EDH

The V1623 contains an EDH generator. This means a correct EDH data packet is always created on

the output, when it is switched on.

3.9 SETUP EAR REMOVAL

When a 525 video input is used with set-up, it is not possible to accurately know where the pedestal

starts and stops, due to the specification differences between analogue and digital horizontal blanking.

Therefore sometimes small positive or negative pulses are present on the SDI output following set-up

removal. The set-up ear removal option will detect and remove any negative going pulses within the

uncertainty period at the start and end of the lines.

3.10 ENGINEERING AND ALIGNMENT MODE

The Engineering mode allows additional Test patterns to be selected, which are not legal signals for

transmission, Edge + Centre Picture Markers and SDI Ramp. It also allows selection of individual

output channels to provide Y only, Pb only, Pr only or colour output. (These signals and modes are

inhibited when not in Engineering mode).

The Alignment mode is only available from the front control panel when the module is in Local mode. It

allows an Engineer to align the video paths through the unit a single channel at a time onto the Y

output.

This manual suits for next models

1

Table of contents

Other VISTEK Media Converter manuals

Popular Media Converter manuals by other brands

H&B

H&B TX-100 Installation and instruction manual

Bolin Technology

Bolin Technology D Series user manual

IFM Electronic

IFM Electronic Efector 400 RN30 Series Device manual

GRASS VALLEY

GRASS VALLEY KUDOSPRO ULC2000 user manual

Linear Technology

Linear Technology DC1523A Demo Manual

Lika

Lika ROTAPULS I28 Series quick start guide

Weidmuller

Weidmuller IE-MC-VL Series Hardware installation guide

Optical Systems Design

Optical Systems Design OSD2139 Series Operator's manual

Tema Telecomunicazioni

Tema Telecomunicazioni AD615/S product manual

KTI Networks

KTI Networks KGC-352 Series installation guide

Gira

Gira 0588 Series operating instructions

Lika

Lika SFA-5000-FD user guide